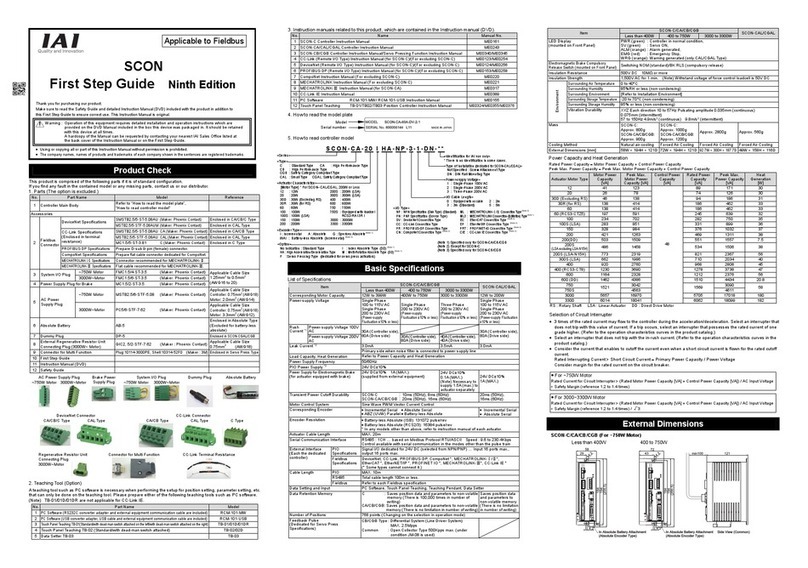

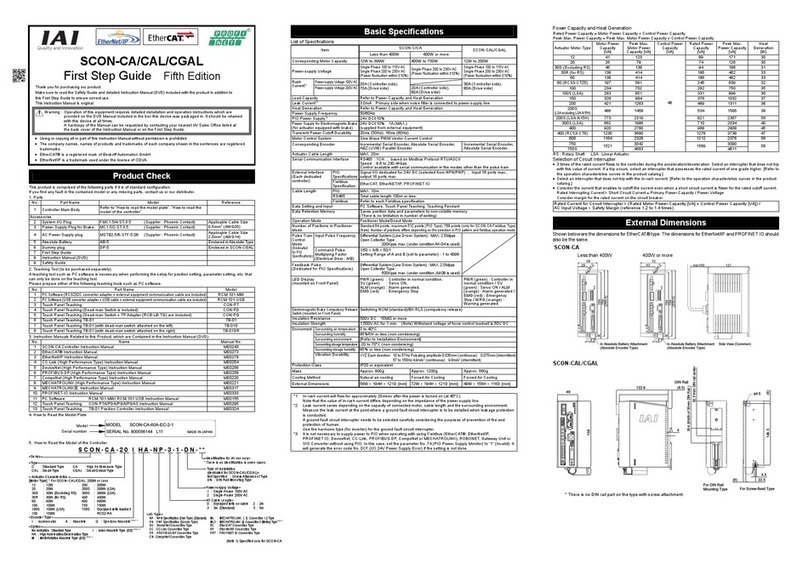

Starting Procedures

When using this product for the first time, make sure to avoid mistakes and incorrect wiring

by referring to the procedure below.

Troubleshooting

For X-SEL, the operation status can be checked with the status LEDs on the front panel.

● For DeviceNet ○: Lighting ●: OFF : Flashing

Monitor LED

MS NS

GN RD GN RD

Status Treatment

○ − ○ − In normal operation

○ − ● ●

Waiting for master to

finish node address

duplication check

● Confirm that the communication speed of the mater and all the

slaves are set the same.

After correcting the settings, reboot the system.

● Confirm that the connectors are connected correctly.

○ − −

Waiting for the completion

of connection with the master

● Confirm if the master is operating with no abnormality.

● Confirm that the controller is registered in the scan list on the master.

− ○ ● ● Hardware error ● Please contact us.

−

● ● Error in DIP switch

setting

●

Confirm that the communication speed is set the same as the master setting.

● Confirm if the configuration setting is established correctly.

○ − − ○

Node addresses are duplicated

or busoff (communication stop

caused by data error being

repeated) is detected.

● Correct the node address, and then reboot the system.

● Check the influence of noise, e.g. check if there is a source of noise

nearby, or if the communication cable is laid parallel to a power line.

○ − −

Communication timeout

●

Confirm that the communication speed is set the same as the master setting.

NS repeats to light in green

and flash in green. Or, NS

repeats to flash in red and

green.

Communication error ● Confirm that the controller is registered in the scan list on the master.

● Confirm that the I/O area is not duplicated with another slave.

● Confirm that the I/O area is not exceeded over the master unit

allowable area (for fixed assignment).

● For CC-Link ○: Lighting ●: OFF : Flashing

STATUS 1 STATUS 0 Status

○ ○ This status does not exist

○ ● ●

Error occurred (CRC error, station number setting error or communication speed setting error)

● From the power being on or software reset to the completion of CC-Link initializing

● ○ Data exchanged in normal condition

● ●

Short in power supply system, broken remote station power supply or short of communication cable

○ This status does not exist

● Setting of station number or communication speed is changed during a communication

● For PROFIBUS

LED Color Display condition Description (meaning of indication)

Lighting On the fieldbus line and communication in normal condition

GN Flashing Off the fieldbus line

STATUS 1

OR Flashing Communication error occurred

Lighting In normal operation

GN Flashing Preparing the operation

STATUS 0

OR Lighting Error is detected in communication related hardware while

preparing the operation.

Troubleshooting

The following alarm displays are frequently generated at the start-up operation. Take the measure referring to the following description.

When any of the other alarms is output, refer to the operation manual.

Status display Status contents Cause and Remedy

During emergency-stop It is not an alarm.

• It is generated when the emergency stop switch in the teaching

pendant or the personal computer application software is not

cancelled. In such case, cancel it.

• It is generated when the personal computer cable is not

connected to the emergency stop box.

• Check the emergency stop circuit.

Safety gate remains open.

Deadman switch OFF

It is not an alarm.

• It is generated when the system I/O ENB signal is opened.

Check the ENB signal. (It is generated when the safety gate is

open. Close the safety gate.)

• It is generated when the AUTO/MANU switch has been set to

“MANU” and the personal computer or the teaching pendant is

not connected. Connect the personal computer or the teaching

pendant or set the AUTO/MANU switch to “AUTO”.

• When the actuator is to be started up, hold the deadman switch

on the teaching pendant to turn it on.

AC Power Interruption

Momentary Power Failure

Power Voltage Drop

It is generated when the power voltage is not supplied. It will be

generated, for example, in the case that the 100VAC is supplied to

the controller with 200VAC specified. Check the power supply.

Absolute Data Backup Battery

Voltage Error

It will be generated in the case that the battery has not been

attached, or the battery voltage is dropped.

In the case of the actuator for the single-axis robots or Cartesian

robots with the absolute data specifications, it is generated when

the power is connected for the first time.

Perform the absolute reset.

Encoder Disconnection Error It is generated when the cable is broken or the encoder cable is not

connected to the controller. Check the wiring.

Encoder Reception Time Out It is generated when the encoder is broken, the cable is broken or

the encoder cable is not connected to the controller. Check the

wiring.

24V I/O error

DO output current error

It is generated when the +24V power for I/O is not supplied. Check

the power supply.

(How to start up the controller without connecting the I/O 24V power)

Set the I/O parameter No. 10 to No. 13 corresponding to the

standard or extended I/O board to “0”.

FieldBus Error It is generated when the field bus link connection is not established.

Check the link cable connection, I/O parameter and PLC parameter

settings.

(How to start up the controller without connecting the field bus)

Set the I/O parameter No. 10 to No. 13 corresponding to the

standard or extended I/O board to “0”.

RC Gateway Serious Breakdown

Error

When the RC gateway is used and an error occurs in the controller

connected SIO (serial communication), it is generated.

The following causes are possible.

• All effective RC axes are missing (not recognized).

→

A cable disconnection or broken wire is possible. Check the wiring.

• The power switch on the main CPU shows 0V.

→ Set the +5V power switch to right side (+5V supply side).

• The DPRAM access right can not be obtained for one hour or

more in the connected SIO.

→ Check the parameters for the X-SEL or RC controller.

•

A serious error such as a CPU error is caused in the connected SIO.

→ It is caused by the hardware breakdown. Contact IAI.

Head Office: 577-1 Obane Shimizu-KU Shizuoka City Shizuoka 424-0103, Japan

TEL +81-54-364-5105 FAX +81-54-364-2589

website: www.iai-robot.co.jp/

Ober der Röth 4, D-65824 Schwalbach am Taunus, Germany

TEL 06196-88950 FAX 06196-889524

SHANGHAI JIAHUA BUSINESS CENTER A8-303, 808, Hongqiao Rd. Shanghai 200030, China

TEL 021-6448-4753 FAX 021-6448-3992

website: www.iai-robot.com

Technical Support available in USA, Europe and China

Head Office: 2690 W. 237th Street, Torrance, CA 90505

TEL (310) 891-6015 FAX (310) 891-0815

Chicago Office: 110 East State Parkway, Schaumburg, IL 60173

TEL(847) 908-1400 FAX (847) 908-1399

TEL (678) 354-9470 FAX (678) 354-9471

website: www.intelligentactuator.com

Atlanta Office: 1220 Kennestone Circle, Suite 108, Marietta, GA 30066

825 PhairojKijja Tower 7th Floor, Bangna-Trad RD., Bangna, Bangna, Bangkok 10260, Thailand

TEL +66-2-361-4458 FAX +66-2-361-4456

website:www.iai-gmbh.de

website:www.iai-robot.co.th

Set-up for operation is complete. (Start adjusting the system operation.)

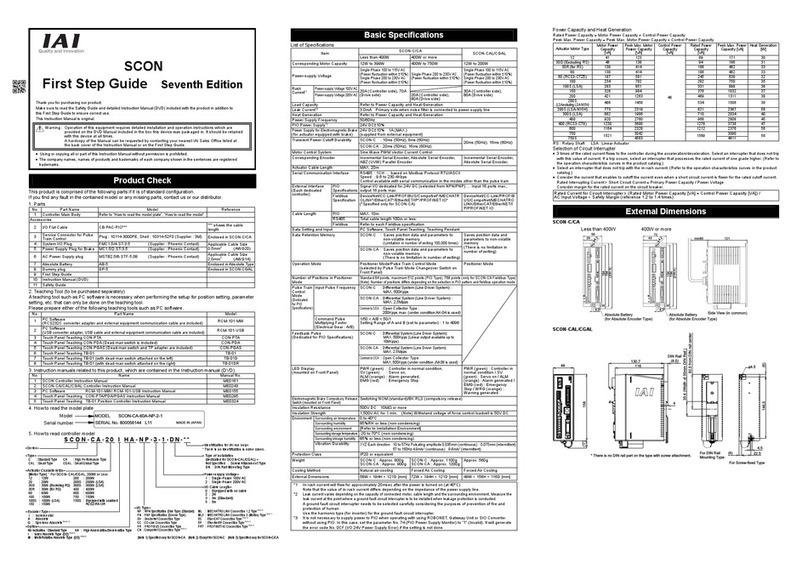

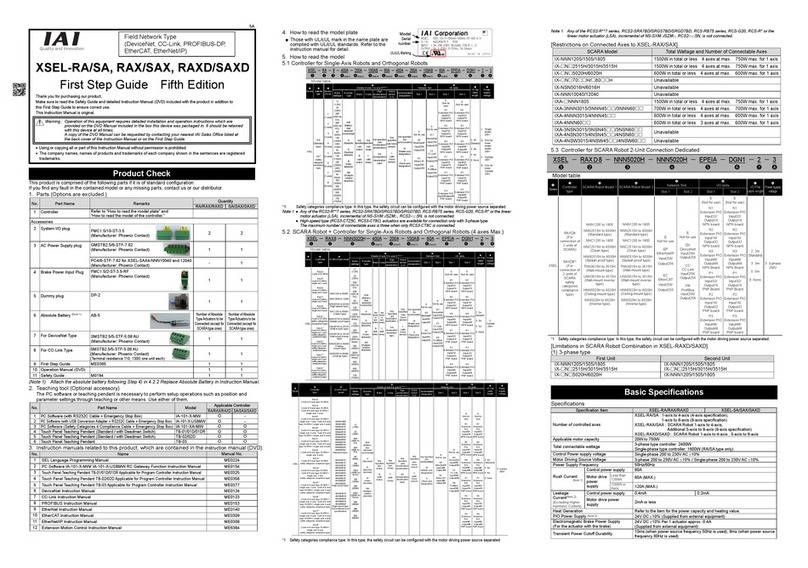

Installation and Wiring

Install the controller and actuator and

perform wiring according to the instruction

manual and the contents in this book.

Point Check Item

•

Have you performed the frame grounding (FG) and protective earthing (PE)?

•

Has the noise countermeasure been taken?

Ye s

Power Supply and Alarm Check Deal with each condition depending

on the status display.

(Refer to the Treatments in Error

Condition )

Servo ON Check Item

Ye s

Ye s

Check Item

Is shown for

Parameter Setting

Check of Safety Circuit

Check that the emergency stop circuit (or

motor drive power cutoff circuit) operates

normally to turn off the servo.

Check the emergency stop circuit.

Homing Execution

Check of Packed Items

Ye s

Ye s

No

No

Confirming the operation of the actuator

Confirm that the full stroke operation is performed without

any trouble with the jog operation.

Ye s

Ye s

No

No

No

No

Connect the personal computer or teaching

pendant, set the AUTO/MANU switch to the

[MANU] side and inject the power.

Are there all the delivered items?

*1 For the single axis robots and Cartesian-type robots with absolute design and SCARA robots,

the homing operation is not required.

When the unit is set to Vertical and the servo

ON/OFF is repeated, it might descend slightly

due to its own weight. Therefore, be careful

not to catch your hand or damage the work.

•It is recommended to set the safety operation to Enable

for the first movement for safety purposes.

•When it is installed vertically and the brake release switch is set

to [RLS] side, it might descend due to its own weight. Therefore,

be careful not to catch your hand or damage the handle.

Has the motor cable connected?

Connect the motor cable.

Turn ON the servo motor with the personal

computer or teaching pendant operation.

Check on the monitor of the

PC or the teaching pendant

that the servo is ON.

Is the servo ON?

Set the parameters including I/O parameter with the personal

computer or teaching pendant operation.

If the communication is not established, set the I/O parameter

#18 to 0 to cancel the monitoring of the fieldbus error.

When the alarm is output, deal with it

after confirming the alarm description,

using the personal computer or teaching

pendant operation.

Home the actuator with personal computer

or teaching pendant operation.

the status display?

*1

Contact our distributor or us.

Check Item

Is the communication established?

Turn on all the top level systems and confirm the communication

establishment with the LED lights.

Establish the communication.

Refer to the Operation Manual (CD) or the Operation Manual of the master unit.

Check the communication settings again.

(Note) First, check the conditions of station number settings,

communication speed, terminator and the wiring.

Establishing the communication

Manual No.: ME0230-9A