RCP2/RCA/RCS2/RCS3 Actuator

Slider Type/Rod Type/

Arm Type/Flat Type

First Step Guide Tenth Edition

Thank you for purchasing our product.

Make sure to read the Safety Guide and detailed Instruction Manual (DVD) included with the product in addition to

this First Step Guide to ensure correct use.

This Instruction Manual is original.

•Using or copying all or part of this Instruction Manual without permission is prohibited.

•The company names, names of products and trademarks of each company shown in the sentences are registered

trademarks.

Product Check

This product is comprised of the following parts if it is of standard configuration.

If you find any fault in the contained model or any missing parts, contact us or our distributor.

1. Parts (The option is excluded.)

No. Part Name Model Quantity Remarks

1 Actuator Main Body Refer to “2. How to read the model plate”,

“3. How to read the model No.” 1

Accessories

2 Motor • Encoder Cable*1 1 set

3 Home Position Marking Sticker 1 Packaged in slider type

4 Nut Refer to list below

5 First Step Guide 1

6 Instruction Manual (DVD) 1

7 Safety Guide 1

*1 Please refer to the wiring layout for the enclosed motor cable and encoder cable.

(List of Included Nut Type)

Model No. Nut

M10×1.25

Nut

M12×1.25

Nut

M14×1.5

Nut

M20×1.5

Nut

M22×1.5

Square Nut

6×6 M4

Square Nut

7×7 M4

Square Nut

10×10 M6

RCP2-RA3C 1

RCP2-RA4C 1 4

RCP2-RA6C 1 4

RCP2-RA8C 1

RCP2-RA10C 1

RCP2-RA3R 1

RCP2-RA4R 1 4

RCP2-RA6R 1 4

RCP2-RA8R 1

RCP2-RGS4C 4

RCP2-RGS6C 4

RCP2-RGD4C 4

RCP2-RGD6C 4

RCP2-SRA4R 1

RCA-SRA4R 1

RCS2-RA7AD 1

RCS2-RA7BD 1

RCS2-SRA7BD 1

RCS2-RA5C

4 or 8*1

RCS2-RA5R 1

4 or 8*1

RCS2-RGD5C

4 or 8*1

*1 Stroke 100mm or less : 4 Units, stroke 100mm or more : 8 Units

Model No. Nut A

M26×1.5

Nut B

M35×1.5

Nut C

M8×1.5

Nut A

M30×1.5

Nut B

M40×1.5

Nut C

M10×1.5

RCA-RA3C 1 1 1

RCA-RA4C 1 1 1

RCA-RA3D 1 1 1

RCA-RA4D 1 1 1

RCA-RA3R 2 1

RCA-RA4R 2 1

RCA-RGS3C 1 1

RCA-RGS4C 1 1

RCA-RGS3D 1 1

RCA-RGS4D 1 1

RCA-RGD3C 1 1

RCA-RGD4C 1 1

RCA-RGD3D 1 1

RCA-RGD4D 1 1

RCA-RGD3R 2

RCA-RGD4R 2

RCS2-RA4C 1 1 1

RCS2-RA4D 1 1 1

RCS2-RA4R 2 1

RCS2-RGS4C 1 1

RCS2-RGS4D 1 1

2. How to read the model plate

3. How to read the Model No.

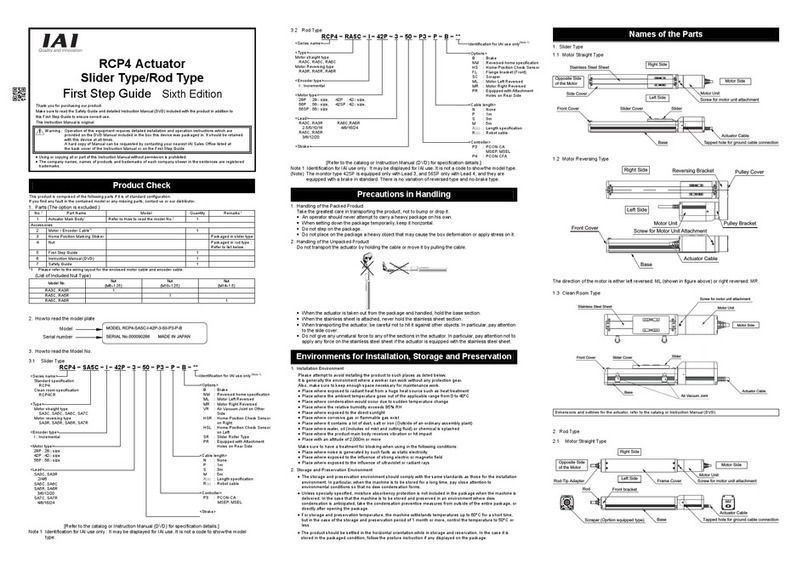

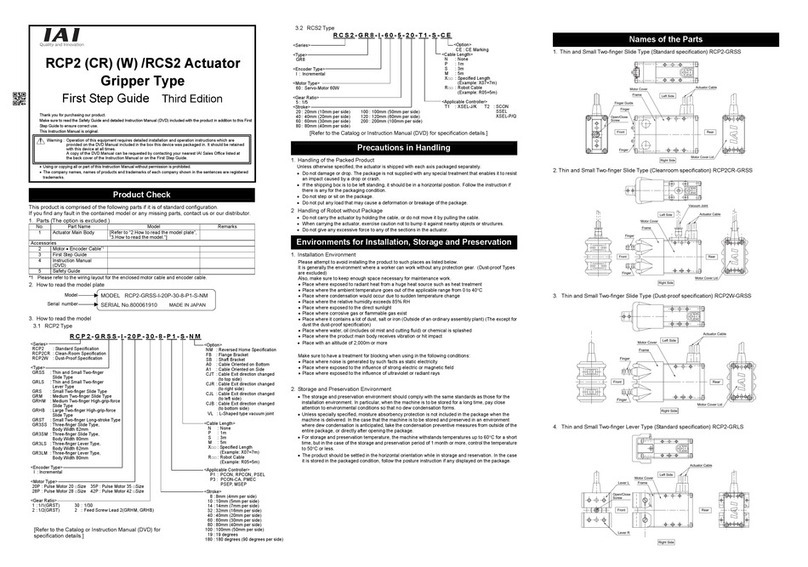

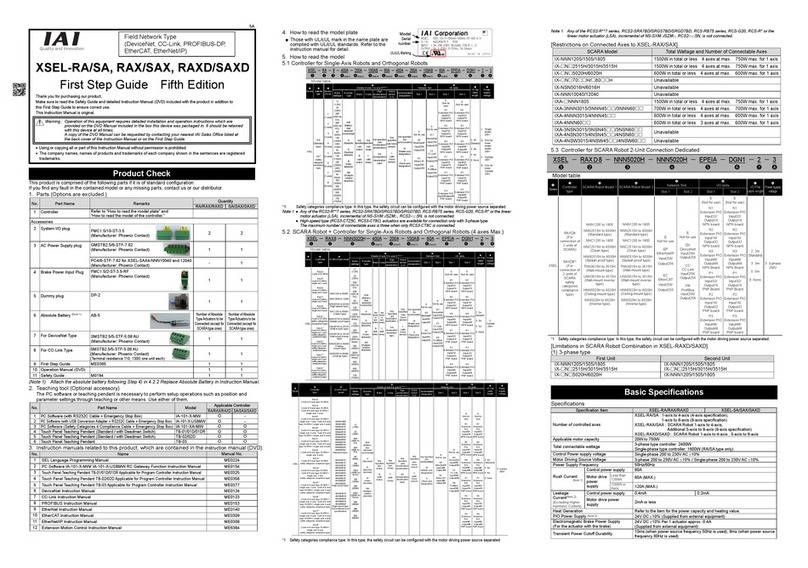

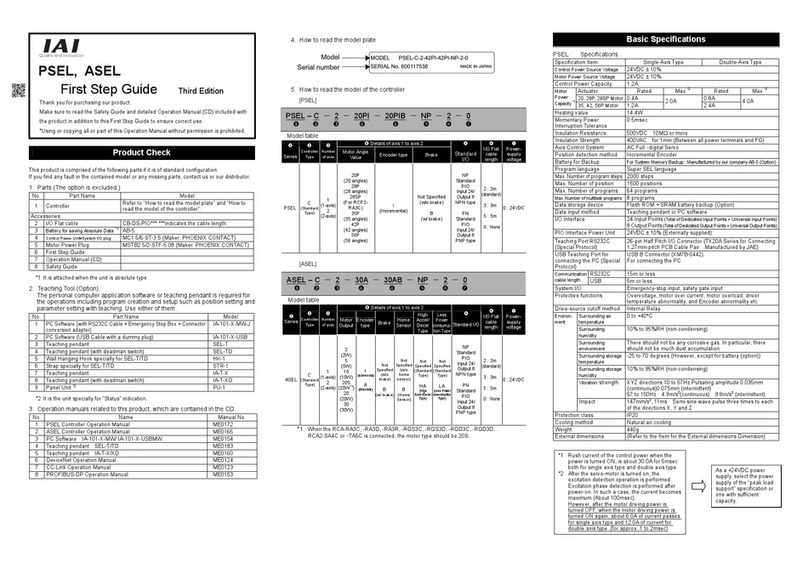

3.1 Slider Type

3.1.1 RCP2 Actuator

[Refer to the catalog or Instruction Manual (DVD) for specification details.]

3.1.2 RCA Actuator

Note : Models applicable for the battery-less absolute type are RCA-SA4C/R, SA5C/R, SA6C/R,

RCACR-SA4C, SA5C and SA6C.

[Refer to the catalog or Instruction Manual (DVD) for specification details.]

3.1.3 RCS2 Actuator

[Refer to the catalog or Instruction Manual (DVD) for specification details.]

3.1.4 RCS3 Actuator

Note : Models applicable for the battery-less absolute type are RCS2-SA4C/R, SA5C/R,

SA6C/R, SA7C/R, RCS2CR-SA4C, SA5C, SA6C, SA7C, RCS3-SA8C/R, SS8C/R,

RCS3CR-SA8C, SS8C.

[Refer to the catalog or Instruction Manual (DVD) for specification details.]

3.2 Rod Type

3.2.1 RCP2 Actuator

[Refer to the catalog or Instruction Manual (DVD) for specification details.]

3.2.2 RCA Actuator

[Refer to the catalog or Instruction Manual (DVD) for specification details.]

3.2.3 RCS2 Actuator

Note : Models applicable for the battery-less absolute type are RCS2-RA5C/R, RGS5C and RGD5C.

[Refer to the catalog or Instruction Manual (DVD) for specification details.]

*1 This may be displayed for the manufacturing reason.(This is not to indicate the manufacturing model code.)

Model

Serial number

MODEL RCP2-SA5C-I-42P-12-50-P1-P-BE

SERIAL No.600090266 MADE IN JAPAN

Note : For Absolute Type, there are encoder types A and TA.

Check the model types of the actuator and the controller when the controller is one of those listed below. In the

case the encoder type differs from what is indicated on the label, it may be necessary to make some changes to

the parameters. Please contact your nearest IAI sales office. Using the controller that requires parameter

changes will cause D67 (Motor/Encoder Structure Information) Error. However, it would not cause malfunction of

the product.

[Applicable Controllers] XSEL-J/K, XSEL-P/Q/R/S, SSEL

RCP2-SA5C-I-42P-12-50-P1-P-BE-**

<Series Name>

Standard Type Clean-Room Type

RCP2 RCP2CR

<Type>

Aluminum-Based Type

SA5C, SA6C

SA7C

Steel-Based Type

SS7C, SS8C

Steel-Based, High-Speed Type

HS8C

Aluminum-Based, Motor-Reversing Type

SA5R, SA6R

SA7R

Steel-Based, Motor-Reversing Type

SS7R, SS8R

Steel-Based, High-Speed, Motor-Reversing Type

HS8R

<Encoder Type>

I : Incremental

<Motor Type>

42P : 42 □Size 56P : 56 □Size 86P : 86 □Size

<Lead>

3 : 3mm 10 : 10mm , 4 : 4mm 12 : 12mm

5 : 5mm 16 : 16mm , 6 : 6mm 20 : 20mm

8 : 8mm 30 : 30mm

Identification for IAI use only*1

<Option>

B : Brake

BE : Brake (Cable on end)

BL : Brake (Cable on left)

BR : Brake (Cable on right)

NM : Reversed-Home Type

ML : Motor Reversing from Left Side

MR : Motor Reversing from Right Side

SR : Slider Roller Specification Type

VR : Suction Joint Reversed Type

<Cable Length>

N : None, P : 1m

S : 3m , M : 5m

X□□ : Specified Length

R□□ : Robot Cable

<Controller>

P1: PSEL, PCON-C/CG

PCON-CF, PCON-CY

PCON-SE, PCON-PL/PO

P3: PCON-CA, PMEC

PSEP, MSEL, MCON

<Stroke>

Identification for IAI use only*1

<Option>

B : Brake

BE : Brake (Cable on end)

BL : Brake (Cable on left)

BR : Brake (Cable on right)

FT : Foot Bracket

HA : High Accel/Decel Type

LA : Power Saving Type

HS : Home-Check Sensor

NM : Reversed-Home Type

SR : Slider Roller Specification Type

SS : Slider Spacer

ML : Motor Reversing from Left Side

MR : Motor Reversing from Right Side

VR : Suction Joint Reversed Type

<Cable Length>

N : None P : 1m S : 3m

M : 5m X□□: Specified Length

R□□ : Robot Cable

<Controller>

A1: ASEL A3: AMEC A5: ACON-CA

ACON-C/CG ASEP ACON-CB

ACON-CY MSEP MCON

ACON-SE

ACON-PL/PO

RCA-SA4C-I-20-10-50-A1-P-B-**

<Stroke>

<Series Name>

Standard Type Clean-Room Type

RCA RCACR

<Type>

Coupling Type Built-in Type

Aluminum-Based Type Aluminum-Based Type

SA4C, SA5C SA4D, SA5D

SA6C SA6D

Steel-Based Type

SS4D, SS5D

SS6D

Aluminum-Based,

Motor-Reversing Type

SA4R, SA5R

SA6R

<Encoder Type>

I : Incremental A : Absolute WA : Battery-less Absolute

<Motor Type>

20 : 20W 30 : 30W

<Lead>

2.5 : 2.5mm 6 : 6mm

3 : 3mm 10 : 10mm

5 : 5mm 12 : 12mm

20 : 20mm

RCS2-SA4C-I-20-10-50-A1-P-B-**

<Series Name>

Standard Type Clean-Room Type

RCS2 RCS2CR

<Type>

Coupling Type

Aluminum-Based Type Steel-Based Type

SA4C, SA5C SS7C, SS8C

SA6C, SA7C

Built-in Type

Aluminum-Based Type

SA4D, SA5D

SA6D

Aluminum-Based, Motor-Reversing Type

SA4R, SA5R

SA6R, SA7R

Steel-Based, Motor-Reversing Type

SS7R, SS8R

<Encoder Type>

I : Incremental A : Absolute TA : Absolute

WA : Battery-less Absolute

<Motor Type>

20 : 20W 60 : 60W 150 : 150W

30 : 30W 100 : 100W

<Lead>

2.5 : 2.5mm 6 : 6mm 12 : 12mm

3 : 3mm 8 : 8mm 16 : 16mm

4 : 4mm 10 : 10mm 20 : 20mm

5 : 5mm

Identification for IAI use only*1

<Option>

B : Brake

BE : Brake (Cable on end)

BL : Brake (Cable on left)

BR : Brake

FT : Foot Bracket

HA : High Accel/Decel Type

HS : Home-Check Sensor

NM : Reversed-Home Type

SR : Slider Roller Specification Type

SS : Slider Spacer

ML : Motor Reversing from Left Side

MR : Motor Reversing from Right Side

VR : Suction Joint Reversed Type

CE : CE Marking

<Cable Length>

N : None

P : 1m

S : 3m

M : 5m

X□□ : Specified Length

R□□ : Robot Cable

<Controller>

T1: XSEL-J/K

T2: SCON

SSEL

XSEL-P/Q/R/S

<Stroke>

RCS3-SA8C-I-100-5-50-T1-P-B-**

<Series Name>

Standard Type Clean-Room Type

RCS3 RCS3CR

<Type>

Aluminum-Based Type Steel-Based Type

SA8C SS8C

Aluminum-Based Reversing Type Steel-Based Reversing Type

SA8R SS8R

<Encoder Type>

I : Incremental A : Absolute TA : Absolute

WA : Battery-less Absolute

<Motor Type>

100 : 100W 150 : 150W

<Lead>

5 : 5mm 20 : 20mm

10 : 10mm 30 : 30mm

<Stroke>

<Controller>

T1: XSEL-J/K

T2: SCON, SSEL, XSEL-P/Q

Identification for IAI use only*1

<Option>

B : Brake

NM : Reversed-Home Type

A1S : Cable Exit on Left Side

A1E : Cable Exit on Left of Rear Side

A3S : Cable Exit on Right Side

A3E : Cable Exit on Right of Rear Side

MLE : Motor Reversed on Left Side,

Cable Exit on Rear Side

MLS : Motor Reversed on Left Side,

Cable Exit on a Side

MRE : Motor Reversed on Right Side,

Cable Exit on Rear Side

MRS : Motor Reversed on Right Side,

Cable Exit on a Side

SR : Slider Roller Specification Type

VL : L-shaped Vacuum Joint Type

VN : No Vacuum Joint

CE : CE Marking

<Cable Length>

N : None P : 1m S:3m

M :5m X□□ : Specified Length

R□□ : Robot Cable

RCA-RA3C-I-20-10-50-A1-P-B-**

<Series Name>

Standard Type

RCA

Dust and Splash-Proof Type

RCAW

<Type>

Standard Type

Coupling Type

RA3C, RA4C

Built-in Type

RA3D, RA4D

Motor-Reversing Type

RA3R, RA4R

Single-Guide Type

Coupling Type

RGS3C, RGS4C

Built-in Type

RGS3D, RGS4D

Double-Guide Type

Coupling Type

RGD3C, RGD4C

Built-in Type

RGD3D, RGD4D

Motor-Reversing Type

RGD3R, RGD4R

Short Length Type

SRA4R

Short Length Type

With Single Guide

SRGS4R

Short Length Type

With Double Guide

SRGD4R

Identification for IAI use only*1

<Option>

B : Brake

FT : Foot Bracket

FT2 : Foot Bracket (right attached)

FT4 : Foot Bracket (left attached)

GS2 : Single Guide, right attached

FL : Flange Bracket (front)

FLR : Flange Bracket (rear)

HA : High Accel/Decel Type

HS : Home-Check Sensor

LA : Power Saving Type

NJ : Knuckle Joint

NM : Reversed-Home Type

TRF : Trunnion Bracket (front)

TRR : Trunnion Bracket (rear)

QR : Clevis Bracket

RP : Rear Attachment Plate

<Cable Length>

N : None

P : 1m

S : 3m

M : 5m

X□□ : Specified Length

R□□ : Robot Cable

<Controller>

A1: ASEL, ACON-C/CG

ACON-CY, ACON-SE

ACON-PL/PO

A3: AMEC, ASEP, MSEP

A5: ACON-CA, ACON-CB, MCON

<Encoder Type>

I : Incremental

A : Absolute

<Motor Type>

20 :20W

30 :30W

<Lead>

2.5 : 2.5mm

3 : 3mm

5 : 5mm

6 : 6mm

10 : 10mm

12 : 12mm

<Stroke>

RCS2-RA4C-I-20-12-50-T1-P-B-**

<Series Name>

Standard Type

RCS2

Dust and Splash-Proof Type

RCS2W

<Type>

Standard Type

Coupling Type

RA4C, RA5C

Built-in Type

RA4D, SRA7BD

RA7AD, RA7BD

Motor-Reversing Type

RA4R, RA5R

RA13R

Single-Guide Type

Coupling Type

RGS4C, RGS5C

Built-in Type

RGS4D, SRGS7BD

RGS7AD, RGS7BD

Double-Guide Type

Coupling Type

RGD4C, RGD5C

Built-in Type

RGD4D, SRGD7BD

RGD7AD, RGD7BD

Motor-Reversing Type

RGD4R

Short Length Type

SRA7BD

With Single Guide

SRGS7BD

With Double Guide

SRGD7BD

Identification for IAI use only*1

<Option>

B : Brake

B : Brake (RA13R brake box equipped)

BN : Brake (RA13R brake box excluded)

FT : Foot Bracket

FL : Flange Bracket (front)

FLR : Flange Bracket (rear)

HA : High Accel/Decel Type

HS : Home-Check Sensor

NJ : Knuckle Joint

NM : Reversed-Home Type

TRF : Trunnion Bracket (front)

TRR : Trunnion Bracket (rear)

QR : Clevis Bracket

RP : Rear Attachment Plate

A1 to A3 :

Varied in connector cable orientation

ML : Motor-Reversing Type (Standard)

MR : Motor-Reversing Type

MT1, MT2, MT3 :

Motor Reversing from Upper Side

MR1, MR2 :

Motor Reversing from Right Side

ML1, ML2 :

Motor Reversing from Left Side

GS2 to GS4 :

Varied in guide attachment orientation

LCT : With loadcell and cable track

LCN : Without loadcell and cable track

CE : CE Marking

<Cable Length>

N : None P : 1m S : 3m

M : 5m X□□: Specified Length

R□□: Robot Cable

<Encoder Type>

I : Incremental A : Absolute

TA : Absolute

WA : Battery-less Absolute

<Motor Type>

20 : 20W

30 : 30W

60 : 60W

100 : 100W

150 : 150W

750 : 750W

<Lead>

1.25 : 1.25mm

2.5 : 2.5mm

3 : 3mm

4 : 4mm

6 : 6mm

8 : 8mm

12 : 12mm

16 : 16mm

<Stroke>

<Controller>

T1: XSEL-J/K

T2: SCON

SSEL

XSEL-P/Q/R/S

RCP2-RA2C-I-20P-1-50-P1-P-FL-**

<Series Name>

Standard Type

RCP2

Dust and Splash-Proof Type

RCP2W

<Type>

Standard Type Reversing Type

RA2C, RA3C RA3R, RA4R

RA4C, RA6C RA6R, RA8R

RA8C, RA10C

Single-Guide Type

RGS4C, RGS6C

Double-Guide Type

RGD3C, RGD4C

RGD6C

Short Length Type

SRA4R

Short Length Type

With Single Guide

SRGS4R

Short Length Type

With Double Guide

SRGD4R

<Encoder Type>

I : Incremental

<Motor Type>

20P : 20 □Size

28P :28 □Size

35P : 35 □Size

42P : 42 □Size

56P : 56 □Size

86P : 86 □Size

Identification for IAI use only*1

<Option>

B : Brake

FL : Flange Bracket (front)

FLR : Flange Bracket (rear)

FT : Foot Bracket

FT2 : Foot Bracket (right attached)

FT4 : Foot Bracket (left attached)

GS2 : Single Guide, right attached

GS3 : Single Guide, bottom attached

GS4 : Single Guide, left attached

NM : Reversed-Home Type

A1 : Connector cable oriented on left

A2 : Connector cable oriented toward rod

A3 : Connector cable oriented on right

<Cable Length>

N : None

P : 1m

S : 3m

M : 5m

X□□ : Specified Length

R□□ : Robot Cable

<Controller>

P1: PSEL P3: PCON-CA

PCON-C/CG PMEC

PCON-CF PSEP

PCON-CY MSEL

PCON-SE MCON

PCON-PL/PO

<Lead>

1 : 1mm 8 : 8mm

2.5 : 2.5mm 10 : 10mm

4 : 4mm 16 : 16mm

5 : 5mm

<Stroke>

Warning : Ope