ME0392-4C

Contents

Safety Guide ·················································································· Intro-1

Precautions for Handling ··································································· Intro-8

Precautions for PC connection to SEL unit

grounded at positive terminal of 24V DC power supply····················· Intro-14

International Standard Compliance······················································ Intro-15

About UL/cUL ················································································· Intro-16

Actuator Coordinate System ······························································ Intro-17

Chapter 1 RSEL System

1.1 Overview (About RSEL System)·················································· 1-1

1.2 Features ················································································ 1-2

1.3 Specifications·········································································· 1-5

1.3.1 General specifications ··········································································· 1-5

1.3.2 Environmental conditions ········································································ 1-6

1.3.3 Supper source specifications ··································································· 1-6

1.3.4 Specifications at control part ···································································· 1-7

1.3.5 Usage temperature range········································································ 1-8

1.3.6 General specifications ············································································ 1-8

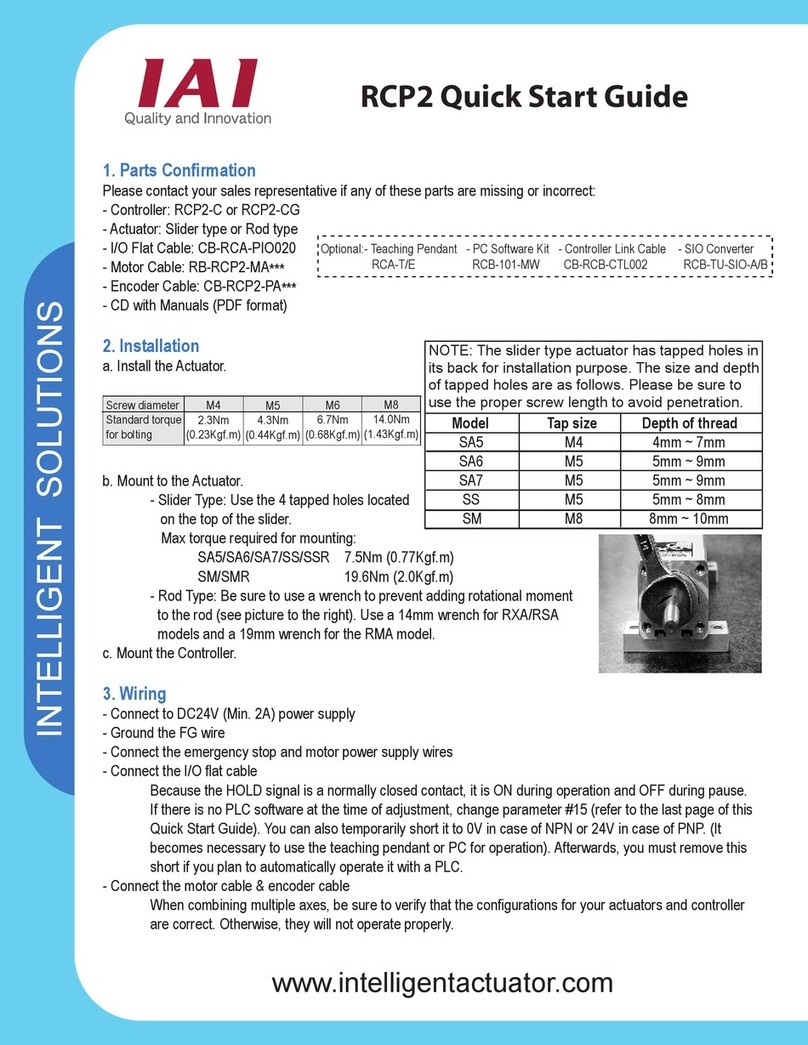

1.4 Installation·············································································· 1-9

1.4.1 Installation conditions ············································································· 1-9

1.4.2 Installation and mounting ········································································ 1-10

1.4.3 Noise countermeasures and mounting method ············································ 1-11

Chapter 2 System Configuration and Power Specifications

2.1 System Configuration································································ 2-1

2.1.1 System configuration diagram ·································································· 2-1

2.1.2 Configuration unit ·················································································· 2-2

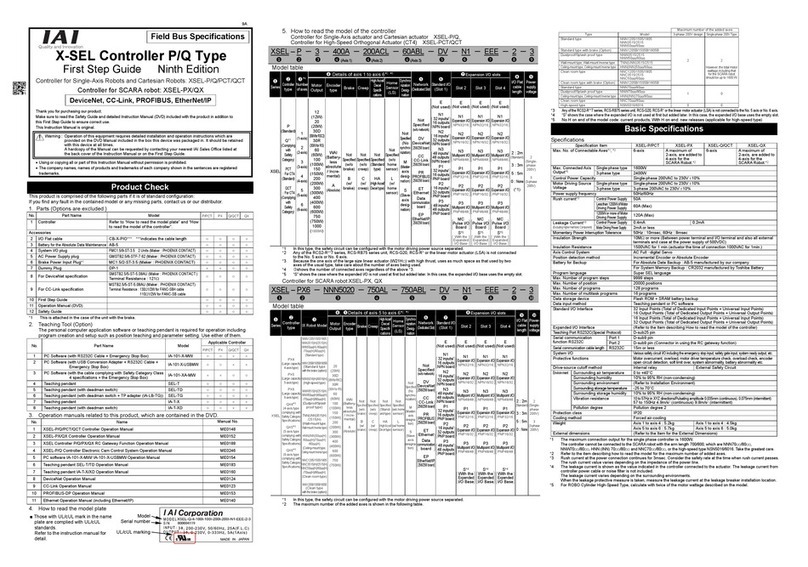

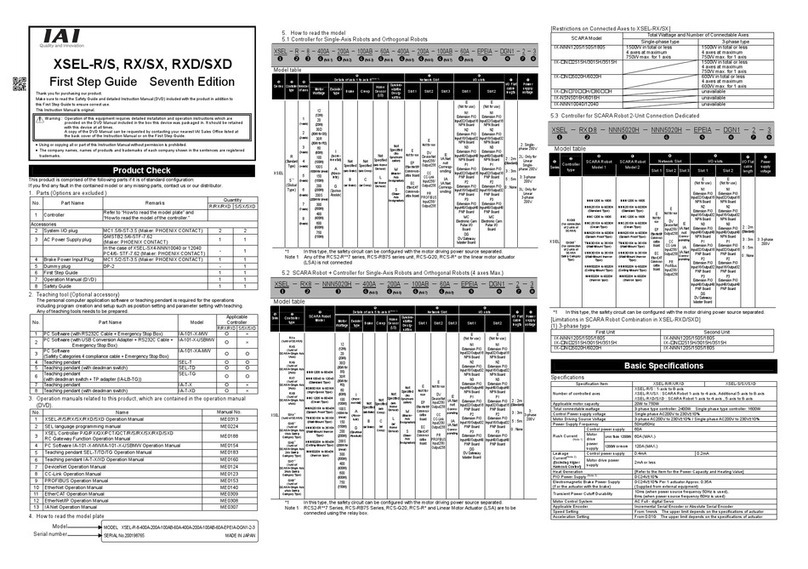

2.1.3 Model code ·························································································· 2-5

2.1.4 Unit list ································································································ 2-9

2.1.5 Set model code for 6-axis cartesian robot (CRS series) ································· 2-10

2.1.6 Teaching tool (option) ············································································· 2-11

2.2 Power Supply Capacity ····························································· 2-12

2.2.1 Power Supply Capacity··········································································· 2-14

2.2.2 Unit connection restrictions······································································ 2-17

ME0392-4C

2.3 In-Rush Current ······································································· 2-22

2.4 Generated Heat ······································································· 2-24

2.5 Rush Current Sequence ···························································· 2-25

2.6 Drive-Source Cutoff ·································································· 2-26

2.6.1 Drive-source cutoff circuit specifications ····················································· 2-26

2.6.2 Drive-source cutoff circuit wiring example ··················································· 2-27

2.6.3 Category 3 or category 4 configuration example ·········································· 2-29

Chapter 3 Specifications of Each Unit

3.1 SEL Unit, Terminal Unit ····························································· 3-1

3.1.1 Overview ····························································································· 3-1

3.1.2 Model code ·························································································· 3-2

3.1.3 Component ·························································································· 3-4

3.1.4 Part names/Functions············································································· 3-5

3.1.5 External dimensions ··············································································· 3-29

3.2 24V Driver Unit, Fun Unit ··························································· 3-31

3.2.1 Overview ····························································································· 3-31

3.2.2 Model code ·························································································· 3-32

3.2.3 Components ························································································· 3-34

3.2.4 Part names/Functions············································································· 3-35

3.2.5 External dimensions ··············································································· 3-46

3.3 200V Power Supply Unit, for 200V Terminal Unit····························· 3-48

3.3.1 Overview ····························································································· 3-48

3.3.2 Model code ·························································································· 3-50

3.3.3 Components ························································································· 3-53

3.3.4 Part names/Functions············································································· 3-54

3.3.5 External dimensions ··············································································· 3-61

3.4 200V Driver Unit, Fan Unit for 200V Driver ···································· 3-63

3.4.1 Overview ····························································································· 3-63

3.4.2 Model code ·························································································· 3-65

3.4.3 Components ························································································· 3-68

3.4.4 Part names/Functions············································································· 3-69

3.4.5 External dimensions ··············································································· 3-76

3.4.6 Driver stop circuit··················································································· 3-78