RCS3 Actuator

Loadcell-equipped Rod Type

First Step Guide Third Edition

Thank you for purchasing our product.

Make sure to read the Safety Guide and detailed Instruction Manual (DVD) included with the product in addition to

this First Step Guide to ensure correct use.

This Instruction Manual is original.

• Using or copying all or part of this Instruction Manual without permission is prohibited.

• The company names, names of products and trademarks of each company shown in the sentences are

registered trademarks.

Product Check

The standard configuration of this product is comprised of the following parts.

If you find any fault or missing parts, contact your local IAI distributor.

1. Parts (Except with Option)

No. Part Name Model Quantity Remarks

1 Actuator Main Body Refer to “How to read the model No.” 1

Accessories

2 Motor • Encoder Cable (Note 1) 1

3 First Step Guide 1

4 Instruction Manual (DVD) 1

5 Safety Guide 1

Note 1 The motor/encoder cables refer to wiring for the applicable cables.

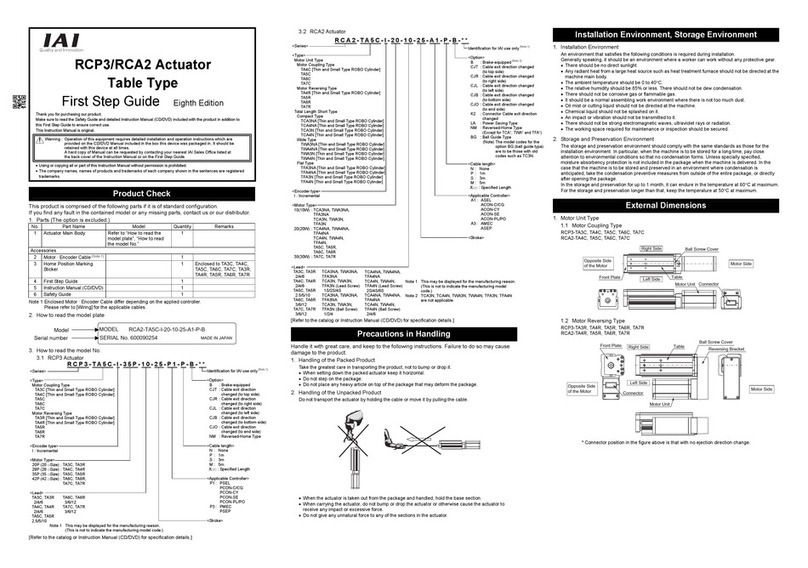

2. How to read the model plate

3. How to read the model No.

Note 1 Identification for IAI use only : It may be displayed for IAI use. It is not a code to show the model type.

Caution in Handling

1. Handling of the Packed Product

Especially in the transportation and handling do not damage or drop as much as possible.

• An operator should never attempt to carry a heavy package on their own.

• If the shipping box is to be left standing, it should be in a horizontal position.

• Do not step or sit on the package.

• Do not put any load that may cause a deformation or breakage of the package.

2. Handling in Unpacked Condition

[RA4R, RA6R, RA7R, RA8R, RA10R]

Do not carry an actuator by motor unit and a track cover area and the cable or attempt to move it by

pulling the cable.

• Hold the body base when transporting the actuator out the package.

• Do not hit or drop the product while carrying. Especially, pay attention to the side cover.

• Do not give any excessive force to any of the sections in the actuator.

• When transporting an actuator, check the weight and the center of gravity of the actuator in

instruction manual before lifting up on a crane. Pay attention to the center point of gravity as it

differs for each model.

Installation and Storage • Preservation Environment

1. Installation Environment

Do not use this product in the following environment.

In general, the installation environment should be one in which an operator can work without protective

gear.

Also make sure to keep enough work space necessary for maintenance.

• Location exposed to radiant heat from a huge heat source such as the heat treatment

• Location where the surrounding air temperature exceeds the range of 0 to 40°C

• Location where condensation occurs due to abrupt temperature changes

• Location where relative humidity exceeds 85%RH

• Location exposed to direct sunlight

• Location exposed to corrosive gases or combustible gases

• Location exposed to significant amount of dust, salt or iron powder (outside of ordinary assembly

plant)

• Location where water, and oil (includes oil mist and cutting fluid) or chemical is splashed

• Location where the product main body receives vibration or hit impact

• Location where the altitude of 2,000m or more

When using the product in any of the locations specified below, provide a sufficient shield.

• Place subject to electrostatic noise

• Location where exposed to the influence of strong electric or magnetic field

• Location where exposed to the influence of ultraviolet or radiant rays

2. Storage • Preservation Environment

• The storage and preservation environment should comply with the same standards as those for

the installation environment.

• In particular, when the machine is to be stored for a long time, pay close attention to

environmental conditions so that no dew condensation forms. Unless specially specified,

moisture absorbency protection is not included in the package when the machine is delivered.

• In the case that the machine is to be stored and preserved in an environment where dew

condensation is anticipated, take the condensation preventive measures from outside of the

entire package, or directly after opening the package.

• For storage and preservation temperature, the machine withstands temperatures up to 60°C for

a short time, but in the case of the storage and preservation period of 1 month or more, control

the temperature to 50°C or less. Storage and preservation should be performed in the horizontal

condition. In the case it is stored in the packaged condition, follow the posture instruction if any

displayed on the package.

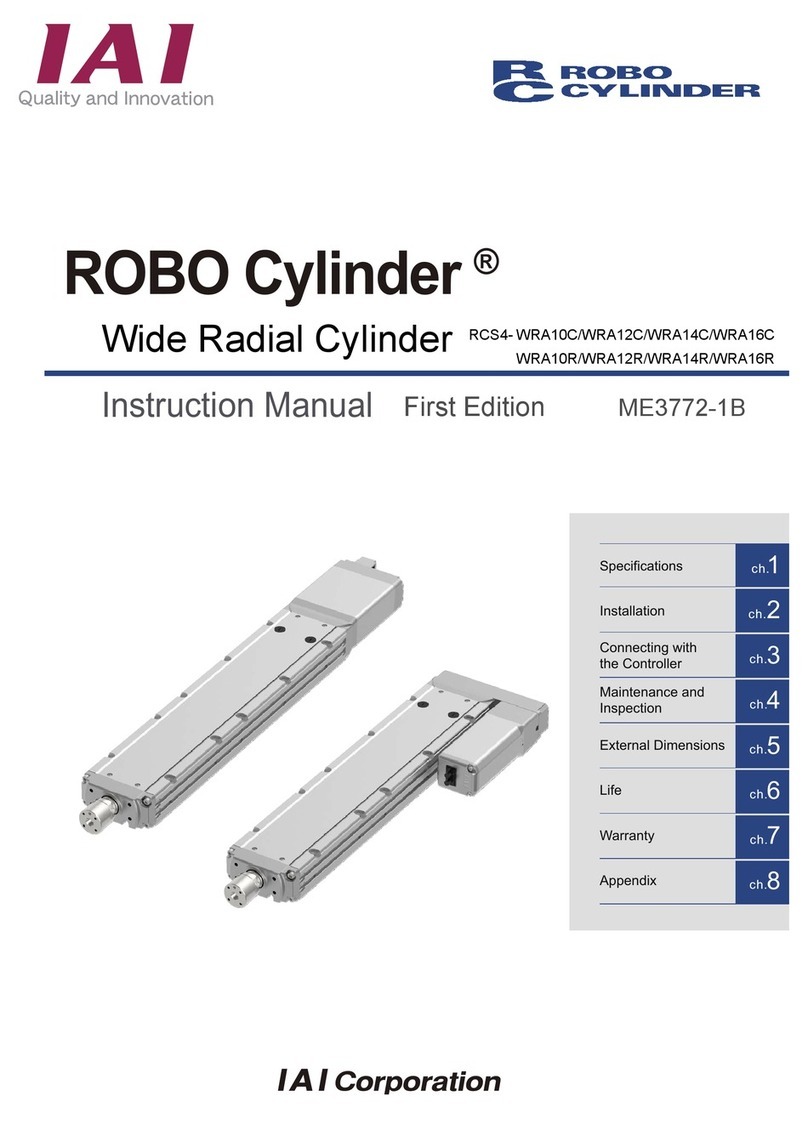

Names of the Parts

1. RA4R

Stroke [mm]

Model Track Cover 1) Track Cover 2)

RA4R 115 to 265 315 to 415

2. RA6R, RA7R

(Note) The profile of the track cover differs depending on the stroke.

Stroke [mm]

Type Track Cover 1) Track Cover 2)

RA6R 115 to 265 315 to 415

RA7R 120 to 270 320 to 520

3. RA8R

(Note) The profile of the track cover differs depending on the stroke.

Stroke [mm]

Type Track Cover 1) Track Cover 2)

RA8R 100 to 250 300 to 500

4. RA10R

(Note) The profile of the track cover differs depending on the stroke.

Stroke [mm]

Type Track Cover 1) Track Cover 2)

RA10R 100 to 200 250 to 500

Warning : Operation of this equipment requires detailed installation and operation instructions which are

provided on the DVD Manual included in the box this device was packaged in. It should be

retained with this device at all times.

A hardcopy of the Manual can be requested by contacting your nearest IAI Sales Office listed

at the back cover of the Instruction Manual or on the First Step Guide.

Model

Serial number

MODEL RCS3-RA6R-I-50-1.5-115-T2-P-LCT

SERIAL No. A00090266 MADE IN JAPAN

RCS3-RA6R- I-50-1.5-115-T2-P-LCT-B-**

Series

<Type>

Motor Reversing Type

RA4R, RA6R

RA7R, RA8R

RA10R, RA15R

RA20R

<Encoder Type>

I : Incremental

A : Absolute

<Motor Type>

30 : 30W 50 : 50W

100 : 100W 200 : 200W

300 : 300W 3300 : 3300W

3000 : 3000W

<Lead>

RA4R : 2.5 RA6R :

1.5

RA7R : 2 RA8R : 2.5

RA10R : 2.5

RA15R (equipped with loadcell): 3.6

RA20R (equipped with loadcell): 4.0

RA15R

(conveyor type (with no loadcell equipped)): 7.2

RA20R

(conveyor type (with no loadcell equipped)): 10

<Stroke>

[Refer to 1.2 Specifications in

Instruction Manual]

Identification for IAI use only (Note 1)

<Option>

B : Brake FL:Flange Bracket

FT : Foot Bracket

ML : Motor Left Reversed (Standard)

MR : Motor Right Reversed

MT : Motor Top Reversed

(RA15R, RA20R)

CJT : Cable Eject Direction Changed (Top)

CJO : Cable Eject Direction Changed

(Outside)

CJB : Cable Eject Direction Changed

(Bottom)

CJR : Cable exit direction changed (Right)

(RA15R, RA20R)

CJL : Cable exit direction changed (Left)

(RA15R, RA20R)

CE : Applicable CE (RA4R)

With Loadcell (with Cable Track for Wiring)

When no indication of LCT in RA15R or RA20R

(conveyor type (with no loadcell equipped))

<Cable Length>

N : No Cable P : 1m

S : 3m M : 5m

X□□ : Specified Length

R□□ : Robot Cable

<Controller>

T2 : SCON-CB/CGB

T3 : With loadcell

RA15R

SCON-CGB-3300□F

RA20R

SCON-CGB-3000□F

Conveyor Type (with no loadcell

equipped)

RA15R

SCON-CGB-3300□

RA20R

SCON-CGB-3000□

Loadcell Loadcell Unit Track Cover 2)

Motor Unit

Cable Track

Rod

Front Bracket

Actuator Cable

Motor SideOpposite side

Frame Cover

Reversing

Bracket

Right Side

Left Side

Pulley Cover

Loadcell Cover

Tapped Hole for

Ground Cable Connection

Base

Track Cover 1)

Loadcell Loadcell Unit

Motor Unit

Cable Track

Rod

Front Bracket

Actuator Cable

Motor SideOpposite Side

Frame Cover

Reversing

Bracket

Grease Supply on the

Ball Screw and Guide

Right Side

Left Side

Pulley Cover

Loadcell Cover

Tapped Hole for

Ground Cable Connection

Base

Track Cover 2)

Track Cover 1)

Loadcell Loadcell Unit

Motor Unit

Cable Track

Rod

Front Bracket

Actuator Cable

Motor Side

Opposite Side

Frame Cover Reversing

Bracket

Grease Supply

on the Ball Screw

Right Side

Left Side

Pulley Cover

Loadcell Cover

Tapped Hole for

Ground Cable Connection

Base

Grease Supply

on the Guide

Track Cover 2)

Track Cover 1)

Pulley Cover

Reversing Bracket

Right Side

Left Side

Loadcell

Base

Rod

Loadcell Cover

Loadcell Unit

Front Bracket

Frame Cover

Cable Track Track Cover 2)

Track Cover 1)

Motor Unit

Actuator Cable

Opposite Side Motor Side