RCP2 (CR) (W) /RCS2 Actuator

Gripper Type

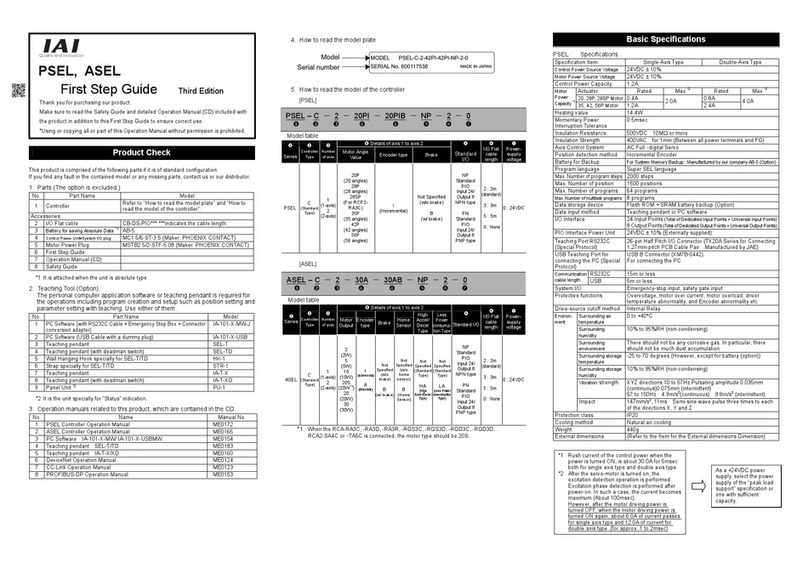

First Step Guide Third Edition

Thank you for purchasing our product.

Make sure to read the Safety Guide and detailed Instruction Manual (DVD) included with the product in addition to this First

Step Guide to ensure correct use.

This Instruction Manual is original.

•Using or copying all or part of this Instruction Manual without permission is prohibited.

•The company names, names of products and trademarks of each company shown in the sentences are registered

trademarks.

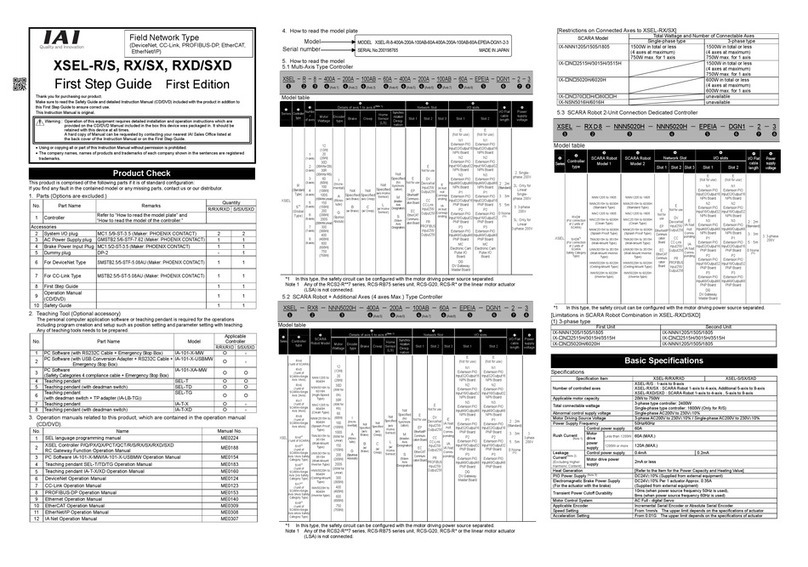

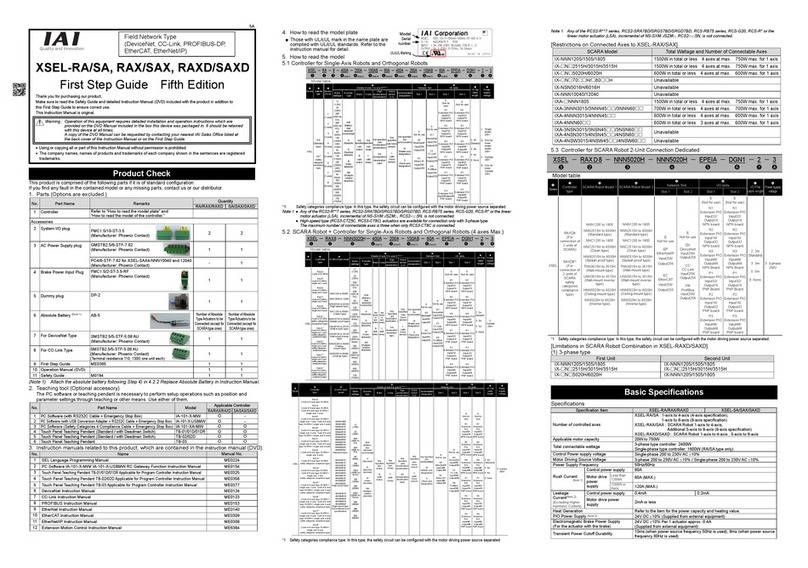

Product Check

This product is comprised of the following parts if it is of standard configuration.

If you find any fault in the contained model or any missing parts, contact us or our distributor.

1. Parts (The option is excluded.)

No. Part Name Model Remarks

1 Actuator Main Body [Refer to “2.How to read the model plate”,

“3.How to read the model.”]

Accessories

2 Motor •Encoder Cable*1

3 First Step Guide

4 Instruction Manual

(DVD)

5 Safety Guide

*1 Please refer to the wiring layout for the enclosed motor cable and encoder cable.

2. How to read the model plate

3. How to read the model

3.1 RCP2 Type

3.2 RCS2 Type

Precautions in Handling

1. Handling of the Packed Product

Unless otherwise specified, the actuator is shipped with each axis packaged separately.

•Do not damage or drop. The package is not supplied with any special treatment that enables it to resist

an impact caused by a drop or crash.

•If the shipping box is to be left standing, it should be in a horizontal position. Follow the instruction if

there is any for the packaging condition.

•Do not step or sit on the package.

•Do not put any load that may cause a deformation or breakage of the package.

2 Handling of Robot without Package

•Do not carry the actuator by holding the cable, or do not move it by pulling the cable.

•When carrying the actuator, exercise caution not to bump it against nearby objects or structures.

•Do not give any excessive force to any of the sections in the actuator.

Environments for Installation, Storage and Preservation

1. Installation Environment

Please attempt to avoid installing the product to such places as listed below.

It is generally the environment where a worker can work without any protection gear. (Dust-proof Types

are excluded)

Also, make sure to keep enough space necessary for maintenance work.

•Place where exposed to radiant heat from a huge heat source such as heat treatment

•Place where the ambient temperature goes out of the applicable range from 0 to 40°C

•Place where condensation would occur due to sudden temperature change

•Place where the relative humidity exceeds 85% RH

•Place where exposed to the direct sunlight

•Place where corrosive gas or flammable gas exist

•Place where it contains a lot of dust, salt or iron (Outside of an ordinary assembly plant) (The except for

dust the dust-proof specification)

•Place where water, oil (includes oil mist and cutting fluid) or chemical is splashed

•Place where the product main body receives vibration or hit impact

• Place with an altitude of 2,000m or more

Make sure to have a treatment for blocking when using in the following conditions:

•Place where noise is generated by such facts as static electricity

•Place where exposed to the influence of strong electric or magnetic field

•Place where exposed to the influence of ultraviolet or radiant rays

2. Storage and Preservation Environment

•The storage and preservation environment should comply with the same standards as those for the

installation environment. In particular, when the machine is to be stored for a long time, pay close

attention to environmental conditions so that no dew condensation forms.

•Unless specially specified, moisture absorbency protection is not included in the package when the

machine is delivered. In the case that the machine is to be stored and preserved in an environment

where dew condensation is anticipated, take the condensation preventive measures from outside of the

entire package, or directly after opening the package.

•For storage and preservation temperature, the machine withstands temperatures up to 60°C for a short

time, but in the case of the storage and preservation period of 1 month or more, control the temperature

to 50°C or less.

•The product should be settled in the horizontal orientation while in storage and reservation. In the case

it is stored in the packaged condition, follow the posture instruction if any displayed on the package.

Names of the Parts

1. Thin and Small Two-finger Slide Type (Standard specification) RCP2-GRSS

2. Thin and Small Two-finger Slide Type (Cleanroom specification) RCP2CR-GRSS

3. Thin and Small Two-finger Slide Type (Dust-proof specification) RCP2W-GRSS

4. Thin and Small Two-finger Lever Type (Standard specification) RCP2-GRLS

Model

Serial numbe

Warning : Operation of this equipment requires detailed installation and operation instructions which are

provided on the DVD Manual included in the box this device was packaged in. It should be retained

with this device at all times.

A copy of the DVD Manual can be requested by contacting your nearest IAI Sales Office listed at

the back cover of the Instruction Manual or on the First Step Guide.

RCP2-GRSS-I-20P-30-8-P1-S-NM

<Series>

RCP2 : Standard Specification

RCP2CR : Clean-Room Specification

RCP2W : Dust-Proof Specification

<Type>

GRSS : Thin and Small Two-finger

Slide Type

GRLS : Thin and Small Two-finger

Lever Type

GRS : Small Two-finger Slide Type

GRM : Medium Two-finger Slide Type

GRHM : Medium Two-finger High-grip-force

Slide Type

GRHB : Large Two-finger High-grip-force

Slide Type

GRST : Small Two-finger Long-stroke Type

GR3SS : Three-finger Slide Type,

Body Width 62mm

GR3SM : Three-finger Slide Type,

Body Width 80mm

GR3LS : Three-finger Lever Type,

Body Width 62mm

GR3LM : Three-finger Lever Type,

Body Width 80mm

<Encoder Type>

I : Incremental

<Motor Type>

20P : Pulse Motor 20 □Size 35P : Pulse Motor 35 □Size

28P : Pulse Motor 28 □Size 42P : Pulse Motor 42 □Size

<Gear Ratio>

1 : 1/1(GRST) 30 : 1/30

2 : 1/2(GRST) 2 : Feed Screw Lead 2(GRHM, GRHB)

<Option>

NM : Reversed Home Specification

FB : Flange Bracket

SB : Shaft Bracket

A0 : Cable Oriented on Bottom

A1 : Cable Oriented on Side

CJT : Cable Exit direction changed

(to top side)

CJR : Cable Exit direction changed

(to right side)

CJL : Cable Exit direction changed

(to left side)

CJB : Cable Exit direction changed

(to bottom side)

VL : L-Shaped type vacuum joint

<Cable Length>

N : None

P : 1m

S : 3m

M : 5m

X□□ : Specified Length

(Example: X07=7m)

R□□ : Robot Cable

(Example: R05=5m)

<Applicable Controller>

P1 : PCON, RPCON, PSEL

P3 : PCON-CA, PMEC

PSEP, MSEP

<Stroke>

8 : 8mm (4mm per side)

10 : 10mm (5mm per side)

14 : 14mm (7mm per side)

32 : 32mm (16mm per side)

40 : 40mm (20mm per side)

60 : 60mm (30mm per side)

80 : 80mm (40mm per side)

100 : 100mm (50mm per side)

19 : 19 degrees

180 : 180 degrees (90 degrees per side)

[Refer to the Catalog or Instruction Manual (DVD) for

specification details.]

RCS2-GR8-I-60-5-20-T1-S-CE

<Option>

CE : CE Marking

<Cable Length>

N : None

P : 1m

S : 3m

M : 5m

X□□ : Specified Length

(Example: X07=7m)

R□□ : Robot Cable

(Example: R05=5m)

<Applicable Controller>

T1 : XSEL-J/K T2 : SCON

SSEL

XSEL-P/Q

<Series>

<Type>

GR8

<Encoder Type>

I : Incremental

<Motor Type>

60 : Servo-Motor 60W

<Gear Ratio>

5 : 1/5

<Stroke>

20 : 20mm (10mm per side) 100 : 100mm (50mm per side)

40 : 40mm (20mm per side) 120 : 120mm (60mm per side)

60 : 60mm (30mm per side) 200 : 200mm (100mm per side)

80 : 80mm (40mm per side)

[Refer to the Catalog o

Instruction Manual (DVD) for specification details.]

MODEL RCP2-GRSS-I-20P-30-8-P1-S-NM

SERIAL No.800061910 MADE IN JAPAN

Actuator Cable

Left Side

Motor Cover

Frame

Finger Guide

Finger

Open/Close

Screw

Finger

Front

Right Side

Rear

Motor Cover Lid

Vacuum Joint

Actuator Cable

Left Side

Motor Cover

Frame

Finger

Finger

Front

Right Side

Rear

Motor Cover Lid

Actuator Cable

Left Side

Motor Cover

Frame

Finger

Finger

Front

Right Side

Rear

Motor Cover Lid

Lever L

Lever R

Actuator Cable

Left Side

Motor Cover

Frame

Open/Close

Screw

Front

Right Side

Rear