3.6 Communicating with the Master Station......................................................................................93

3.6.1 Operation Modes and Corresponding PLC I/O Areas........................................................93

3.6.2 Remote I/O Mode (Number of Occupied Bytes: 2) ............................................................95

3.6.3 Position/Simplified Direct Value Mode (Number of Occupied Bytes: 8).............................99

3.6.4 Half Direct Value Mode (Number of Occupied Bytes: 16)............................................... 104

3.6.5 Full Direct Value Mode (Number of Occupied Bytes: 32) ............................................... 111

3.6.6 Remote I/O Mode 2 (Number of Occupied Bytes: 12) .................................................... 122

3.6.7 I/O Signal Controls and Function .................................................................................... 126

3.7 I/O Signal Timings .................................................................................................................... 143

3.8 Operation.................................................................................................................................. 144

3.9 EtherNet/IP Related Parameters.............................................................................................. 152

3.10 Troubleshooting........................................................................................................................ 157

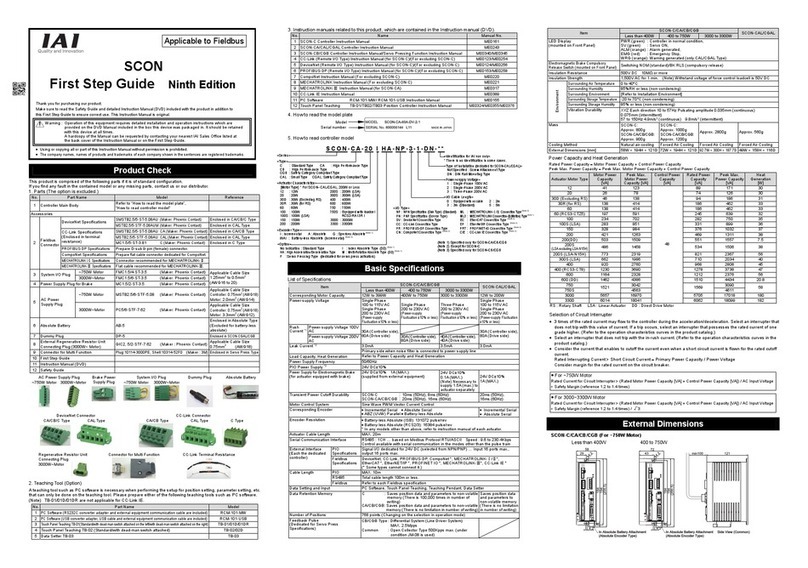

4. SCON-CA .......................................................................................................................................... 158

4.1 Operation Modes and Functions .............................................................................................. 158

4.2 Model Numbers ........................................................................................................................ 162

4.3 EtherNet/IP Interface ................................................................................................................ 163

4.3.1 Names of the Parts.......................................................................................................... 163

4.3.2 Monitor LED Indications .................................................................................................. 164

4.4 Wiring........................................................................................................................................ 165

4.4.1 Connection Diagram........................................................................................................ 165

4.4.2 Connector Pin Layout...................................................................................................... 165

4.5 Setting....................................................................................................................................... 166

4.5.1 Operation Mode Selecting............................................................................................... 166

4.5.2 Setting the Baud Rate ..................................................................................................... 166

4.5.3 Setting the IP Address..................................................................................................... 167

4.5.4 Setting the Subnet Mask ................................................................................................. 167

4.5.5 Setting the Default Gateway............................................................................................ 167

4.6 Communicating with the Master Station................................................................................... 168

4.6.1 Operation Modes and Corresponding PLC I/O Areas..................................................... 168

4.6.2 Remote I/O Mode (Number of Occupied Bytes: 2) ......................................................... 172

4.6.3 Position/Simplified Direct Value Mode (Number of Occupied Bytes: 8).......................... 177

4.6.4 Half Direct Value Mode (Number of Occupied Bytes: 16)............................................... 182

4.6.5 Full Direct Value Mode (Number of Occupied Bytes: 32) ............................................... 189

4.6.6 Remote I/O Mode 2 (Number of Occupied Bytes: 12) .................................................... 200

4.6.7 Position/Simplified Direct Value Mode2 (Number of Occupied Bytes: 8)...................... 204

4.6.8 Half Direct Value Mode 2 (Number of Occupied Bytes: 16)............................................ 209

4.6.9 Remote I/O Mode 3 (Number of Occupied Bytes: 12) .................................................... 216

4.6.10 Half Direct Value Mode 3 (Number of Occupied Bytes: 16)............................................ 220

4.6.11 I/O Signal Controls and Function .................................................................................... 227

4.7 I/O Signal Timings .................................................................................................................... 245

4.8 Operation.................................................................................................................................. 246

4.9 EtherNet/IP Related Parameters.............................................................................................. 254

4.10 Troubleshooting........................................................................................................................ 261

5. Appendix............................................................................................................................................ 262

5.1 Example of Connection Settings with Omron’s Master ............................................................ 262

5.1.1 Connection Example ....................................................................................................... 262

5.1.2 Setting the Controller....................................................................................................... 262

5.1.3 Setting the PLC (1) [CX-Programmer]............................................................................. 263

5.1.4 Setting the PLC (2) [Network Configurator]..................................................................... 265

5.1.5 Checking the I/O Data on the PLC.................................................................................. 275