Contents

Safety Guide ···················································································· Intro-1

Precautions for Handling ···································································· Intro-9

International Standard Compliance ······················································· Intro-12

Precautions for Handling Wireless Operation ·········································· Intro-13

Precautions for Axis Operation with Wireless Connection ·························· Intro-16

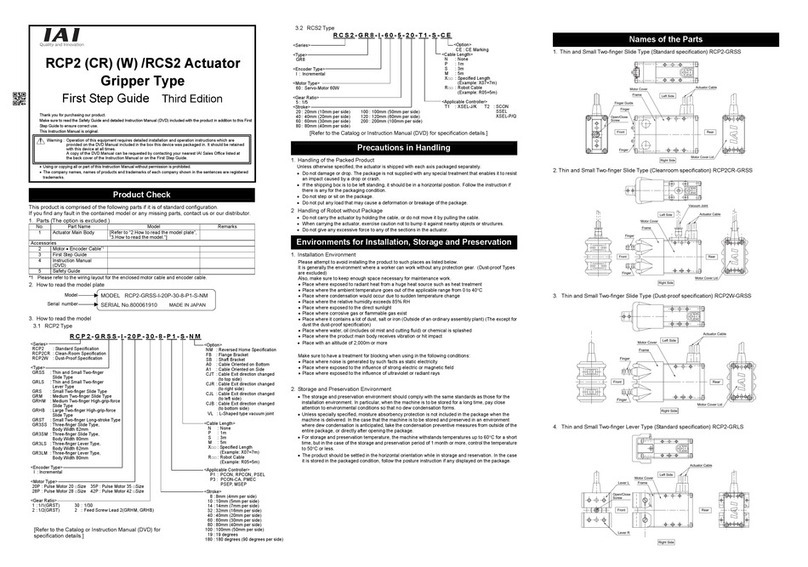

Part Names ····················································································· Intro-17

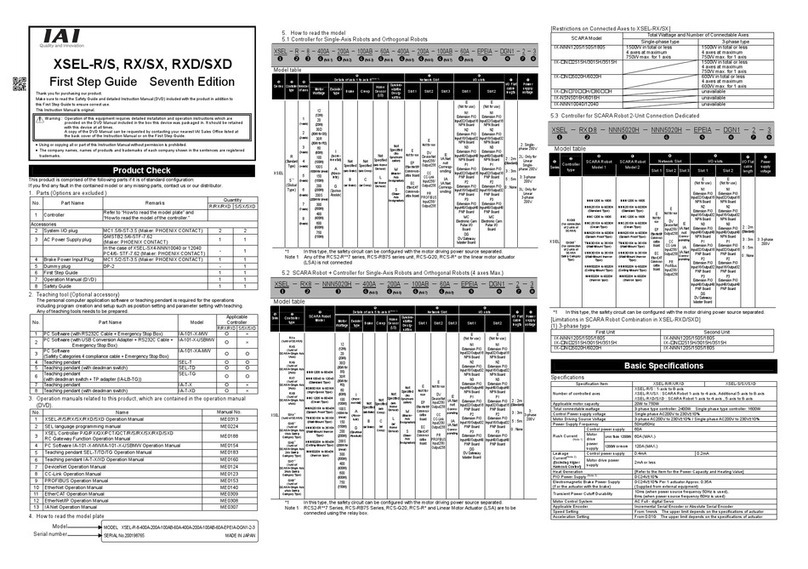

Chapter 1 Specifications

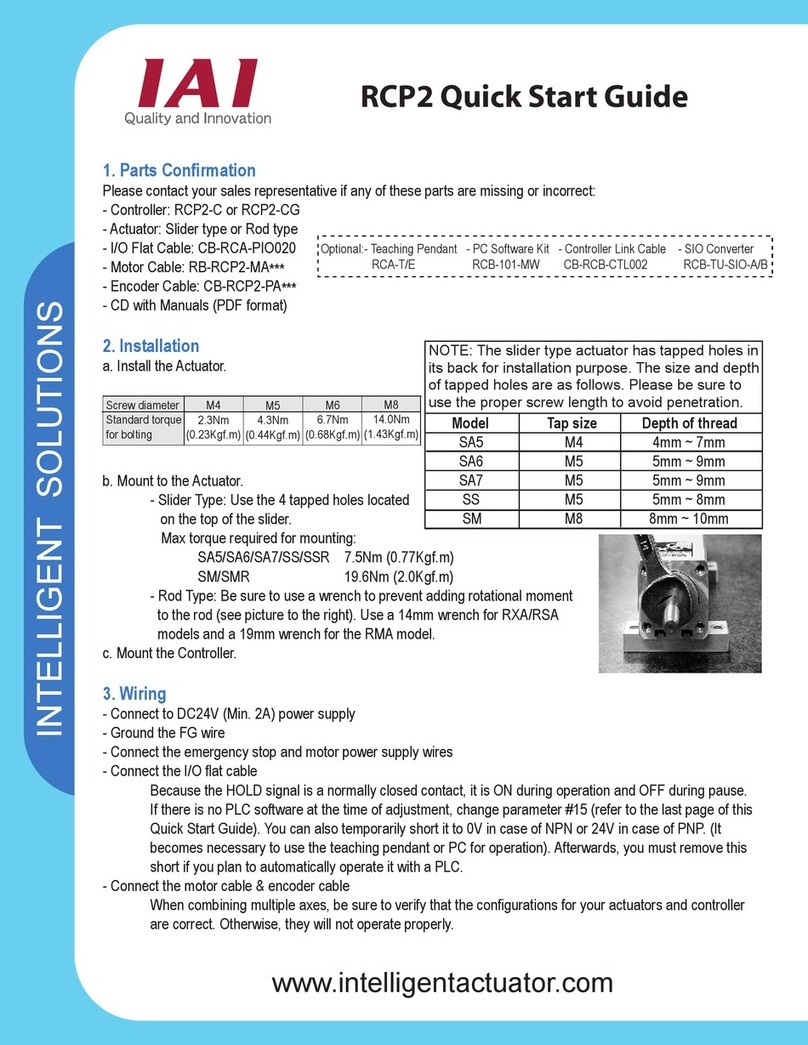

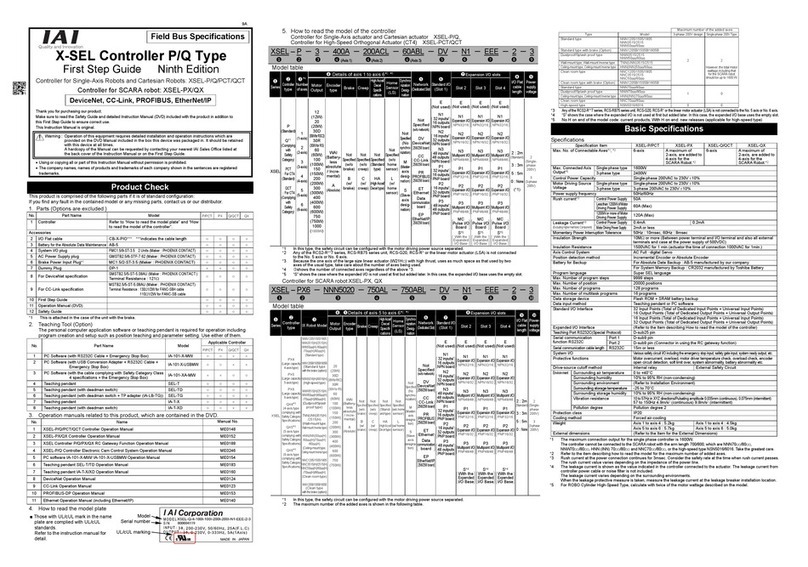

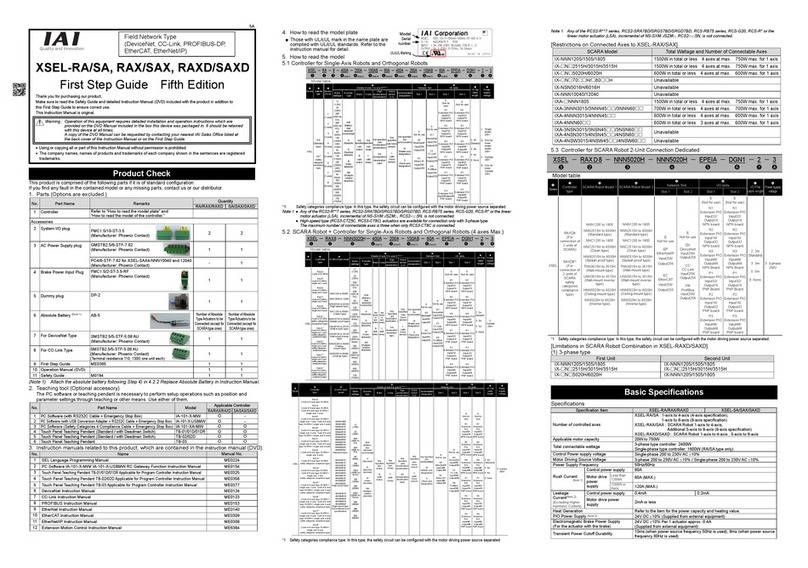

1.1 Checking the product ································································ 1-1

Components ·································································································· 1-1

How to read the model nameplate ······································································ 1-2

How to read the model number ·········································································· 1-2

Product list ···································································································· 1-3

1.2 Mechanical specifications ·························································· 1-4

Rod type RP4 ································································································ 1-4

Rod type GS4 ································································································ 1-7

Rod type GD4 ································································································ 1-11

Table type TC4 ······························································································· 1-15

Table type TW4 ······························································································ 1-20

Duty ratio ······································································································ 1-25

1.3 Options ·················································································· 1-26

RCON-EC connection specification (model: ACR) ················································· 1-26

With brake (model: B) ······················································································ 1-26

Home reverse specification (model: NM) ····························································· 1-26

PNP specification (model: PN) ··········································································· 1-26

Battery-less absolute encoder specification (model: WA) ········································ 1-26

Wireless communication specification (model: WL) ················································ 1-26

Wireless axis operation specification (model: WL2) ··············································· 1-27

2-circuit power supply type (Model: TMD2) ·························································· 1-27

S4 guide mounting direction / TC4 table mounting direction (Model: GT2, GT3, GT4) ··· 1-28

1.4 Accessories ············································································ 1-29

Power / I/O cable ···························································································· 1-29

Power I/O connector ························································································ 1-30

Chapter 2 Installation

2.1 Precautions for transportation ····················································· 2-1

2.2 Installation and storage/preservation environment ··························· 2-4

Installation environment ······················································································· 2-4

Storage/preservation environment ·········································································· 2-5

2.3 How to install rod type RP ··································································· 2-6

Installation surface ·························································································· 2-6

Fixing bolts ···································································································· 2-6

Mounting orientation ························································································ 2-7

Body mounting ······························································································· 2-8

Rotation stop mounting ···················································································· 2-10

2.4 How to install rod type GS / table type GD ··············································· 2-12

Installation surface ·························································································· 2-12

Fixing bolts ···································································································· 2-12

Mounting orientation ························································································ 2-13

Body mounting ······························································································· 2-14

2.5 How to install table type TC / table type TW ············································· 2-15