4.2.3 Connecting an Emergency Stop Circuit, Etc................................................................. 46

5. Explanation of Operating Functions..................................................................................................... 47

5.1 Description of Position Table ..................................................................................................... 48

5.1.1 Relationship of Push Force at Standstill and Current-Limiting Value ........................... 52

5.2 Data Set in the Numerical Specification Mode .......................................................................... 54

5.3 Explanation of Functions ........................................................................................................... 54

5.3.1 Control Signals and Control Data ................................................................................. 56

5.3.2 Timings after Power On ................................................................................................ 62

5.3.3 Home Return Operation................................................................................................ 64

5.3.4 Positioning Operation.................................................................................................... 66

5.3.5 Push & Hold Operation ................................................................................................. 70

5.3.6 Pause............................................................................................................................ 74

5.3.7 Speed Change during Movement ................................................................................. 75

5.3.8 Operation at Different Acceleration and Deceleration .................................................. 77

5.3.9 Zone Signal................................................................................................................... 78

5.3.10 Pitch Feed by Incremental Specification....................................................................... 79

5.3.11 Power-Saving Mode at Standby Positions.................................................................... 83

6. Parameter Settings .............................................................................................................................. 84

6.1 Parameter Table ........................................................................................................................ 84

6.2 Detailed Explanation of Parameters .......................................................................................... 85

6.2.1 Parameters Relating to the Actuator Stroke Range...................................................... 85

6.2.2 Parameters Relating to the Actuator Operating Characteristics................................... 87

6.2.3 Parameters Relating to the External Interface.............................................................. 91

6.2.4 Servo Gain Adjustment ................................................................................................. 93

7. Troubleshooting ................................................................................................................................... 95

7.1 Action to Be Taken upon Occurrence of Problem...................................................................... 95

7.2 Alarm Level Classification.......................................................................................................... 96

7.2.1 How to Reset Alarms .................................................................................................... 96

7.3 Alarm Description and Cause/Action......................................................................................... 97

7.4 Messages Displayed during Operation Using the Teaching Pendant or PC Software............ 102

7.5 Specific Problems .................................................................................................................... 104

8. Maintenance and Inspection .............................................................................................................. 106

8.1 Inspection Items and Schedule ............................................................................................... 106

8.2 Visual Inspection of Appearance ............................................................................................. 106

8.3 Cleaning................................................................................................................................... 106

8.4 Internal Check (Slider Type) .................................................................................................... 107

8.5 Internal Cleaning (Slider Type) ................................................................................................ 108

8.6 Greasing the Guide (Slider Type) ............................................................................................ 108

8.7 Greasing the Ball Screw (Slider Type)..................................................................................... 110

8.8 Greasing the Rod Slide Surface .............................................................................................. 111

8.9 Motor Replacement Procedure................................................................................................ 112

9. Operation Examples .......................................................................................................................... 114

10. Appendix ........................................................................................................................................... 115

.......................................................................................................................... 115

..........................................................................................................................115

..........................................................................................................................116

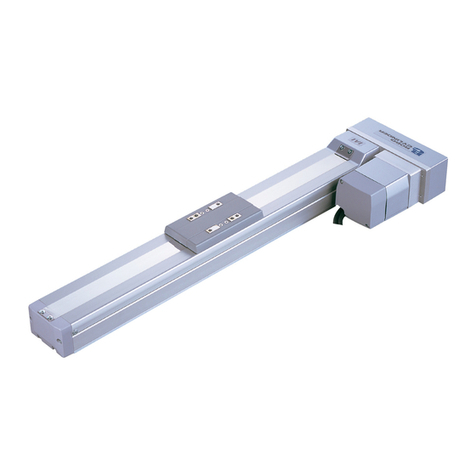

10.1 External Dimensions

10.1.1 ERC2-SA6C

10.1.2 ERC2-SA7C