Warning

Use this vessel only in hydronic systems. The installer must comply with all plumbing

codes. Do not operate above the temperature or pressure specified on the rating plate.

Failure to comply may result in personal injury, property damage, or death.

Warning

Do not use in potable water systems.

This buffer tank is designed for use with geothermal heat pumps/ chillers/ low mass boilers to reduce

short cycling. They are used primarily in systems operating below the design load condition, or in

systems having several low BTU cooling or heating loads calling at different times. This can cause

the appliances to short cycle, resulting in reduced operating efficiency and shorter equipment life.

This tank is built with four connections: two connections for piping to the heating or cooling source

(on the left side), and two connections for piping to the distribution system (on top and on the right

side). The tank can serve as both a thermal buffer and a hydraulic separator to hydraulically

decouple the heating or cooling source from the distribution system.

The buffer tank is constructed with 444 stainless steel, 316 stainless steel connection fittings, 2"

thick foam insulation and a powder coated galvanized steel jacket. A 3/8" ID thermal well is located

mid-tank. Thermistors can be inserted 3" into the well. Alternatively, Honeywell L4006A Controls

can also be used.

Piping connections to both the heating or cooling source and the distribution system are 1 ½" NPT.

The drain is ¾" NPT.

The tank's top fitting should be piped to the distribution supply line and the air purger and vent, so

that the tank will be self venting, and no additional air vent is needed. Pipe the buffer tank so that the

heating or cooling source is hydraulically decoupled from the distribution system.

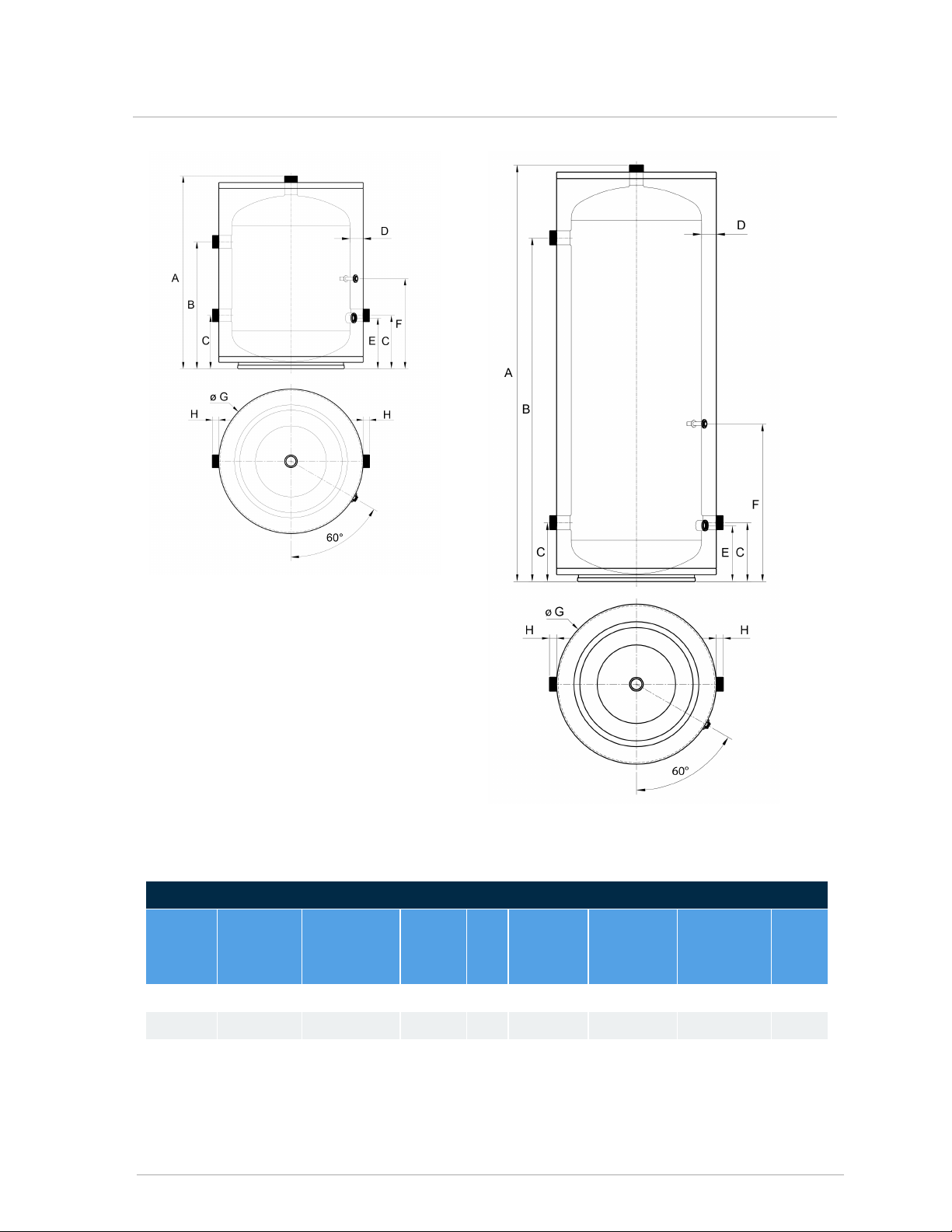

Section: IBTBuffer tanks