Note

Ifconvertingtonaturalgas,ordertheNaturalGasConversionPartskit(P-1200)fromyourauthorized

IBCdistributor.

UsethePropaneGasConversionkitifthefuelsourceatthesiteusespropaneandthemodulatingboilerhas

beensetup(factoryfire-tested)tooperatewithnaturalgas.Checktheratingplateontheboilertoseewhichfuel

sourcetheparticularboilerhasbeensetupwith.

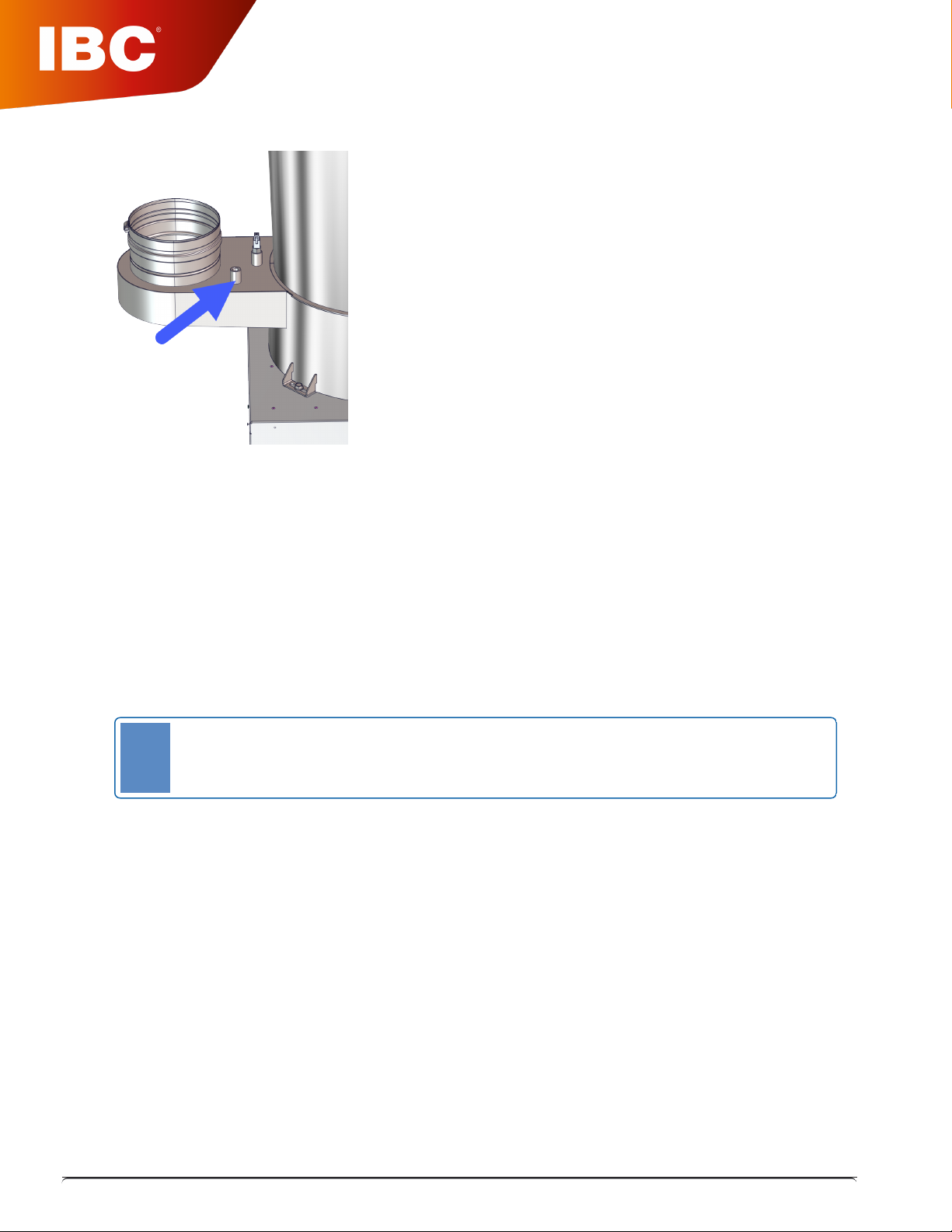

Usingthisconversionkit,aqualifiedtechnicianwillneedto:

1. Performafuelconversion.

2. Performacombustiontest.

3. Fillintheinformationrequiredonthefuelconversionlabels,andaffixthemtotheboilerafterthe

conversioniscompleted.

Warning

Thisconversionkitshallbeinstalledbyaqualifiedserviceagencyinaccordancewiththe

manufacturer’sinstructionsandallapplicablecodesandrequirementsoftheauthorityhaving

jurisdiction.Iftheinformationintheseinstructionsisnotfollowedexactly,afire,anexplosionor

productionofcarbonmonoxidemayresultcausingpropertydamage,personalinjuryorlossoflife.

Thequalifiedserviceagencyisresponsiblefortheproperinstallationofthiskit.Theinstallationisnot

properandcompleteuntiltheoperationoftheconvertedapplianceischeckedasspecifiedinthe

manufacturer’sinstructionssuppliedwiththekit.

IncludedwiththeConversionKit:

Fuel Conversion Kit, NG to LP - EX 700

Part # Description Quantity

150-001 O-Ring,126Nitrile 1

150-025 Wshr,Flat,Zn,1/4 4

150-159 M5FlatWasher 4

150-329 M8x14HexBolt 6

150-339 M8FlatWasher 6

150-354 M5x25HexBolt 4

150-373 HexBolt1/4-20x1.25L 4

150-376 O-ring 1

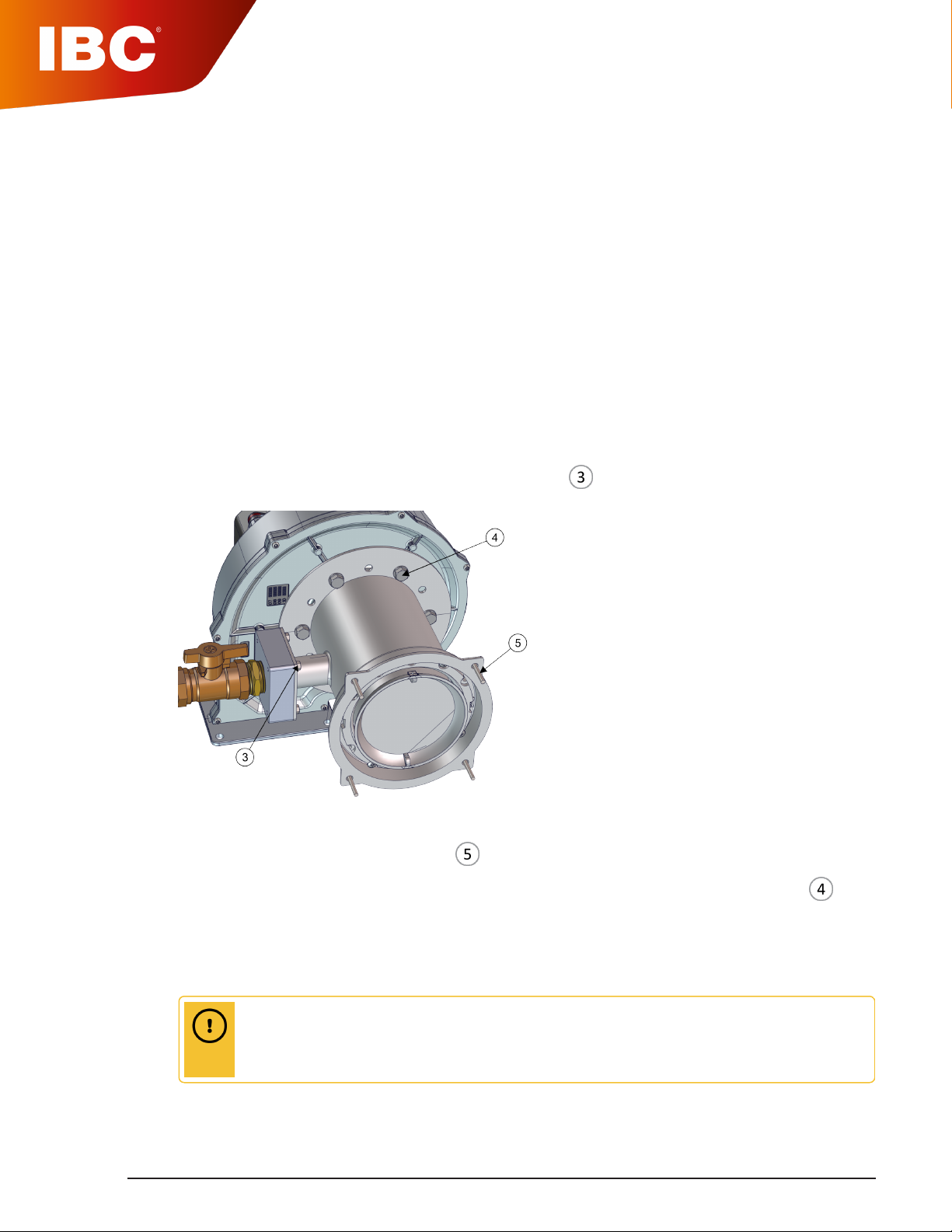

180-255 Mixer,PGT700,LP 1

080-284 Ratingplateoverlay 1

080-244 Installeridentifierlabel 1

080-107 Gasvalveconversionlabel 1

EX 700 - Fuel Conversion to Propane

(NG to LP) - P-1201