IDW G-Series User manual

Models: Listed on Inside Cover

G-Series Cooler

Instruction Manual

RCM-VisID

Innovative DisplayWorks, Inc.

RCM-VisID

3

G-Series Cooler

Instruction Manual

For Future Reference

• This easy-to-use manual will guide you in getting the best use of your cooler.

• Remember to record the model number and the serial number. This information can be

found on the inside of your cooler.

• Keep your receipt with this manual for future warranty service.

Model #:

Serial #:

Date of Purchase:

RCM-77 Models:

RCM-VisID-N23EB

RCM-VisID-NA34B

Table of Contents

Parts & Identication Lists.........................4-5

Safety Instructions.................................... 6

Installation............................................. 7

Ambient Environment............................. 7

Preparation Prior to Operation .................. 7

Electrical Requirements .......................... 7

Leveling................................................ 8

Beverage Storage.................................... 8

Clamp Installation.................................... 8

Installation & Operation ............................ 9

Rechargeable Battery Instructions ................ 9

Maintenance .........................................10

Graphic Replacement ..............................10

Specications ........................................11

Flammable Refrigerant Warnings ................11

Troubleshooting.....................................12

Circuit Diagrams ....................................13

RCM-VisID

Instruction Manual

Innovative DisplayWorks, Inc.

RCM-VisID

4 5

Innovative DisplayWorks

offi ce 909.447.8254 • fax 909.305.8756 • toll free 877.307.2665 • www.idw.global

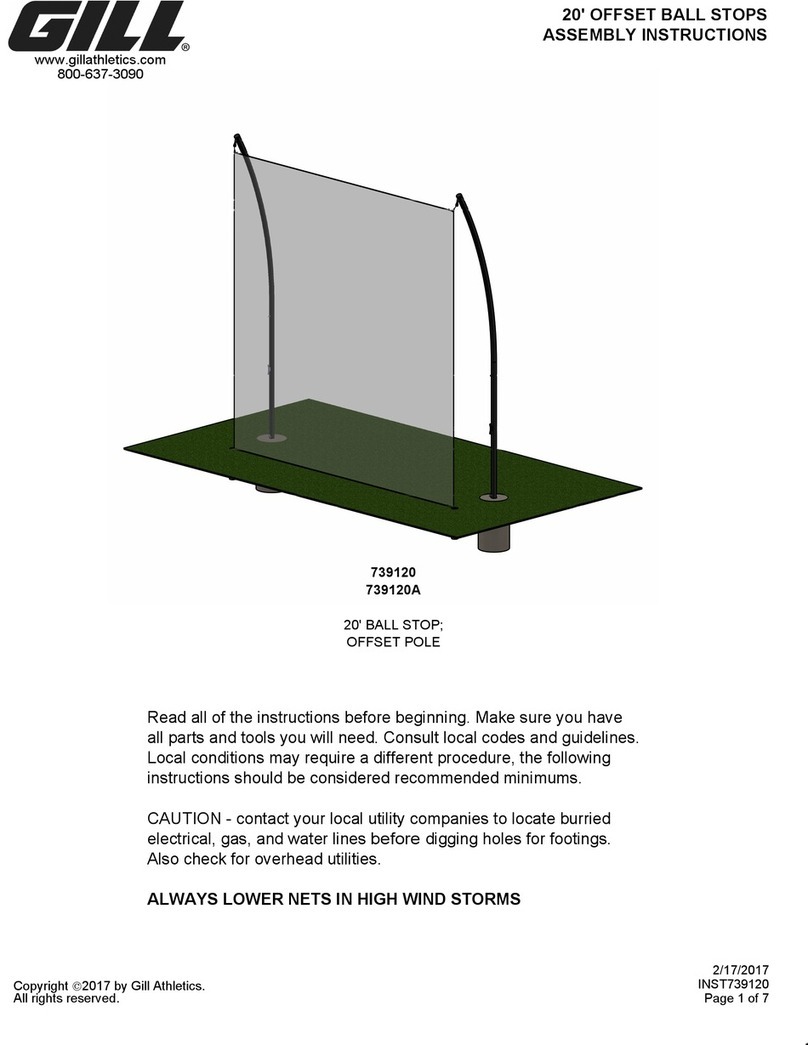

PARTS & IDENTIFICATION

Last Revised: June 29, 2020 5:22 PM

RCM-VisID

1

3

2

4

2

5

8

9

6

11

14

15

16

17

18

20

13

30

31

33

34

35

37

38

32

19

7

10

21

22

36

23

24

25

26

27

28

29

12

1. Cooler Cabinet

2. Power Cord Holder (2)

3. Transformer

4. Transformer Box

5. Grill Bracket

6. Outlet Pipe

7. Drip Pan Cover

8. Drip Pan

9. Compressor

10. Compressor Base

11. Thermostat

12. Condenser

13. Caster (2)

14. Base Support

15. Shell Base Support

16. Caster with Lock (2)

17. Condenser Fan Grill

18. Condenser Fan Supporter

19. Condenser Fan (2)

20. Wire Holder Cover

21. Power Cord Clip

22. Power Cord

23. Fan Connecting Line

24. Ground Line 1

25. Thermostat Connecting Line

26. Ground Line 2

27. Fan Grounding Line

28. Compressor Grounding Line

29. Lid

30. Evaporator Fan Cover (2)

31. Basket

32. Evaporator Baffl e

33. Evaporator Fan Cover

34. Evaporator Fan

35. Evaporator Fan Grill

36. Inner Frame

37. Inner Liner

38. Coolant Box (16)

Innovative DisplayWorks

offi ce 909.447.8254 • fax 909.305.8756 • toll free 877.307.2665 • www.idw.global

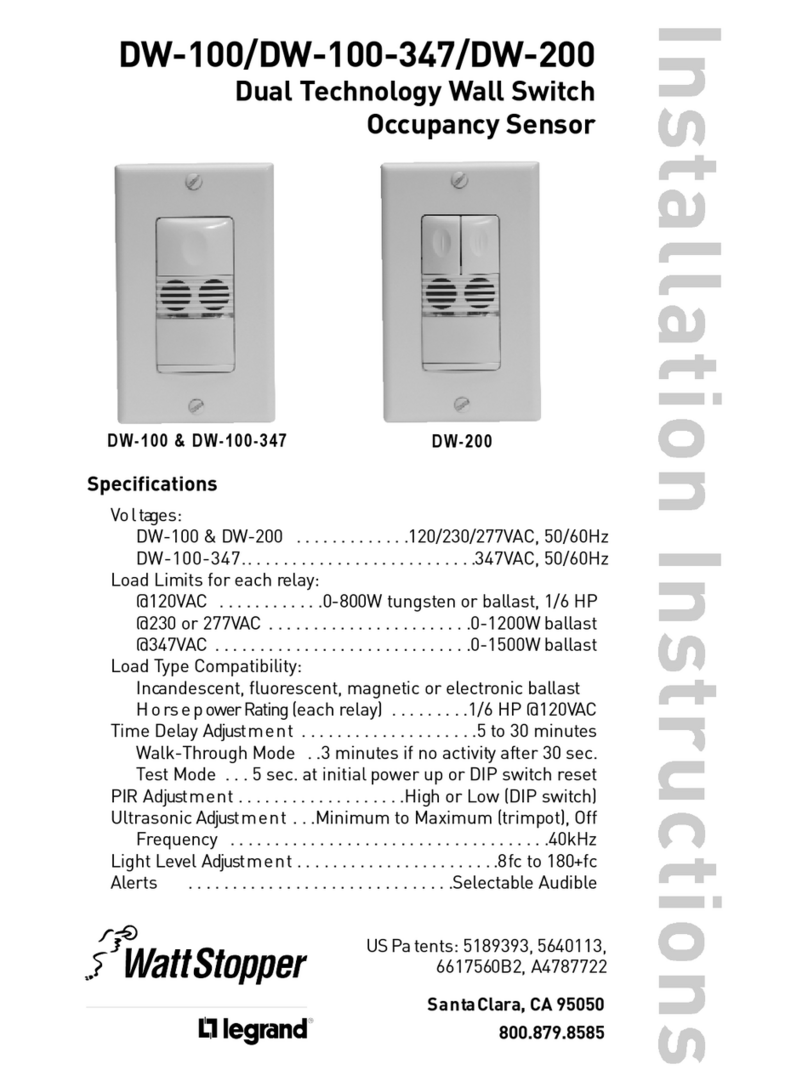

PARTS & IDENTIFICATION

Last Revised: June 29, 2020 5:22 PM

RCM-VisID

1. Cabinet

2. Power Cord Holder (2)

3. Transformer

4. Transformer Box

5. Compressor Room Holder Assembly

6. Outlet Pipe

7. Drip Pan

8. Compressor

9. Base

10. Thermostat

11. Condenser Fan

12. Condenser Fan Supporter

13. Condenser

14. Universal Caster (3)

15. Base Supporter

16. Shell Base Supporter (4)

17. Caster With Lock

18. Wire Holder Cover

19. Cord Clip

20. Power Cord

21. Thermostat Wire

22. Grounded Line

23. Fan Grounded Line

24. Compressor Grounded Line

25. Lid

26. Clip (2)

27. Basket

28. Evaporator Fan Battle

29. Evaporator Fan Cover

30. Evaporator Fan

31. Evaporator Fan Grill

32. Rim

33. Ice Packs (8)

34. Inner Liner

RCM-VisID-N23EB RCM-VisID-NA34B

Instruction Manual

Innovative DisplayWorks, Inc.

RCM-VisID

6 7

INSTALLATION

Installation of the cooler must be done according to applicable local codes or equivalent.

Ambient Environment

• Place cooler on an even surface to reduce

vibration and noise.

• To transport, do not tilt the cooler beyond

a 45 degree angle.

• Do not place cooler in direct sunlight or

near any heat sources.

• Do not place cooler in environment

temperatures that exceed 80°F.

• Do not place cooler in below normal

temperatures.

• Do not place cooler in extreme humid

environments, this may cause components

to rust.

• Do not place cooler near constant running

or splattering water, this may cause

immediate damage to refrigeration system.

• Must allow at least 4” between rear of

cooler and wall for proper ventilation and

heat dissipation of cooler.

• Do not place furniture or other articles with

sharp edges near the cooler in order to

prevent damage to the glass door.

• This cooler is for indoor use.

• Place unit in it’s nal location, making certain

there is adequate ventilation in the room.

WARNING: Warranty is void if ventilation

is insuf cient.

Preparation Prior to Operation

Electrical Requirements

• Remove all packaging materials before

using cooler. This includes: foam pedestal,

adhesive tape (used to x accessories) and

protective gaskets.

• Inspect cooler for concealed damage.

Immediately le a claim with the freight

carrier if there is damage. IDW is not

responsible for damage incurred during

shipping.

• Cooler must remain unplugged in an

upright position for 1 hour prior to use.

• Clean the interior surface with a soft cloth

and lukewarm water before operation.

• Ensure that drain hose or hoses are

positioned in the pan.

• Remove plug and cord from inside the

lower rear of the cooler.

• The unit should be placed close enough

to the electrical supply so that extension

cords are not used.

• This model operates with a 110-120V/60Hz

power supply. Check the electrical outlet

for proper voltage.

• Dedicate one outlet for the use of the

cooler.

• Do not use an extension cord or any other

multiple connectors as this can lead to

compressor failure.

• If the cord is damaged, it must be replaced.

• For your safety, plug the unit into a

grounded wall outlet. Please check with a

certi ed electrician for details.

WARNING: Do not use extension cords.

WARNING: Compressor warranties are

void if compressor burns out due to low

voltage.

WARNING: Power cord ground pin must

NOT be removed!

1. When using this appliance, always follow the

basic safety precautions:

2. Read the entire User’s Manual before

operating this appliance.

3. Use this appliance only for its intended

purpose as described in this User’s Manual.

4. This cooler must be properly installed in

accordance with the installation instructions

before being used. See grounding

instructions.

5. IDW requires that a dedicated circuit be used

for the unit. Failure to do so voids warranty.

6. Never unplug your cooler by pulling on the

power cord. Always grasp the plug rmly and

pull it straight out from the outlet.

7. Unplug your cooler before cleaning or

making any repairs.

Note: If for any reason this product requires

service, we strongly recommend that a

certi ed technician perform the service.

8. When disconnecting the power source, wait

at least 5 minutes to reconnect the power to

avoid damage to the compressor and the

cooling system.

9. Immediately repair or replace all electrical

cords that have become frayed or otherwise

damaged. Do not use a cord that shows

cracks or abrasion damage along its length,

the plug or the connector end.

10. Do not operate or store your cooler near or

around explosive fumes, gasoline or other

fl ammable vapors and liquids.

11. Do not use fl ammable liquids to clean unit.

12. Setting the temperature control to the 0

position does not remove power to the light

circuit, perimeter heaters, or evaporator fans.

13. The temperature control is factory set for

maximum performance.

14. To avoid damage to the casters, do not

transport the cooler on rough surfaces.

15. The battery may release poisonous gas or

explode if it is burned, broken or if air fl ow is

restricted.

16. Do not remove the battery cover.

SAFETY INSTRUCTIONS

PLEASE SAVE THESE

INSTRUCTIONS!

DANGER!

PROPER DISPOSAL OF THE

REFRIGERATOR

Pre-Caution, Non-Operating Coolers

Should Have:

1. Lid removed.

2. Baskets kept in place in order

to prevent any small child from

climbing inside cooler.

For Proper Disposal of Cooler:

Distributors/retailers need to contact

a quali ed service technician:

1. To recover all refrigerant from

the cooler

2. To remove the compressor

or remove the oil from the

compressor

Then the distributor/retailer can

contact their local metal recycling

center to pick up the remaining

cabinet, shelves, etc. By law, disposal

of hazardous wastes may be subject

to nes and imprisonment under

the provisions of the environmental

regulations. For more information

please visit: http://www.epa.gov/

osw/hazard/index.htm

17. Do not touch the battery after the cooler has

been plugged in to avoid electric shock.

Instruction Manual

Innovative DisplayWorks, Inc.

RCM-VisID

8 9

LEVELING

• Place unit in a well ventilated area.

• WARNING: Warranty is void if ventilation is insuf cient.

• Unit must be leveled for proper operation, this will help prevent condensation.

• The cooler should be leveled front to back and side to side with a level.

INSTALLATION AND OPERATION

• Connect the power source. After 30 minutes of operation, the unit should show signs of

cooling.

• After the empty cooler has been operating for a period of 5 hours, the unit can be loaded

with product.

BEVERAGE STORAGE

• Leave adequate space between beverage cans to allow air

circulation

• This cooler is primarily for storing beverage cans and plastic

bottles. Avoid putting glass containers in this cooler.

• All beverage products should be properly sealed to avoid

leaking into the cooler.

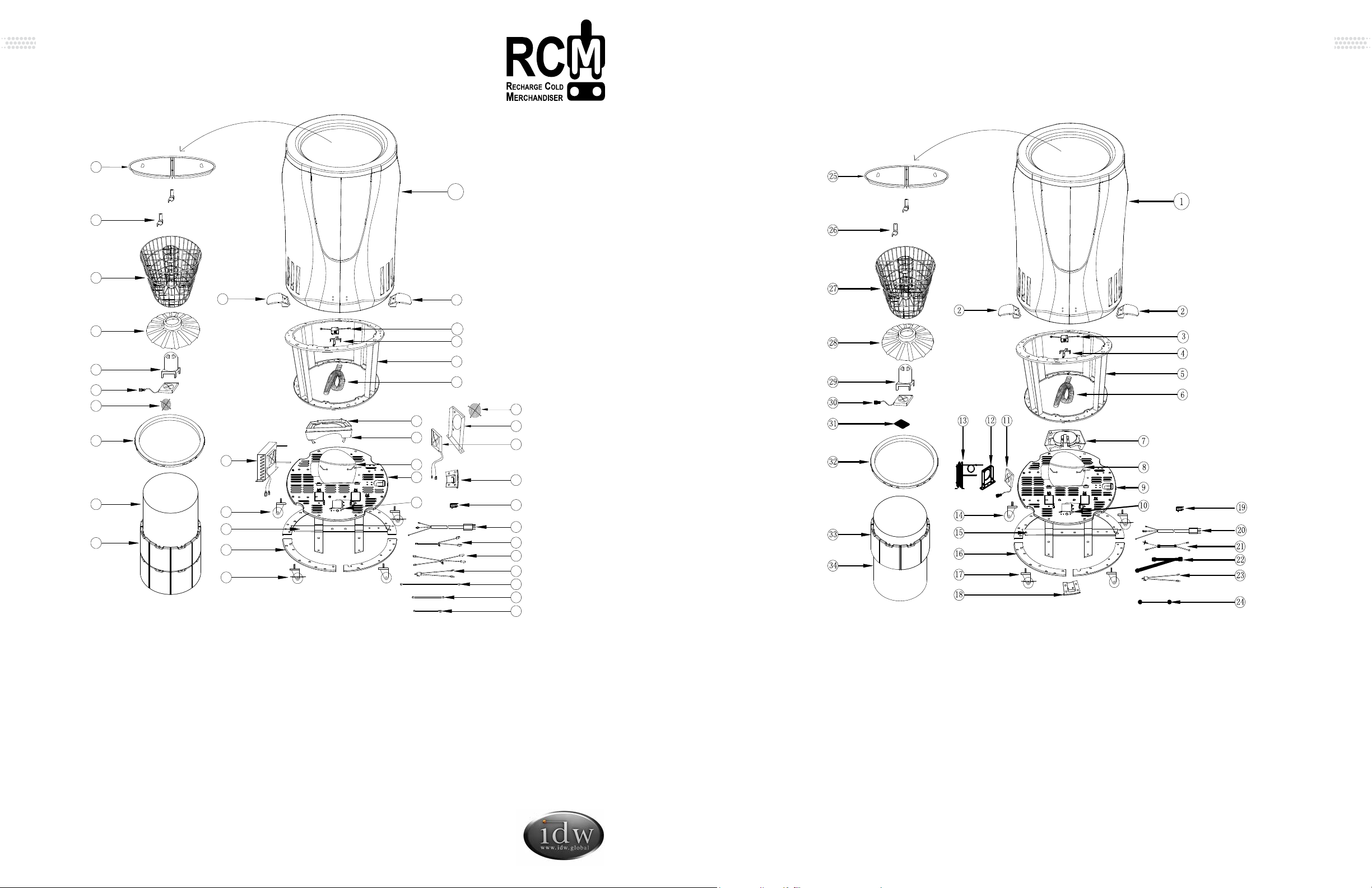

CLAMP INSTALLATION

1. The clamp secures the

lid assembly to the main

body of the cabinet.

Locate the (2) notches on

the interior of the lid.

2. Snap the (2) bolts into the

notches of the lid.

4. Hook the (2) clamps onto the

center bar of the basket.

3. Snap the (2) bolts into the

notches of the lid.

LEVELING

• Place unit in a well ventilated area.

• WARNING: Warranty is void if ventilation is insuf cient.

• Unit must be leveled for proper operation, this will help prevent condensation.

• The cooler should be leveled front to back and side to side with a level.

INSTALLATION AND OPERATION

• Connect the power source. After 30 minutes of operation, the unit should show signs of

cooling.

• After the empty cooler has been operating for a period of 5 hours, the unit can be loaded

with product.

BEVERAGE STORAGE

• Leave adequate space between beverage cans to allow air

circulation

• This cooler is primarily for storing beverage cans and plastic

bottles. Avoid putting glass containers in this cooler.

• All beverage products should be properly sealed to avoid

leaking into the cooler.

CLAMP INSTALLATION

1. The clamp secures the

lid assembly to the main

body of the cabinet.

Locate the (2) notches on

the interior of the lid.

2. Snap the (2) bolts into the

notches of the lid.

4. Hook the (2) clamps onto the

center bar of the basket.

3. Snap the (2) bolts into the

notches of the lid.

INSTALLATION AND OPERATION

1. Connect the empty RCM to a Power Source for 12+ hours.

2. After the empty cooler has been operating for an initial period of 12 hours, the unit can then be

loaded with products*.

3. The cooler can then be unplugged and rolled to any high traf c retail location for up to 12 hours.

After 12 hours the unit must be plugged in again for an additional 12 hours. (The Re-Charge

cycle)

It is important to understand that the Re-Charge Cold Merchandiser (RCM) is designed to operate

differently than typical beverage coolers. Typical coolers circulate the cold the air inside the cabinet

to chill the beverages. The RCM does not follow this principle. The RCM freezes liquid lled coolant

packs within the interior walls of the cabinet. It is important that these coolant packs are completely

frozen to ensure that the beverages will be kept at a cold temperature for the maximum amount

of time while the unit is unplugged and moved to the desired location. The initial time required

to freeze these coolant packs can be between 12 and 24 hours depending on the operating

environment.

*For best results, on initial set-up we recommend the RCM is allowed 24 hours to completely

freeze the coolant packs. Following this initial 24 hour “charge” the subsequent “recharge” time

will be much less. By following this extended initial freezing period, you will be ensuring that

consumers are receiving the coldest possible beverage for the best possible extended time

while the RCM is unplugged.

RECHARGEABLE BATTERY INSTRUCTIONS

The RCM features a rechargeable battery that powers the inner fan.

1. Upon rst using the cooler, or when the cooler has not been operated for a long period of time, it

will take 12-18 hours for the battery to charge.

2. The RCM battery is a size N.

3. If the RCM is left plugged in for longer than 48 hours, it will reduce the lifetime of the

rechargeable battery.

BEVERAGE STORAGE

• Leave adequate space between beverage cans to allow air

circulation

• This cooler is primarily for storing beverage cans and plastic

bottles. Avoid putting glass containers in this cooler.

• All beverage products should be properly sealed to avoid

leaking into the cooler.

Instruction Manual

Innovative DisplayWorks, Inc.

RCM-VisID

10 11

CAUTION FLAMMABLE REFRIGERANT

• DANGER – Risk Of Fire Or Explosion. Flammable Refrigerant Used. To Be Repaired

Only By Trained Service Personnel. Do Not Puncture Refrigerant Tubing.

• CAUTION – Risk Of Fire Or Explosion. Flammable Refrigerant Used. Consult Repair

Manual/Owner’s Guide Before Attempting To Install or Service This Product. All Safety

Precautions Must be Followed.

• CAUTION – Risk Of Fire Or Explosion. Dispose Of Properly In Accordance With

Federal Or Local Regulations. Flammable Refrigerant Used.

• CAUTION – Risk Of Fire Or Explosion Due To Puncture Of Refrigerant Tubing; Follow

Handling Instructions Carefully. Flammable Refrigerant Used.

• CAREFUL - Handling, moving and operating of the refrigerator or freezer to avoid

either damaging the refrigerant tubing, or increasing the risk of a leak.

• CAUTION - Component parts shall be replaced with like components and that

servicing shall be done by factory authorized service personnel, so as to minimize the

risk of possible ignition due to incorrect parts or improper service.

DANGER – Risk Of Fire Or Explosion. Flammable Refrigerant Used. To Be

Repaired By Trained Service Personnel Only. Do Not Puncture Refrigerant Tubing.

CAUTION – Risk Of Fire Or Explosion. Flammable Refrigerant Used. Consult

Repair Manual/Owner’s Guide Before Attempting To Service This Product. All

Safety Precautions Must be Followed.

CAUTION – Risk Of Fire Or Explosion. Dispose Of Property In Accordance With

Federal Or Local Regulations. Flammable Refrigerant Used.

CAUTION – Risk Of Fire Or Explosion Due To Puncture Of Refrigerant Tubing;

Follow Handling Instructions Carefully. Flammable Refrigerant Used.

CAUTION FLAMMABLE - R600a Refrigerant

DANGER - Risque d'incendie ou d'explosion. Réfrigérant inflammable utilisé.

Pour être réparé que par un personnel de maintenance qualifié. Ne pas percer

réfrigérant Tubing.

ATTENTION - Risque d'incendie ou d'explosion. Réfrigérant inflammable utilisé.

Consultez manuel / guide de l 'utilisateur de réparation avant de tenter de

réparer ce produit. Toutes les précautions de sécurité doivent être respectées.

ATTENTION - Risque d'incendie ou d'explosion. Aliéner des biens conformé-

ment à la réglementation fédérales ou locales. Réfrigérant inflammable utilisé.

ATTENTION - Risque d'incendie ou une explosion due à la perforation de

tuyaux de réfrigérant; suivre les instructions de manipulation avec précaution.

Réfrigérant inflammable utilisé.

PRUDENCE INFLAMMABLE - R600a Réfrigérant

MODEL VOLUME(L)

RATED

VOLTAGE

RATED

CURRENT REFRIGERANT

RCM-VisID-N23EB

RCM-VisID-NA34B 2.12ft3110-120V/60Hz 1.3A R600/30g

NSF/ANSI-7: Beverage Cooler A refrigerator intended solely for the storage and/or display of

packaged beverage products that are non-potentially hazardous,

such as soda (pop), beer, and wine.

SPECIFICATIONS

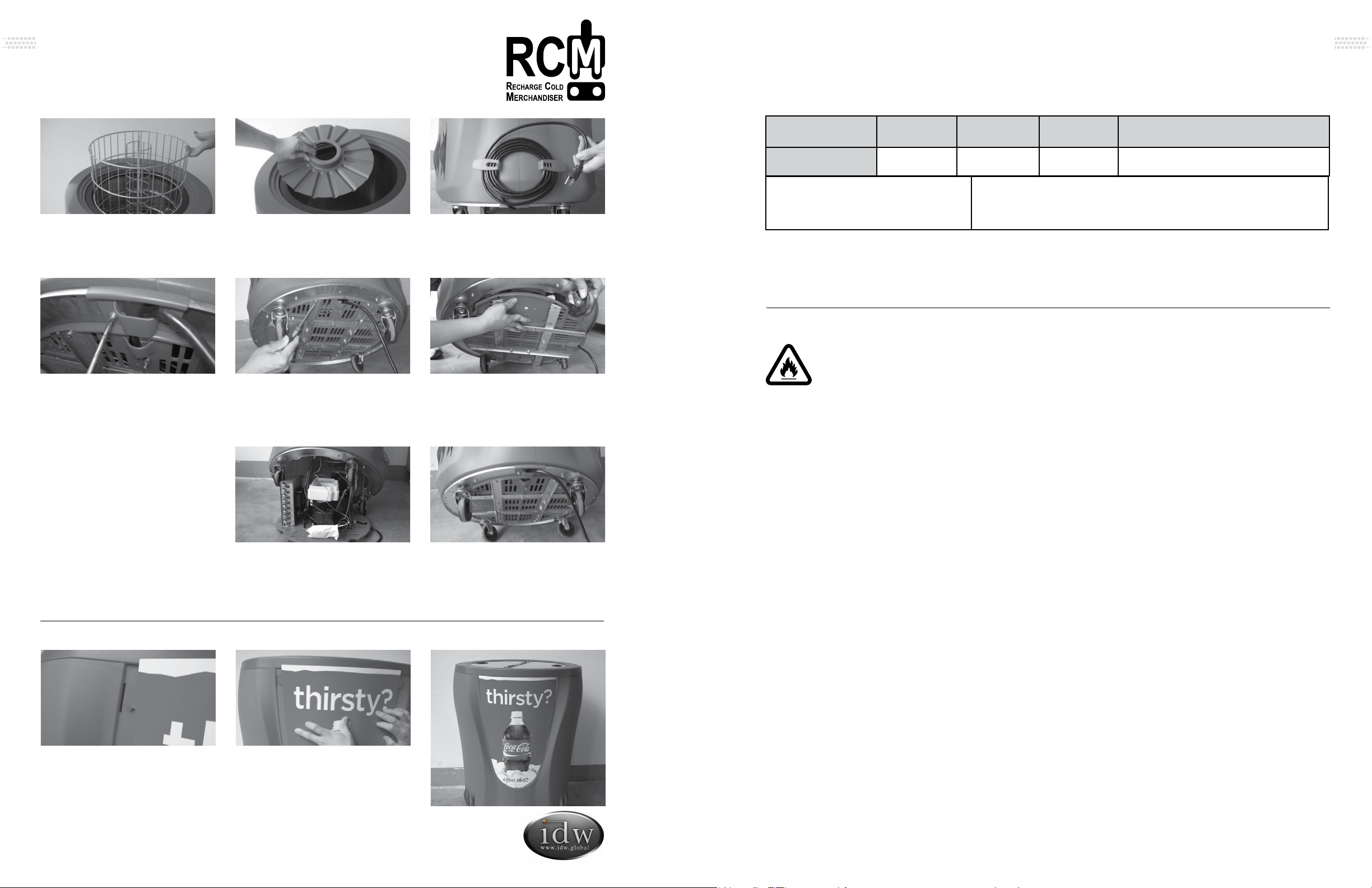

GRAPHIC REPLACEMENT

1. Respectively, insert the (5)

plastic graphic tabs into

the slots of cooler panels.

2. Adjust accordingly.

MAINTENANCE Accessing Cooler Components:

1. Remove the basket from

the inside of the cooler.

2. Remove the baffl er from

the base of cooler.

6. Support the red plastic

base with one hand,

while turning the casters

away to release the base.

8. To re-assemble the

cooler, align the notch

at base with the power

cord. Then reverse steps

1-7.

5. Using a Phillips

screwdriver, unscrew (8)

screws from compressor

metal bracket.

7. Carefully lay plastic base

with compressor on the

fl oor.

4. Lean the body of the

cooler to access the

bottom of cooler. Using

a Philips screwdriver,

remove (2) screws from

the plastic cover of the

power cord.

3. Unwrap the power cord.

Instruction Manual

Innovative DisplayWorks, Inc.

RCM-VisID

12 13

XP - Power Plug

RT - Starting Relay

M2 - Condensing Fan

M - Compressor

SAT - Thermostat

F - Overload Protector

AD - Transformer

MI - Inner Fan

CIRCUIT DIAGRAM

For models: RCM-VisID-N23EB

CIRCUIT DIAGRAM

For models: RCM-VisID-NA34B

• Serial number from the interior wall of the

cooler

• Coolers’ installation address and contact

information

• Installation location hours and operation

• Nature of problem

• Any reports of power interruptions

• Recent service or maintenance completed

on the cooler

• Has the cooler been relocated from original

installation location

• Clear access to the cooler

• Coolers’ instruction manual

Information to provide to your qualifi ed service professional:

Situation Causes

Liquid fl owing noise within cooler • This is the sound of the cooling agent fl owing through the pipes.

Refrigeration system is shutdown for longer periods

of time while temperature inside is still very low

• This refrigerator is well insulated and can maintain a relatively

ambient temperature.

Condensation on door/lid • This may be due to a high indoor humidity or the cooler’s

temperature is set too low. Wipe the door dry with a towel.

Issues Solutions

Cooler is not working properly Please check power supply:

• Check the electrical outlet for power, and that the plug is properly inserted.

• Check to see if the circuit breaker is tripped or the fuse is blown.

• Check if the condenser is free of dirt and debris.

• Check for low voltage

Cooler is not keeping product cool • Provide ample space between all products to ensure proper circulation of air.

• Keep unit away from direct sunlight or other heating source.

• Keep the door closed as often as possible.

• Be certain the cooler is not touching external objects or walls.

Excessive noise • Be certain the cooler is placed on a level surface.

• Be certain the cooler is not touching external objects or walls.

Compressor turns on and off frequently • The room temperature is higher than normal.

• The door is not closed completely.

• The door gasket is not sealed properly.

• There is insuf cient clearance around the cooler.

• The thermostat is not set properly.

• The frequency of cycling will be reduced when all of the product reaches the

set temperature.

TROUBLESHOOTING

The following are NOT malfunctions:

1This refrigerator has been designed and manufactured according to National standards. If there

are any questions during use, refer to this operation manual to help troubleshoot problems.

2 When disposing of the cooler, please remove the door/lid and lock assembly to avoid children

accidentally becoming trapped inside the cooler.

Prior to calling service, check the following:

AFTER SALES SERVICE

Any product has the possibility of malfunction. Please observe the cooler’s operation and any

changes to product being stored. If there are any abnormal cases, refer to the table below. If there

is still no change after following the below instructions, please inform our service center in a timely

manner to avoid a further loss of the unit.

Innovative DisplayWorks, Inc.

8825 Boston Place, Rancho Cucamonga CA 91730

To locate the distributor in your area go to: http://www.idw.global/contact/#distributors

Other manuals for G-Series

12

This manual suits for next models

4

Table of contents

Other IDW Accessories manuals