2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������3

1�1 Symbols used ������������������������������������������������������������������������������������������������3

2 Safety instructions �����������������������������������������������������������������������������������������������4

3 Items supplied������������������������������������������������������������������������������������������������������5

4 Functions and features ����������������������������������������������������������������������������������������5

4�1 Application area ���������������������������������������������������������������������������������������������5

4�2 Restriction of the application area �����������������������������������������������������������������5

5 Function���������������������������������������������������������������������������������������������������������������6

5�1 Measuring principle level �������������������������������������������������������������������������������6

5�2 Measuring principle temperature �������������������������������������������������������������������6

5�3 Features of the unit����������������������������������������������������������������������������������������7

5�3�1 IO-Link ��������������������������������������������������������������������������������������������������7

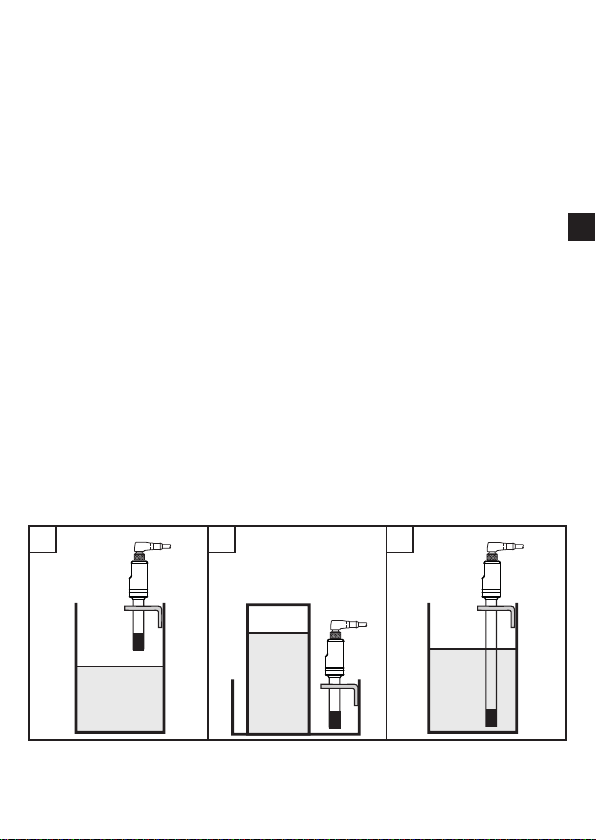

5�4 Application examples�������������������������������������������������������������������������������������7

6 Installation������������������������������������������������������������������������������������������������������������8

6�1 Installation location / environment �����������������������������������������������������������������8

6�2 Installation procedure �����������������������������������������������������������������������������������8

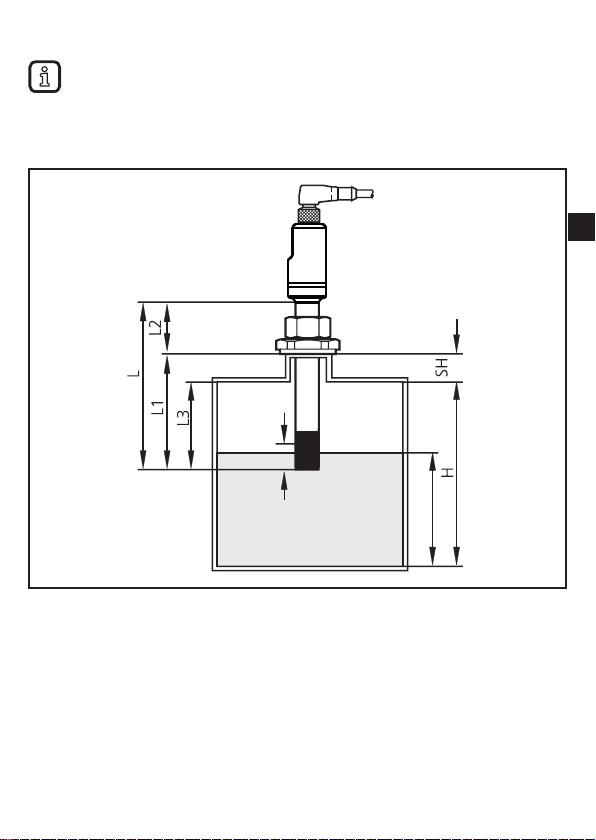

6�3 Set the installation depth �������������������������������������������������������������������������������9

7 Electrical connection������������������������������������������������������������������������������������������10

8 Operating and display elements ������������������������������������������������������������������������ 11

9 Parameter setting ���������������������������������������������������������������������������������������������� 11

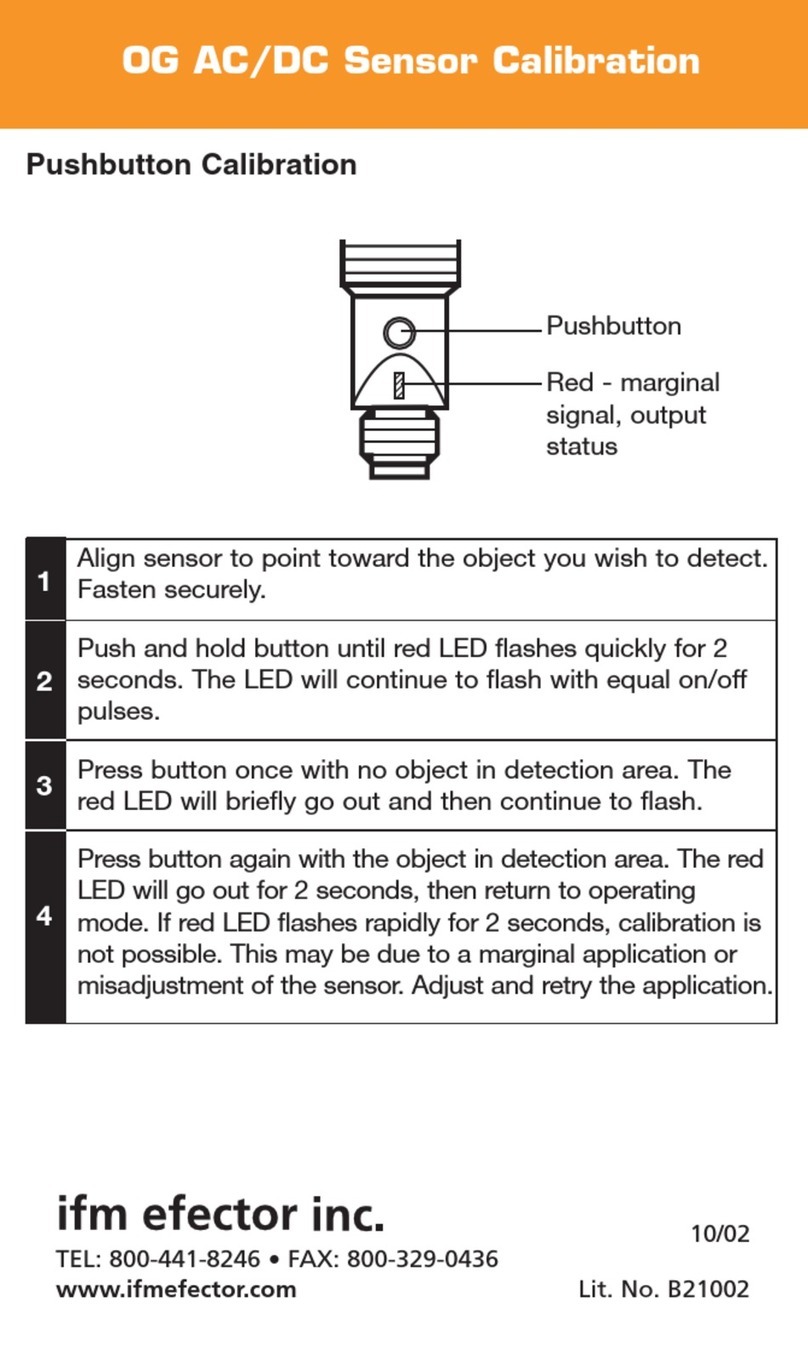

9�1 Parameter setting via the teach button��������������������������������������������������������12

9�1�1 Unlock unit������������������������������������������������������������������������������������������12

9�1�2 Set for empty tank condition ���������������������������������������������������������������13

9�1�3 Set for full tank condition ��������������������������������������������������������������������14

9�2 Parameter setting via IO-Link ����������������������������������������������������������������������15

9�2�1 Parameter setting via PC and IO-Link master ������������������������������������15

9�2�2 Parameter setting via memory plug����������������������������������������������������15

9�2�3 Parameter setting during operation ����������������������������������������������������15

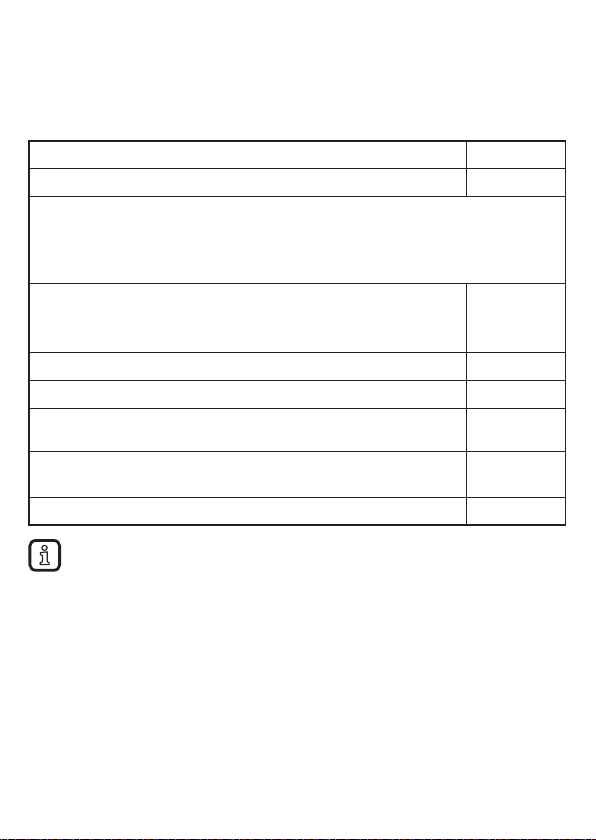

9�2�4 Adjustable parameters and system commands����������������������������������16

9�2�5 Example parameter setting via IO-Link ����������������������������������������������18

10 Operation���������������������������������������������������������������������������������������������������������19

10�1 Function check ������������������������������������������������������������������������������������������19