ISHIDA AC-2000 User manual

Other ISHIDA Scale manuals

ISHIDA

ISHIDA BC-300 User manual

ISHIDA

ISHIDA Uni-3 User manual

ISHIDA

ISHIDA IWX-150/30 User manual

ISHIDA

ISHIDA UNI-7 User manual

ISHIDA

ISHIDA AC-4000B User manual

ISHIDA

ISHIDA Uni-3 User manual

ISHIDA

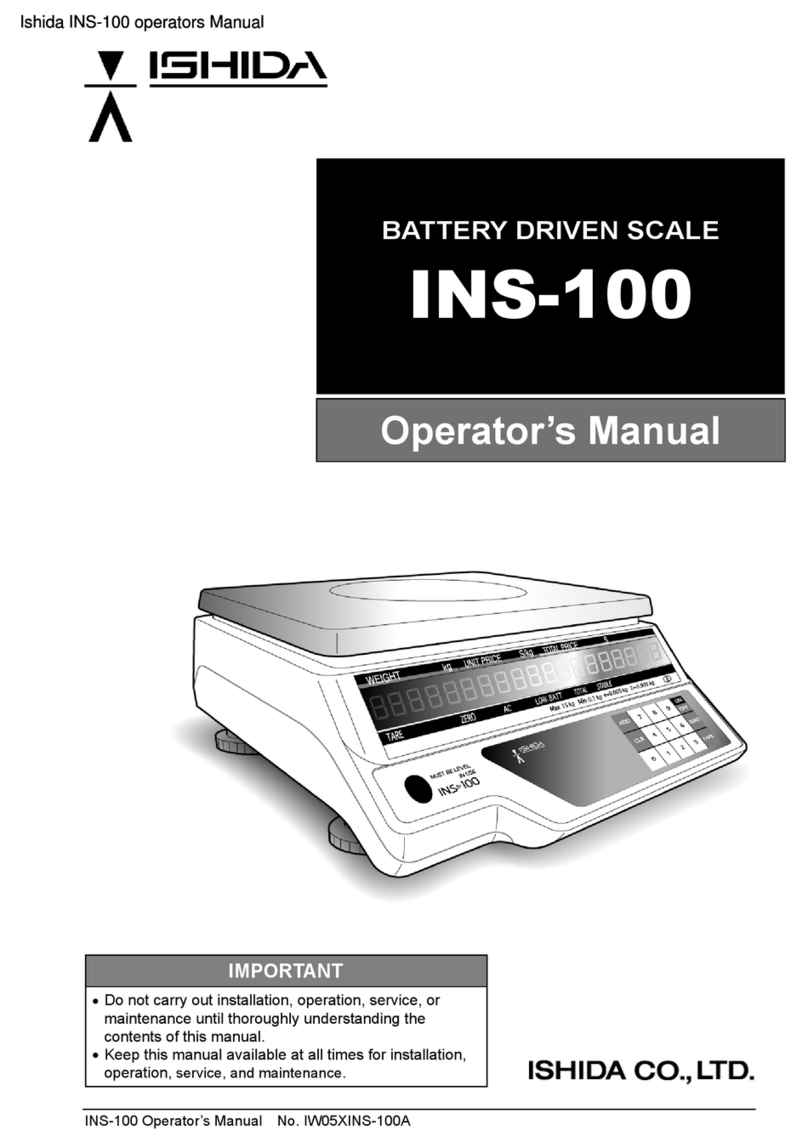

ISHIDA INS-100 User manual

ISHIDA

ISHIDA Astra Instruction Manual

ISHIDA

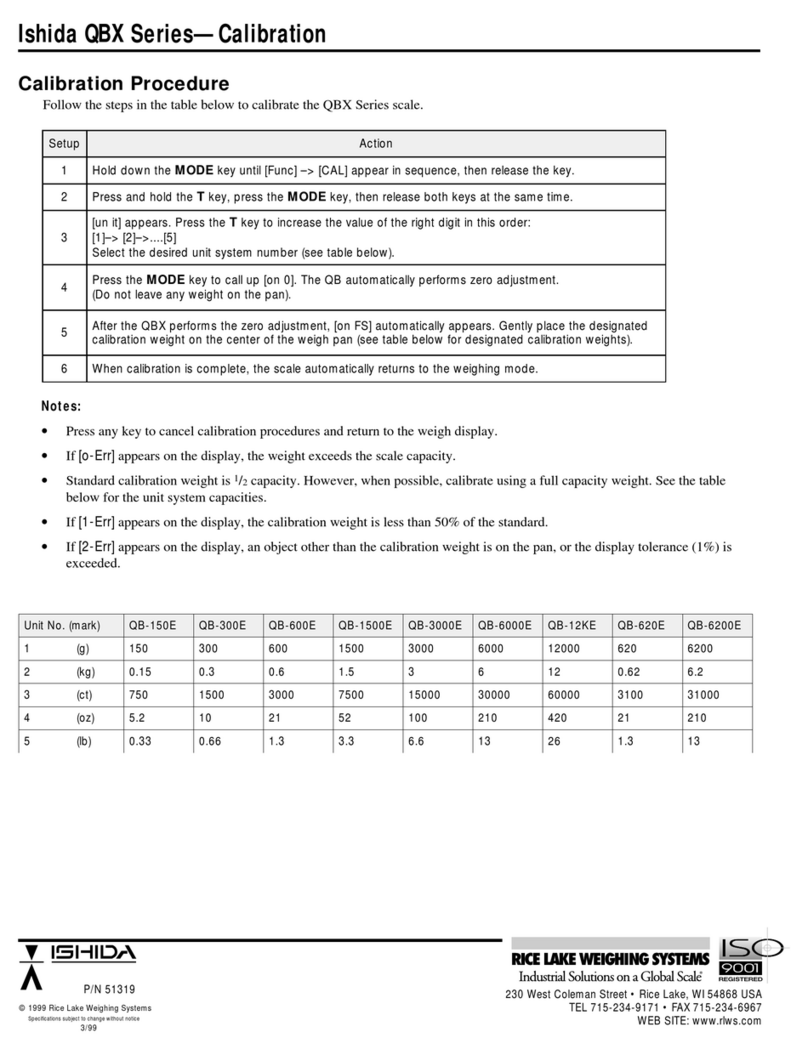

ISHIDA QB-150E Use and care manual

ISHIDA

ISHIDA IGX Series User manual

ISHIDA

ISHIDA SR-2000 alpha User manual

ISHIDA

ISHIDA UNI-7 User manual

ISHIDA

ISHIDA IGB-60 User manual

ISHIDA

ISHIDA IP-AI User manual

ISHIDA

ISHIDA AC-4000 Series User manual

ISHIDA

ISHIDA Astra II Bench Installation manual

ISHIDA

ISHIDA AC-4000 Series User manual

ISHIDA

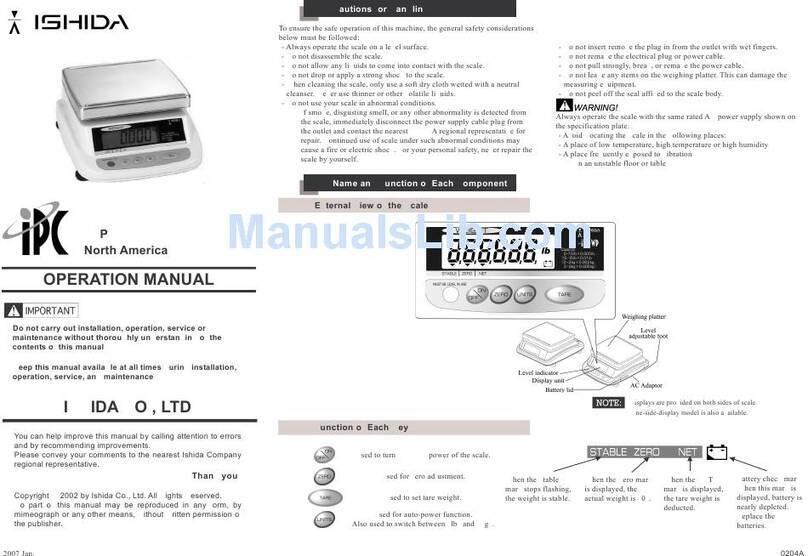

ISHIDA IPC-WP User manual

ISHIDA

ISHIDA Uni-5 User manual

ISHIDA

ISHIDA INS-100 User manual