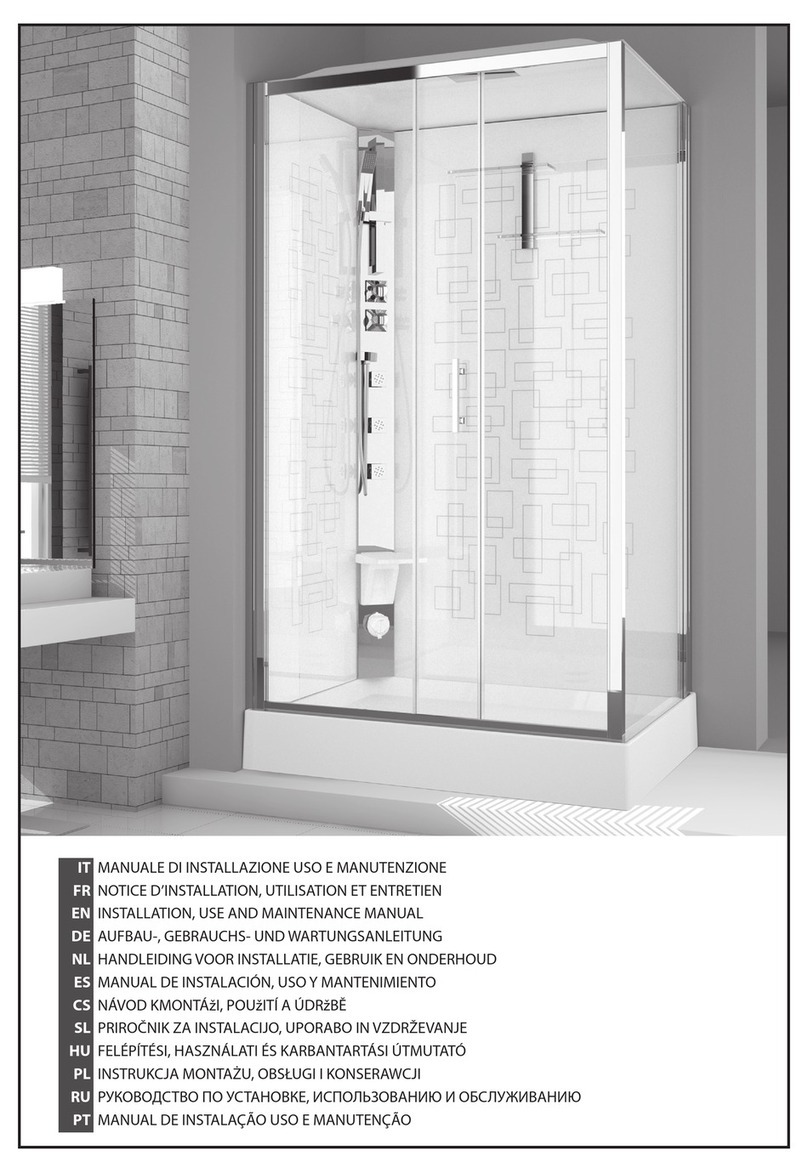

8

Q(10) Assemble the bracket on the frame and, after having

checked the perpendicularity, attach it to the wall.

(detail 1) Given that the perpendicularity of the frame will

be adjusted after assembling the external cornice, we rec-

ommend not fully tightening the screw (V) .

Installing glass panels

Q(11) Place the prole inside the compensator and resting

on the tray; check that the distance with regards the inner tray

rim is equal to the distance between the panel frame prole and

the rim itself.

After having checked the perpendicularity, attach the prole to

the wall.

ATTENTION: when moving glass panels, ONLY use suc-

tion lifters, suited to hold the weight of the glass pan-

els. Also use suitable protective gloves.

Q(12) Insert the glass, as indicated, inside the panel frame;

let it slide across the entire length, to the very edge of the op-

posite prole.

Q(13) Insert the second glass inside the prole, attached to

the tray base and let it slide across the entire length, to the edge,

of the vertical prole.

ATTENTION: check that the glass side displaying the

label faces inwards towards the inside of the shower

enclosure.

Installing the cornice

Q(14) Remove the vertical element which will be positioned

on the wall (drain side) and attach the bracket to the upper part

of this same element (NB: in the instance where you are assem-

bling a cornice to a horizontal surface, the bracket may be attached

at a later stage).

The vertical element does not feature a magnetic prole (M).

Remove the lower element (identiable owing to the two holes

present on the internal part) and thread the short, metal dowel

inside the element itself.

Q(15) Remove the remaining vertical element and the up-

per element. Place silicone, as indicated, on the lower prole and

assemble the elements, checking connections for breakages. At-

tach the elements together.

Q (16) Working from the inside, place a line of silicone on

the lower cornice element; hook up the cornice to the screws

present on the tray.

Q (17) Check the perpendicularity of the panel frame and

permanently x the screws (V).

Insert the cornice to the glass (A) and panel (B), right up to the

edge; attach the cornice bracket to the panel frame bracket.

Installing the roof

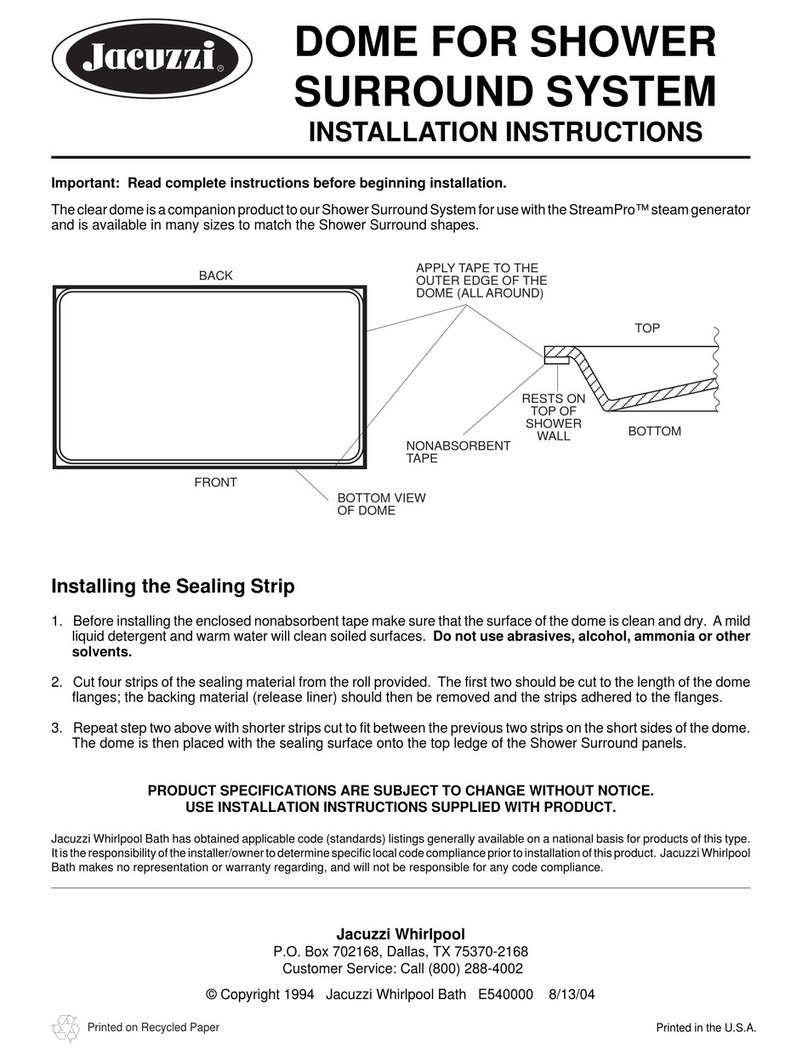

Q(18a-18b-18c) Remove the protective lm and attach the

prole to the roof, checking that it is ush. Apply the gasket.

The hole arrangement varies depending on the installation

corner type.

Q(19) Apply lubricant material (e.g. vaseline) to the panel-

frame joints (to facilitate subsequent panel installation).

Then apply the spacers to the glass proles and assemble

the roof, so that it links up with the glass and the panel-frame.

Ensure you hook the roof in the grooves present on the up-

per cornice element.

Hydraulic and electrical connections

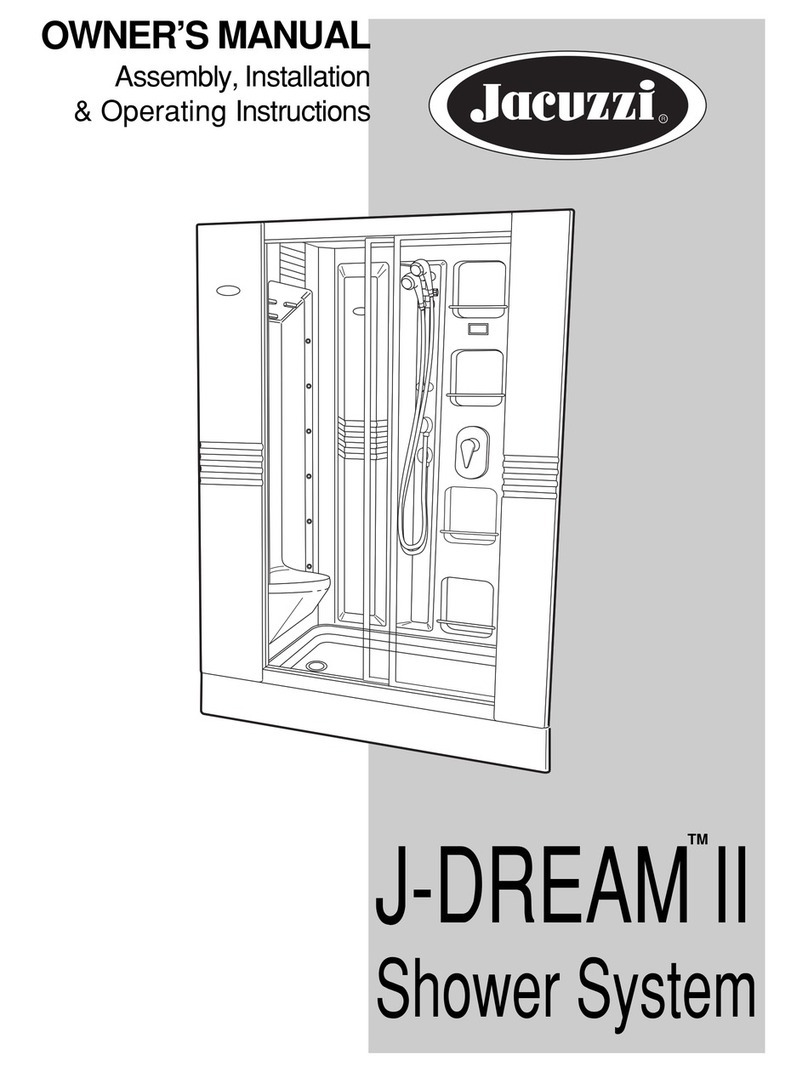

Q (20) Draw the panel to the brassware and connect the

brassware to the wall connections.

Also assemble the shower door shutter.

Carry out the following connections:

- with the shower head (A);

- with the waterfall (B);

- with the spray jets (C).

Q (21, part.1) Connect the light cable coming from its re-

spective box to the box present on the roof.

Carry out the following connections:

- with the equipotential terminal board;

- with the emergency alarm circuit (see also the relative chapter);

- with the building's electrical supply system.

Also refer to the wiring diagram.

IMPORTANT: for Countries where 220-240V voltage is

supplied by a two-phase system (L+L), the connection

has to be made on terminals L and N anyway.

We recommend using clamps to gather tubes and cables (

21) and checking that no obstacles which could hinder as-

sembly and attachment of the panel (see 22) are present.

QConnecting the alarm (where necessary)

There are two terminals inside the electric control box (designated

with “ALL”) to which the alarm circuit should be connected; these

terminals are open contacts powered by a relay.

- When the “alarm”key is pressed, a relay inside the electric con-

trol box activates the emergency call device for approximately

15 seconds. The call warning (alarms, buzzers, lamps, etc.) may

be powered to either 220/240 V or low voltage, however with

maximum power absorption equal to 5 A.

- The alarm circuit connection must incorporate a cable with

characteristics not inferior to H 05 VV-F 2x0,75 mm2. This cable

type must be used in order to ensure that the cable clamp at-

tached to the box provides adequate protection as specied by

legislation.

8