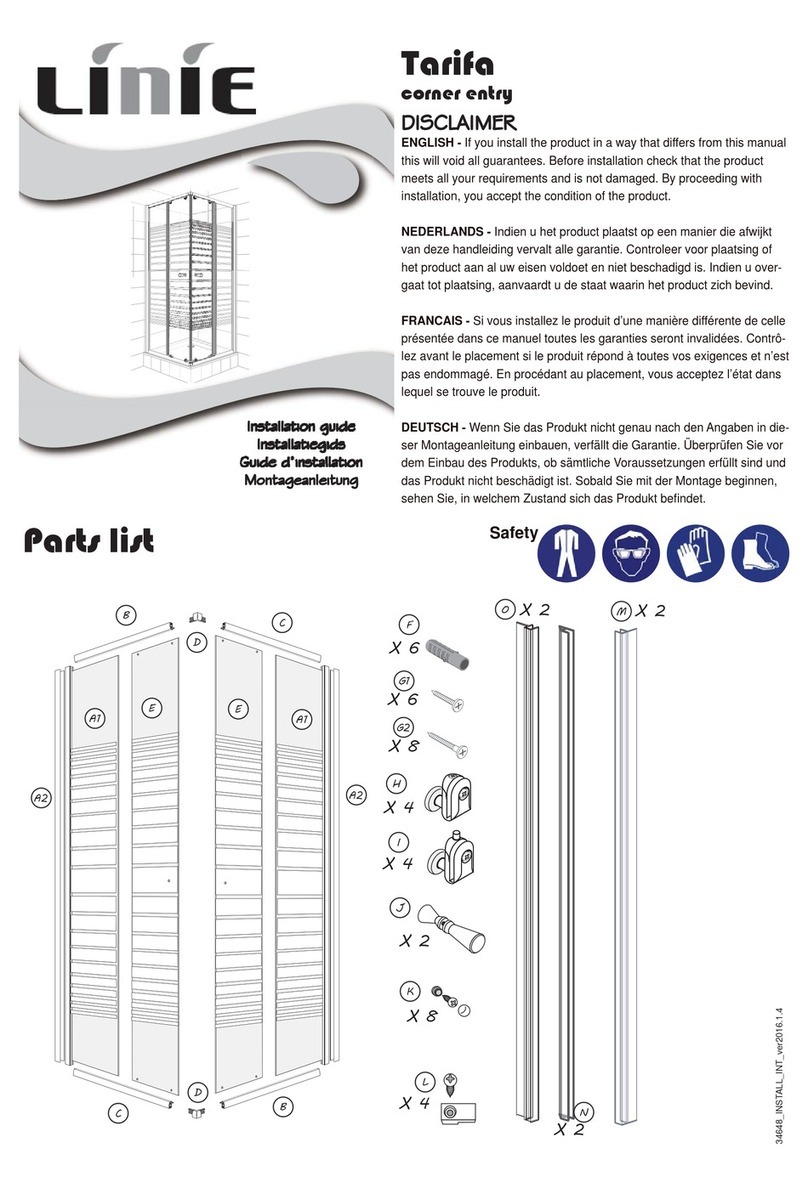

5

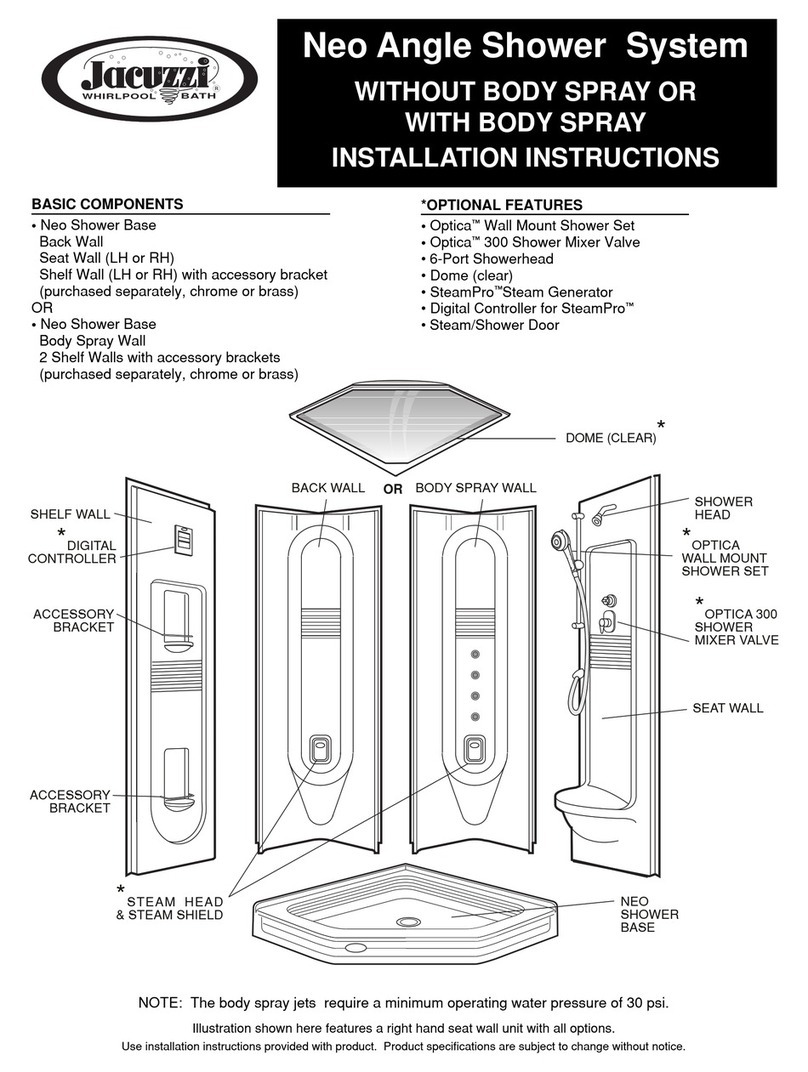

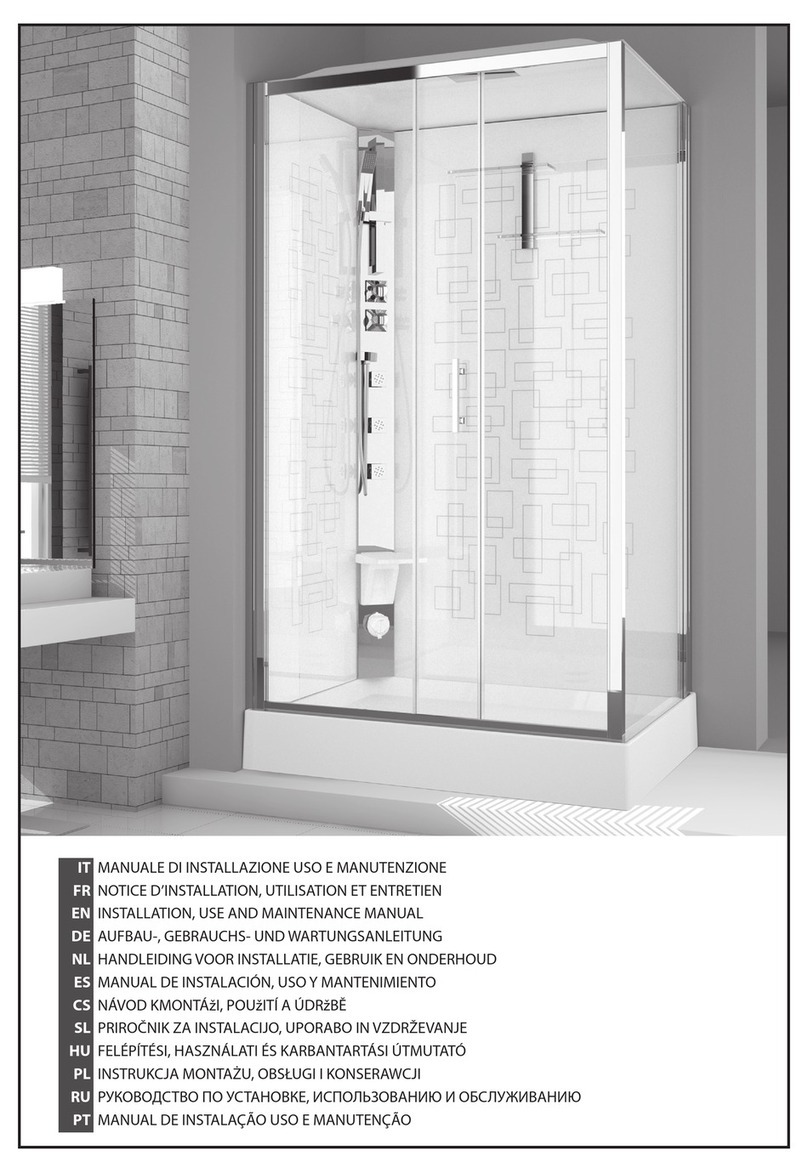

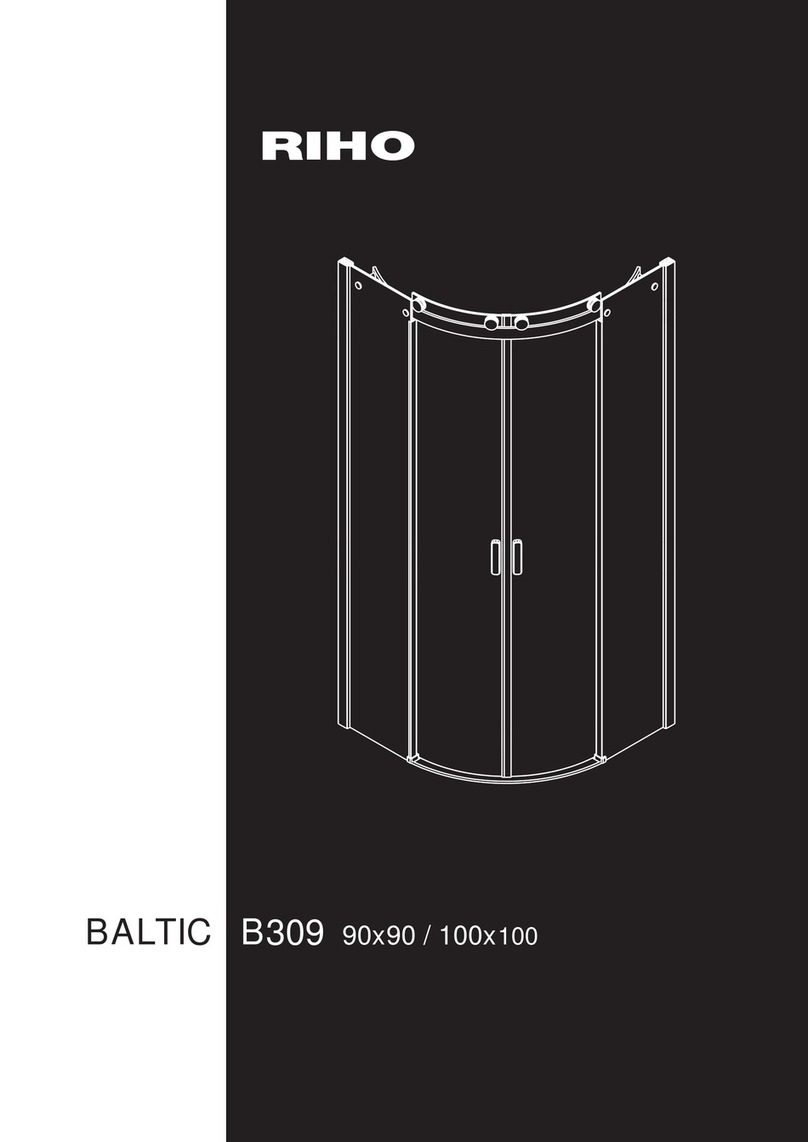

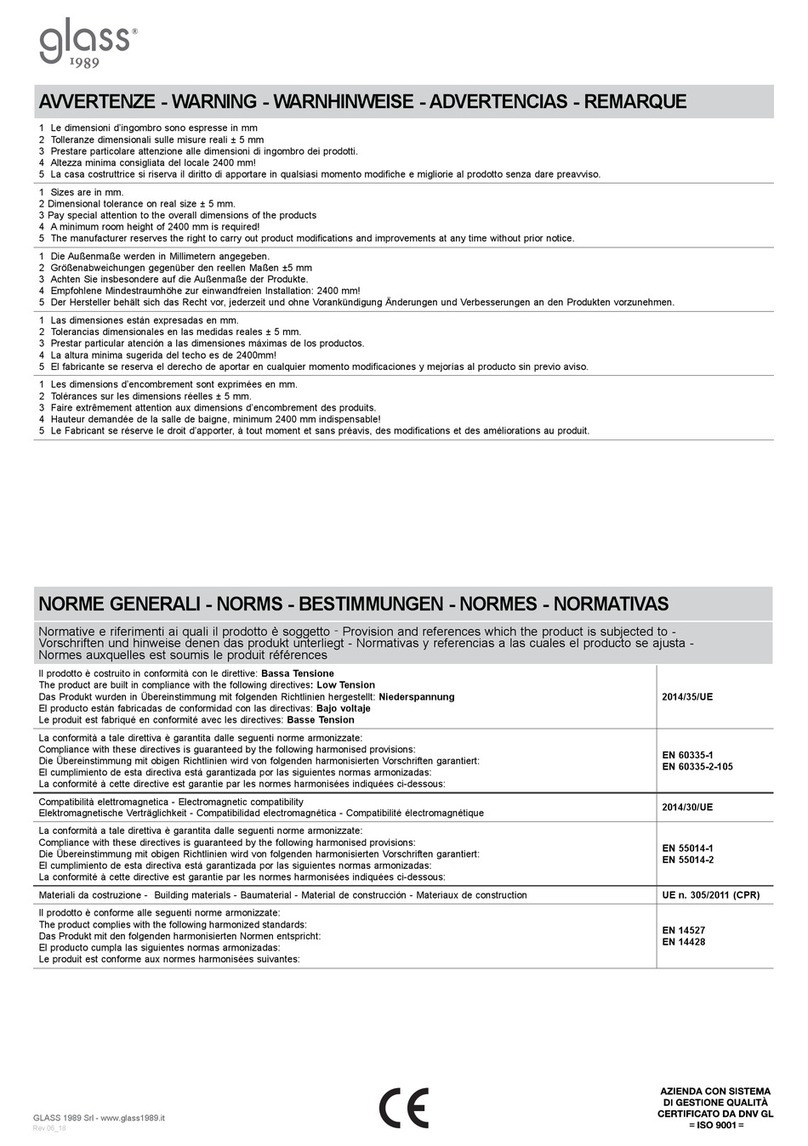

PRELIMINARY ROUGH-IN

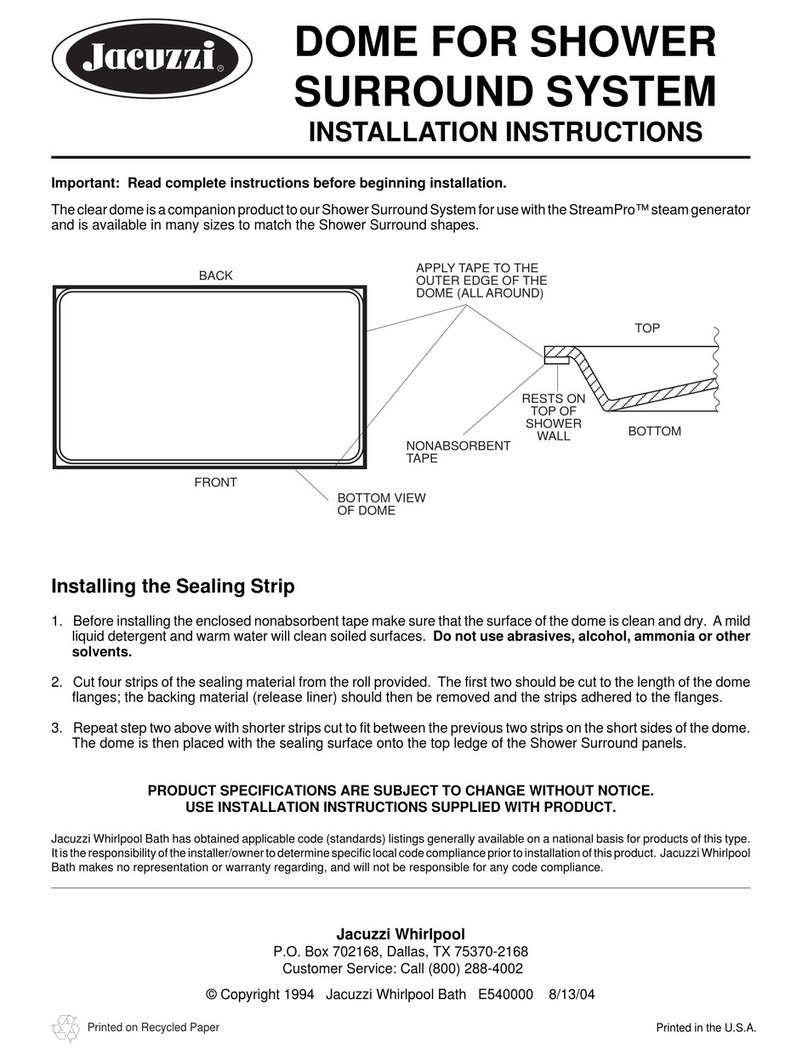

SPREAD MORTAR OR LEVELING COMPOUND ETC.

EVENLY OVER ENTIRE AREA

STRAINER

DRAIN

ASSEMBLY

SILICONE

SEALANT

SHOWER BASE

RUBBER WASHER

FIBER WASHER NUT

APPLY LUBRICANT

Thefloorstructurebeneaththeunitmustbeableto

support a total weight of the unit and bather. Refer

to the table under total weight.

STEP 1

Provide an opening in the subfloor no less than 5" x 5"

square. This opening should be located on the center

linesoftheshowerbasedrainhole(SeeProductChart).

The opening is to accommodate a 2" waste pipe. The

waste pipe should be 1/4" to 1/2" above the surface of

the subfloor.

2 WALL BASE INSTALLATION

STEP 3

If the subfloor is level, no other preparation is neces-

sary. Youcanproceedtoinstallthe showerbase. Ifthe

subfloor is not level, level shower base by spreading

floor leveling compound, mortar, plaster or minimal

expansion structural foam with a minimum density of 5

lbs./cubic feet EVENLY over ENTIRE area where base

will be installed. The compound used MUST make

contactwiththeentirebottomsurfaceofthebase. Both

sides of a joint or splice of subfloor should be level to

each other. Level and support waste pipe cutout area

greater than 5" x 5". The base is NOT to be supported

by the tile flange.

INSTALLATION INSTRUCTIONS

STEP 2

Remove the stainless steel strainer from the drain

assembly. Disassemble the locknut and two gaskets

from the back of the drain assembly. Apply a 1/4" bead

ofcaulking(silicone)tothedrainholeandinsertthedrain

assembly. Replace the rubber washer, fiber washer,

and lock nut in that order. Hand tighten the locknut.

Remove excess sealant from finished side.

Apply a lubricant (common household liquid soap

works well) to the inside of the rubber seal of the drain

assembly.

90°

5"x5" OPENING

(MIN. AS POSSIBLE)

2" WASTE PIPE

90°

90°

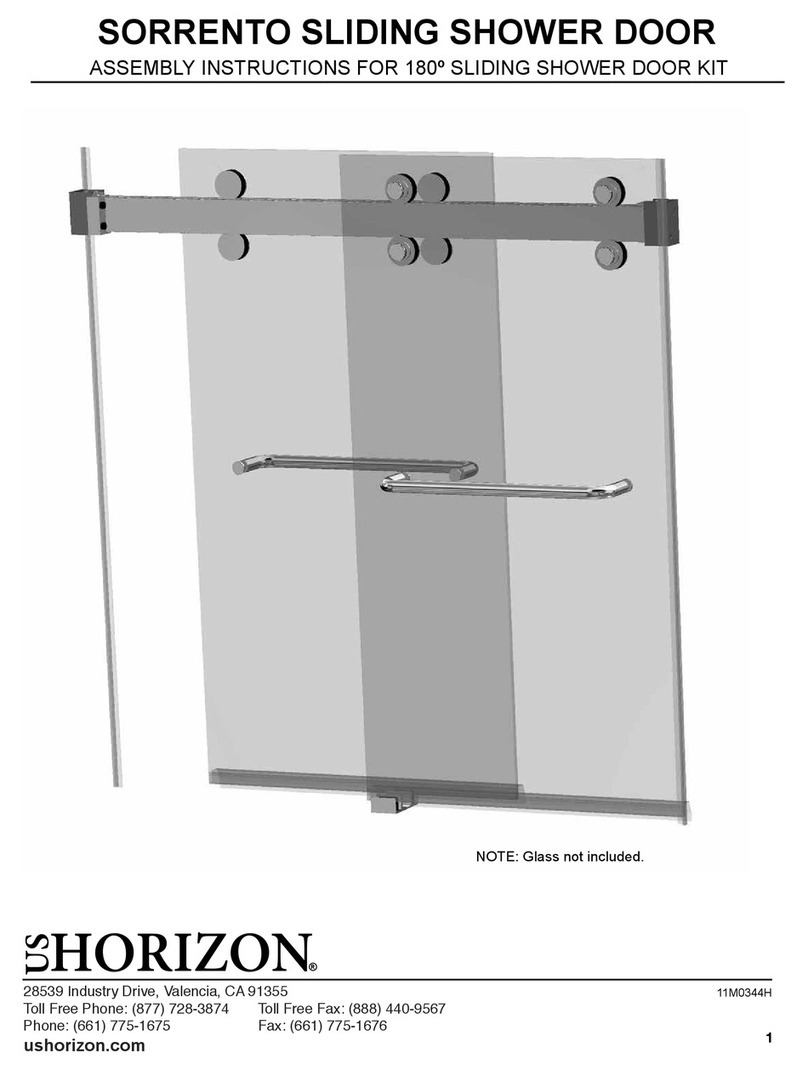

As shown in top view, 1/2" copper pipes are provided

toconnecttothewatersupply. Alsoprovidedare2loose

45°elbows as shown for installation in Detail 1.

CAUTION: A nonflammable protective barrier must

be placed between soldering work and base unit to

prevent damage to the base.

Whenconnectingthesupplylines,thetoeplatecanbe

notched to accommodate the pipes.

Thepipeunderthebasecanbecuttolength. Todoso,

removethepipeclampsunderthebase,cutthepipeand

reinstall pipes.

45°ELBOW

PROVIDED (2)

NOT PROVIDED

STUD

WALL

DEATAIL 1