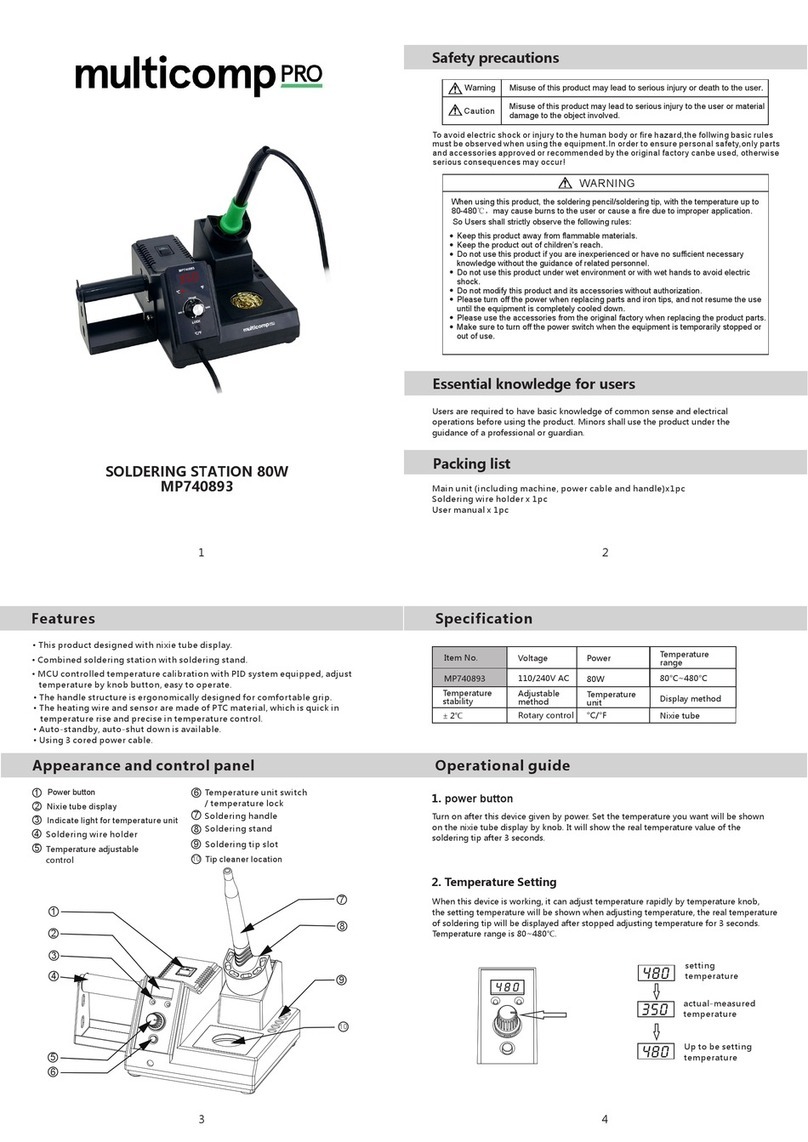

9

Changing Tips

This operation should be

done while the tip is hot, at

a minimum temperature of

250°C, so that any tin left

inside is in molten state.

- Unscrew the tip to be

replaced, with the aid of the

spanner supplied.

- Fit the new tip, and tighten

up with the spanner to

achieve a good air tightness.

250ºC min.

Desoldering process

Use the tip model with a larger diameter than the pad to be desoldered, so as to achieve maximum

aspiration and thermal efficiency.

1. Apply the desoldering iron

tip so that the component

terminal penetrates within its

orifice.

After pressing the desoldering key there is a slight delay until the self-contained vacuum pump

stops, this is to make sure that the vacuum circuit is completely empty.

If any solder remains are left on any terminal after attempting to desolder it, resolder it with fresh

solder and repeat the desoldering operation.

2. When the solder liquefies,

start gently to rotate the

desoldering tip so that the

compo nent’s terminal can be

eased away from the sides.

3. Press then, not before, the

vacuum pump push-button

just long enough to aspirate

the solder.

www.jbctools.com

123