10

1236 Lathe

5.5 STANDARD ACCESSORIES

• Electrical equipment & Motor 2 HP

• Set of change gears - 1 set

• Center sleeve M.T. No. 5x3 - 1 pc.

• Two centers M.T. No.3 - 1 set

• Threading dial indicator - 1 set

• Toolbox; set of spanners & Keys - 1 set

• 4-ways turret toolpost - 1 pc.

• Toolpost wrench - 1 set

• 6 inch (150mm) dia. backplates - 1 pc.

• 3 - jaw scroll chuck 6 inch (150mm)

• Face plate 10 inch (250mm)

• Steady rest

• Follow rest

• Coolant pump equipment

• Splash guard

5.6 OPTIONAL ACCESSORIES

• 4 - jaw independent chuck 8 inch (200mm)

• Taper turning attachment

• Quick change toolpost

• Micro carriage stop

6.0 INSTALLATION

1. Finish removing all crate material from around lathe.

2. Unbolt lathe from shipping pallet.

3. Choose a location for the lathe that is dry and has

sufficient illumination (consult osha or ansi standards

for recommended lighting levels in workshop

environments).

4. Allow enough room to service the lathe on all four

sides, and to load and off-load work pieces. In addition,

if bar work is to be performed, allow enough space

for stock to extend out the headstock end. If used in

production operations, leave enough space for stacking

unfinished and finished parts.

5. The foundation must be solid to support the weight of

the machine and prevent vibration, preferably a solid

concrete floor.

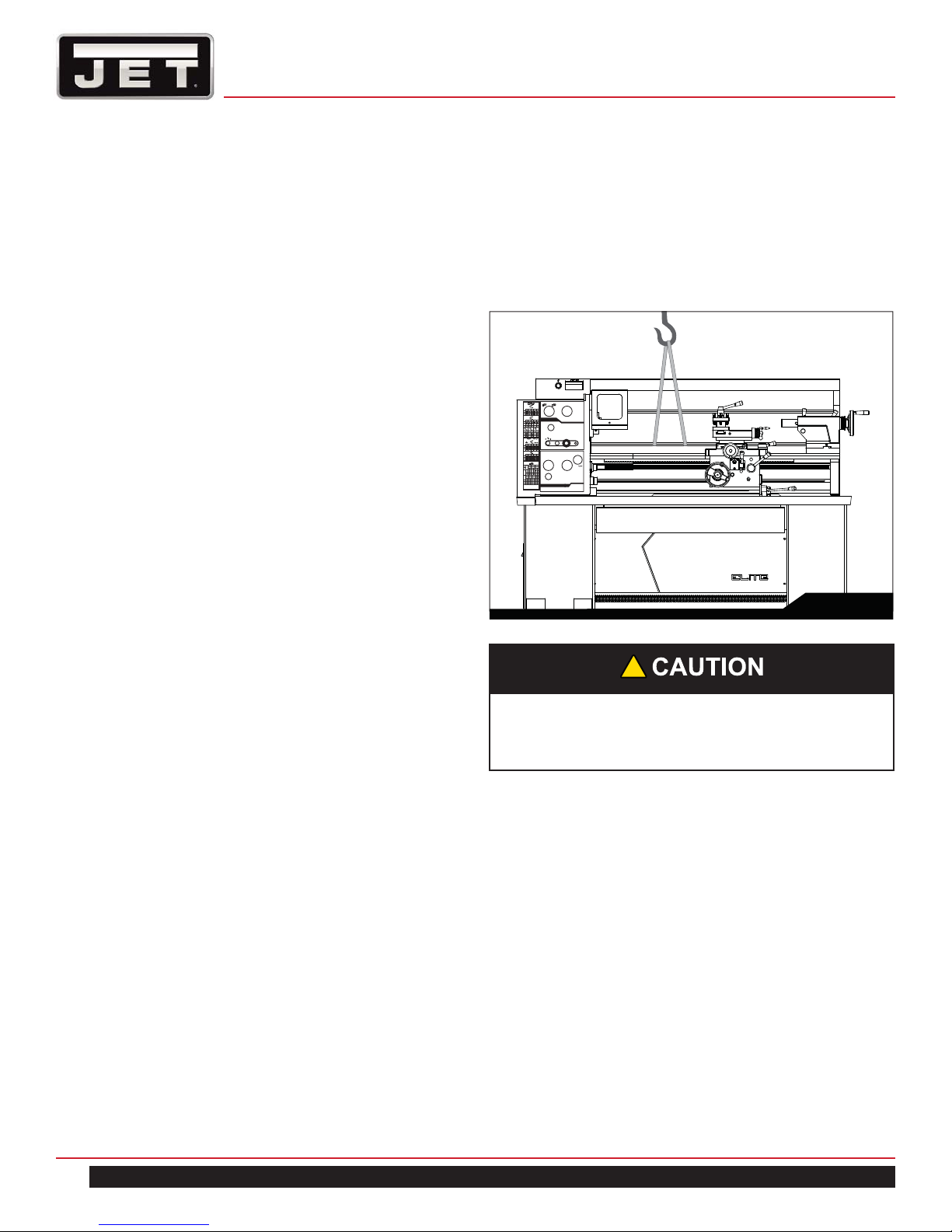

6. The lathe’s center of weight is near the headstock.

Before lifting, move the tailstock and the carriage

(release carriage lock, see section 11.0) To the right

end of the bed and lock them.

7. With properly rated lifting equipment, slowly raise lathe

off shipping pallet. (See Figure 4). Do not lift lathe by

the spindle.

HL

RPM

TOOGLE

STOPLATHE TO

CHANGESPEED

32 36 40 48 56

28

20 24

10 12 14

18

9

16

8

0.00280.0025 0.0023 0.0019 0.0016

0.00570.0051 0.0046 0.0038 0.0032

0.01150.0102 0.0092 0.0076 0.0065

0.01150.0102 0.0092 0.0076 0.0065

0.02300.0204 0.0184 0.0153 0.0131

0.04600.0409 0.0368 0.0307 0.0263

8

22

11

5.5

23

11.5

5.75

3 3 3

910 12 14

75 6

2.5 3 3.5

4.5

2.25

4

2

T.P.I

127

26

52

127

52

26

127

40

44

127

40

46

127

40

52

26

13

6.5

127

26

52

inch

127

52

26

mm

120

127 26

52 35

40 30

50

PC

MM

0.5 0.6 0.8

0.8 0.90.9

1.81.61.751.51.21.0

2.0 2.4 3.0 3.5 3.2 3.6

0.75 0.875

30

6050605030 30304040

1.8751.125 1.25

3.752.25

1.0

2.0

4.0 4.5 5.0 7.5 8.0

4.0

2.0 2.4 2.5 3.0

4.8 5.0 6.0

9.6 10 12

2.5

Leadscrew8 TPI

B

2

3

AC

1

45

Fig. 4

!

Confirm that all suspension equipment is properly

rated and in good condition for lifting lathe. Do not

allow anyone beneath or near load while lifting.

8. The lathe can be placed upon the cast iron leveling

pads under each foot hole, and adjusted using the

adjusting bolts with hex nuts. Or, it may be secured

to the floor using bolts placed head-down in the

concrete, and using shims where needed to level

the machine. Refer to Figure 1 for mounting hole

dimensions.

6.1 LEVELING THE LATHE

It is imperative that the lathe be on a level plane; that is,

where headstock and tailstock center points remain aligned

throughout the tailstock travel, with the bed ways absent of

twist and thus parallel to the operational center line.

A lathe which is not properly leveled will be inaccurate,

producing tapered cuts. Also, the center point of the

tailstock will vary as it is positioned along the bed, thus

requiring constant readjustment of the set of the tailstock.