Johnson Controls F62AA User manual

Other Johnson Controls Security Sensor manuals

Johnson Controls

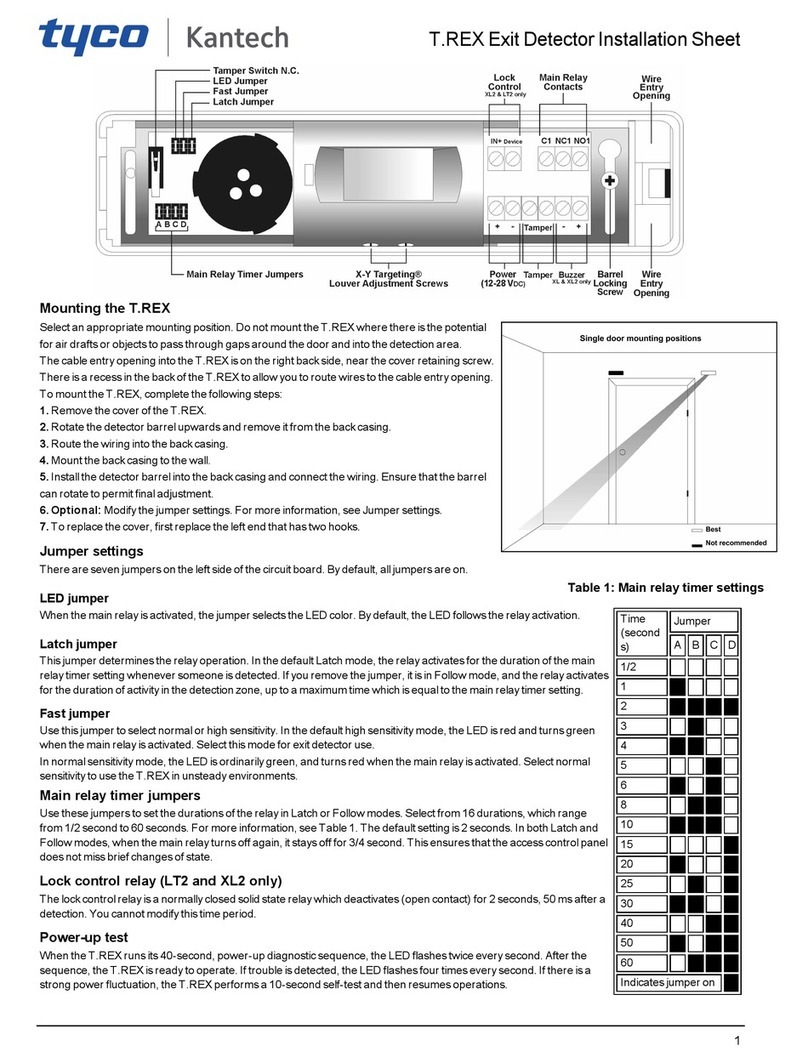

Johnson Controls Tyco Kantech T.REX Assembly instructions

Johnson Controls

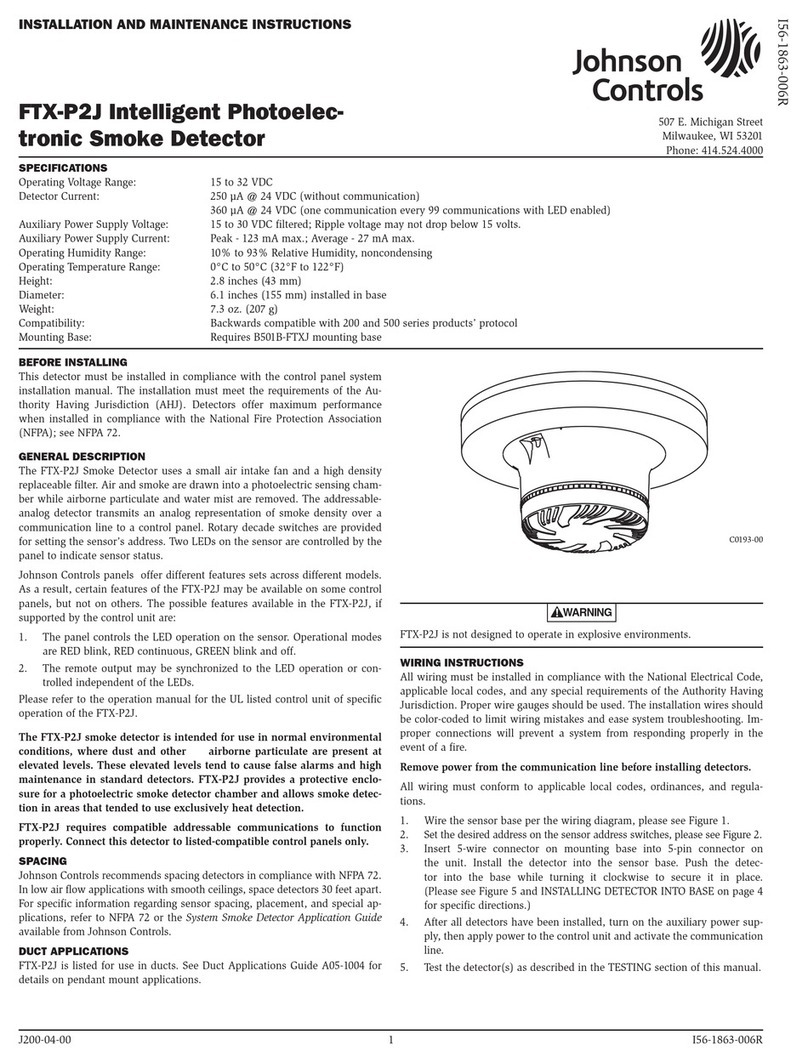

Johnson Controls FTX-P2J User manual

Johnson Controls

Johnson Controls DSDN User manual

Johnson Controls

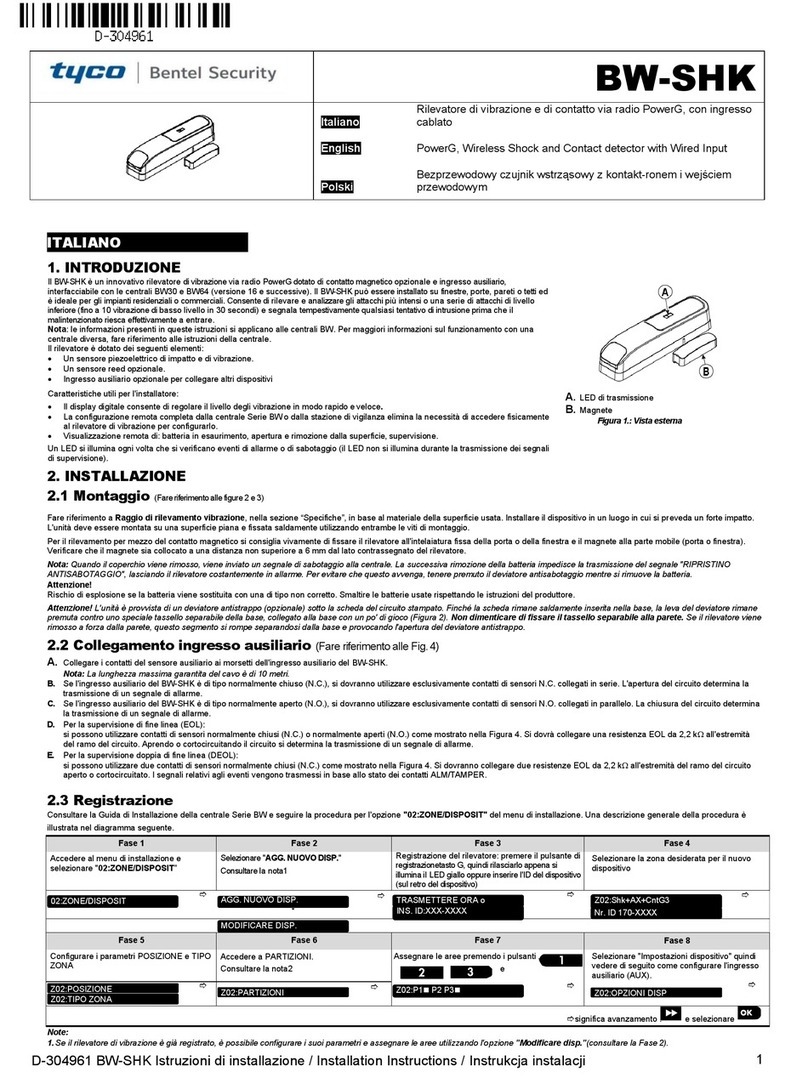

Johnson Controls tyco Bentel Security BW-SHK User manual

Johnson Controls

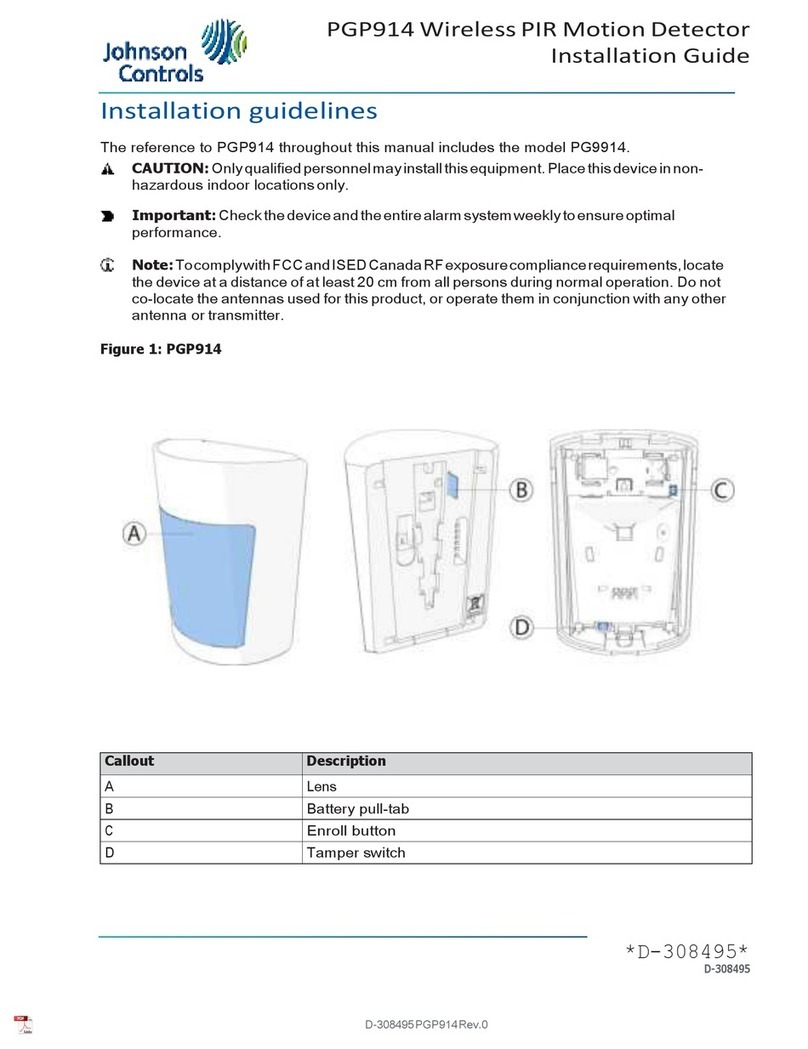

Johnson Controls PGP914 User manual

Johnson Controls

Johnson Controls PG9200AX User manual

Johnson Controls

Johnson Controls tyco Bentel Security BW-DTM User manual

Johnson Controls

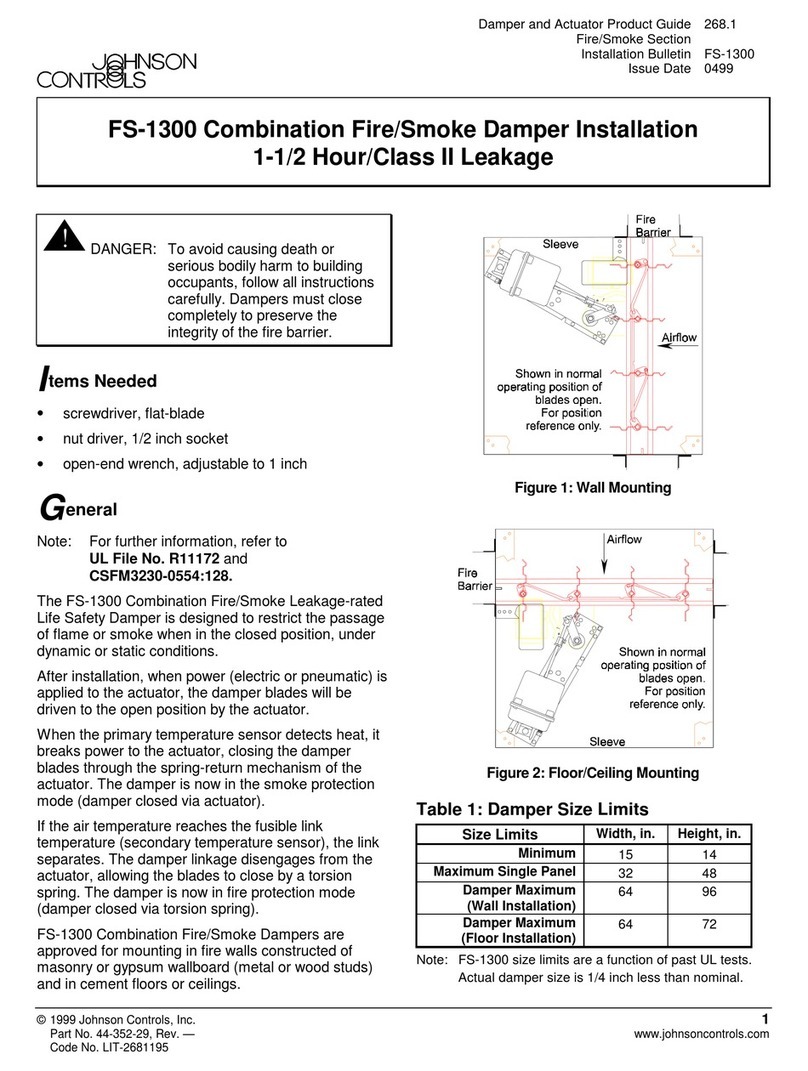

Johnson Controls FS-1300 User manual

Johnson Controls

Johnson Controls PG8932 User manual

Johnson Controls

Johnson Controls HTD-432 PG2 User manual

Johnson Controls

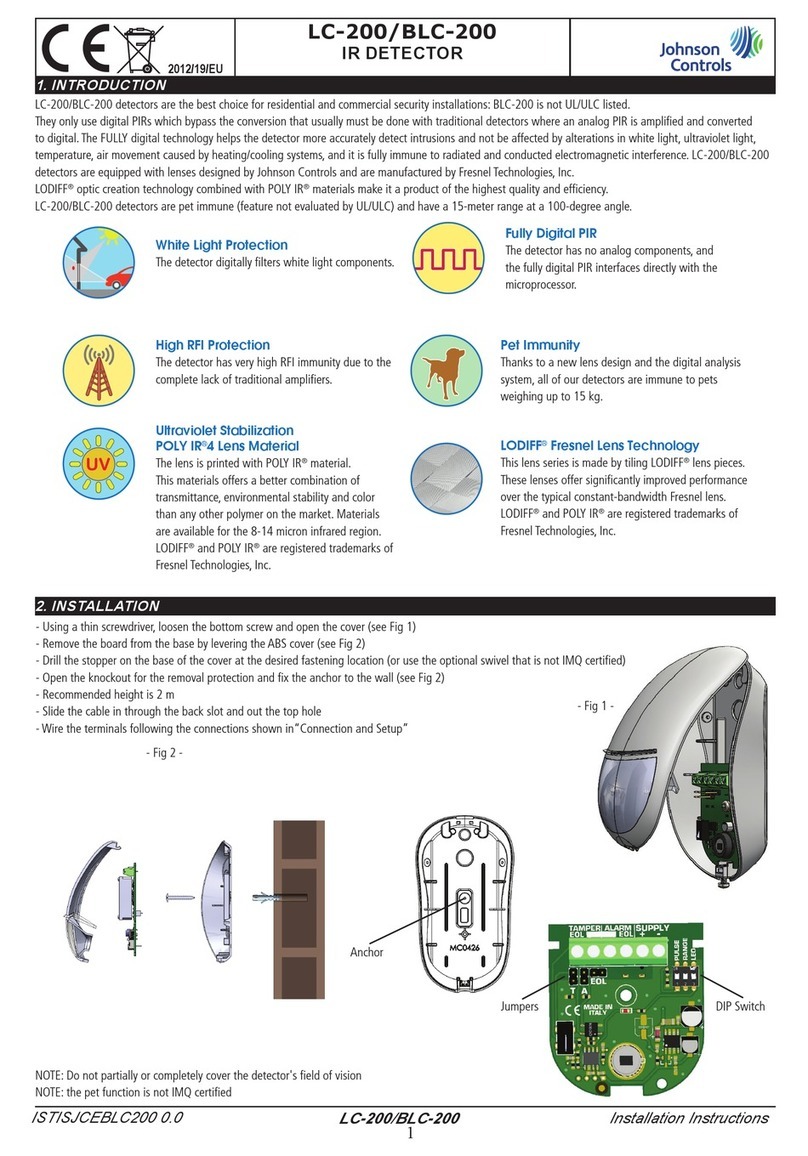

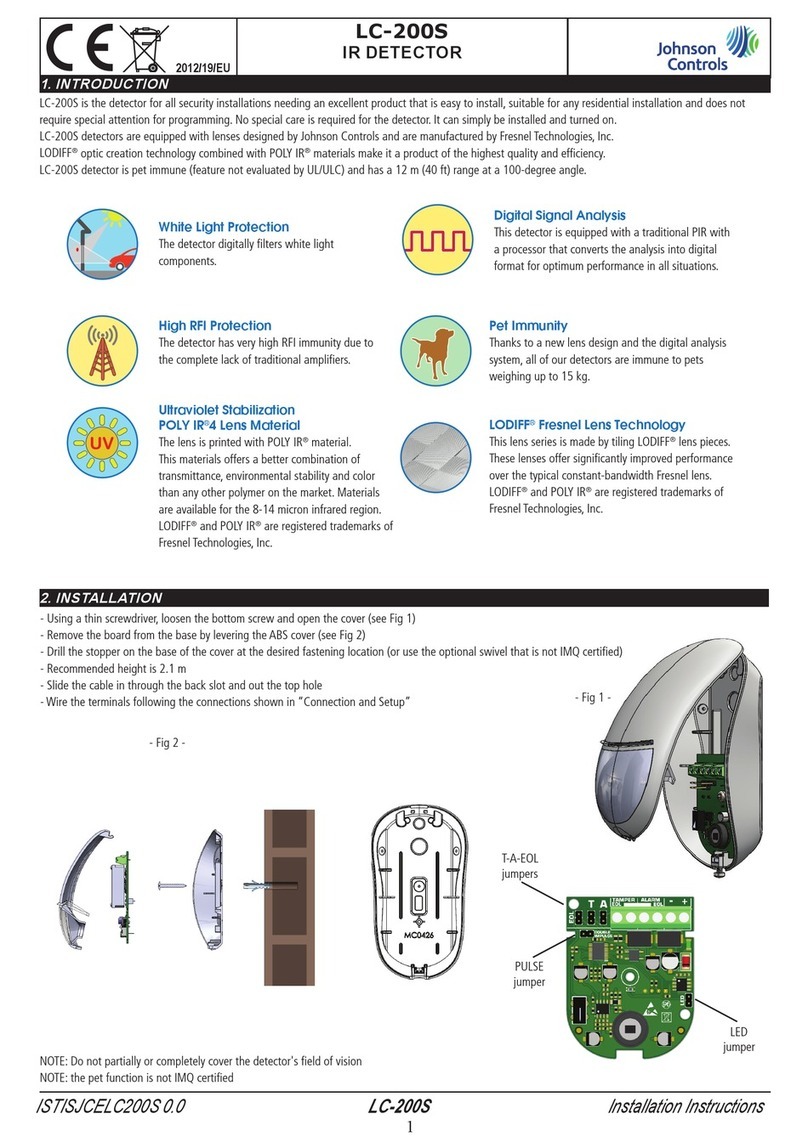

Johnson Controls LC-200S User manual

Johnson Controls

Johnson Controls RLD-H10G User manual

Johnson Controls

Johnson Controls tyco Bentel Security BW-IRC User manual

Johnson Controls

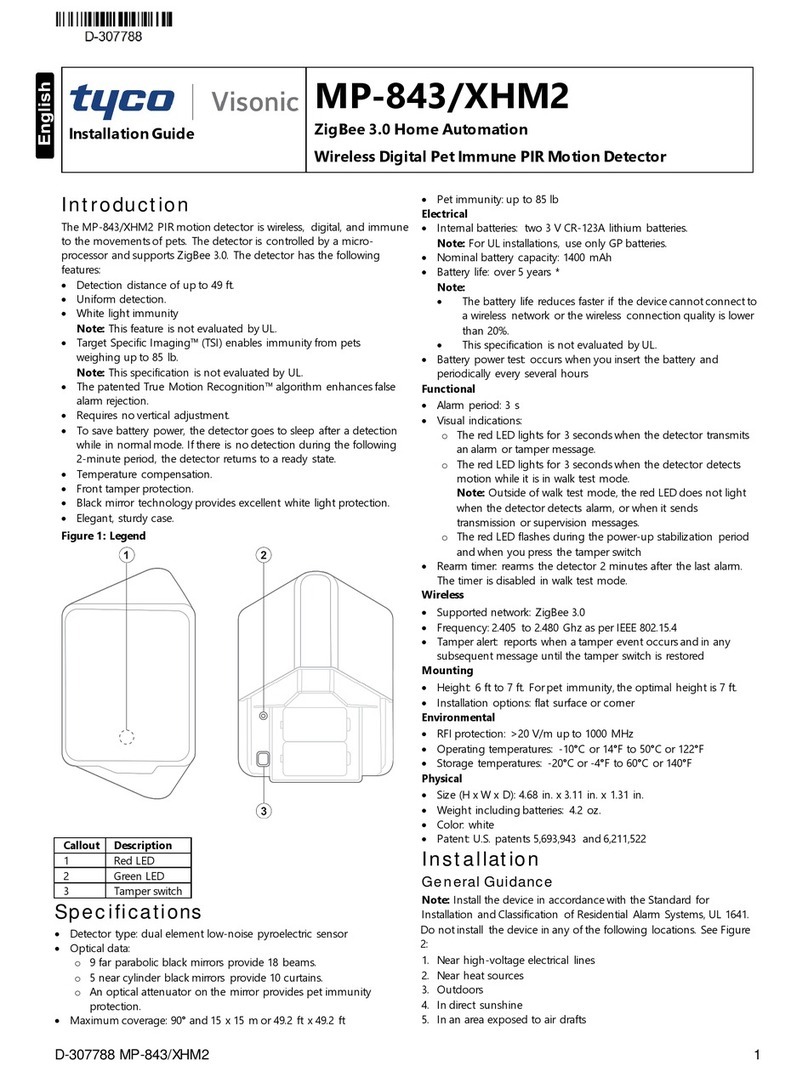

Johnson Controls Tyco Visionic MP-843/XHM2 User manual

Johnson Controls

Johnson Controls PG9350SL User manual

Johnson Controls

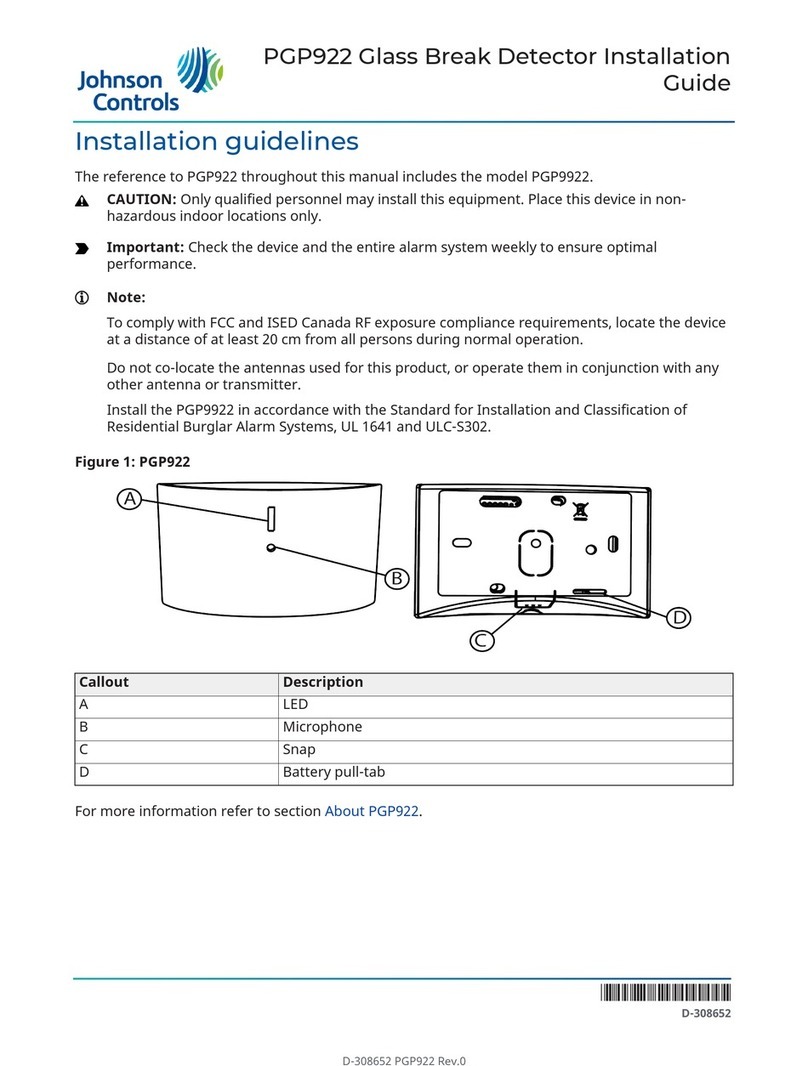

Johnson Controls PGP922 User manual

Johnson Controls

Johnson Controls LC-224 User manual

Johnson Controls

Johnson Controls PENN RLD-H10P Manual

Johnson Controls

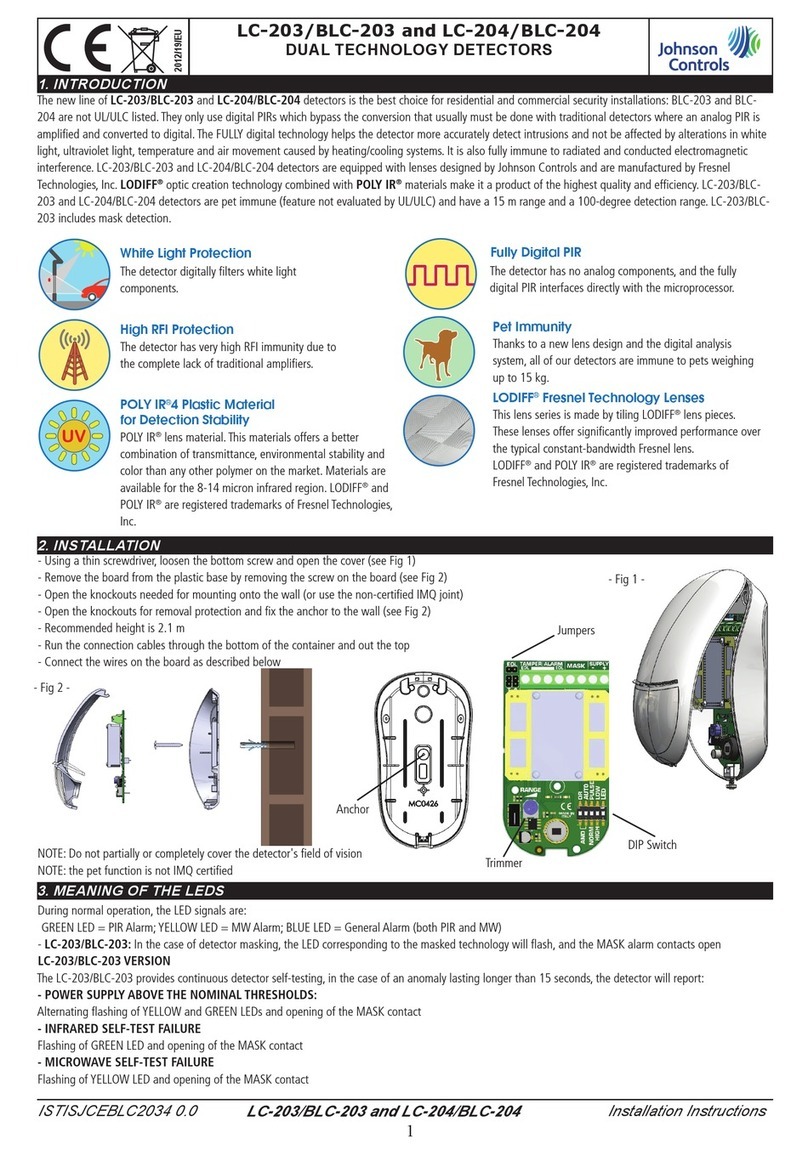

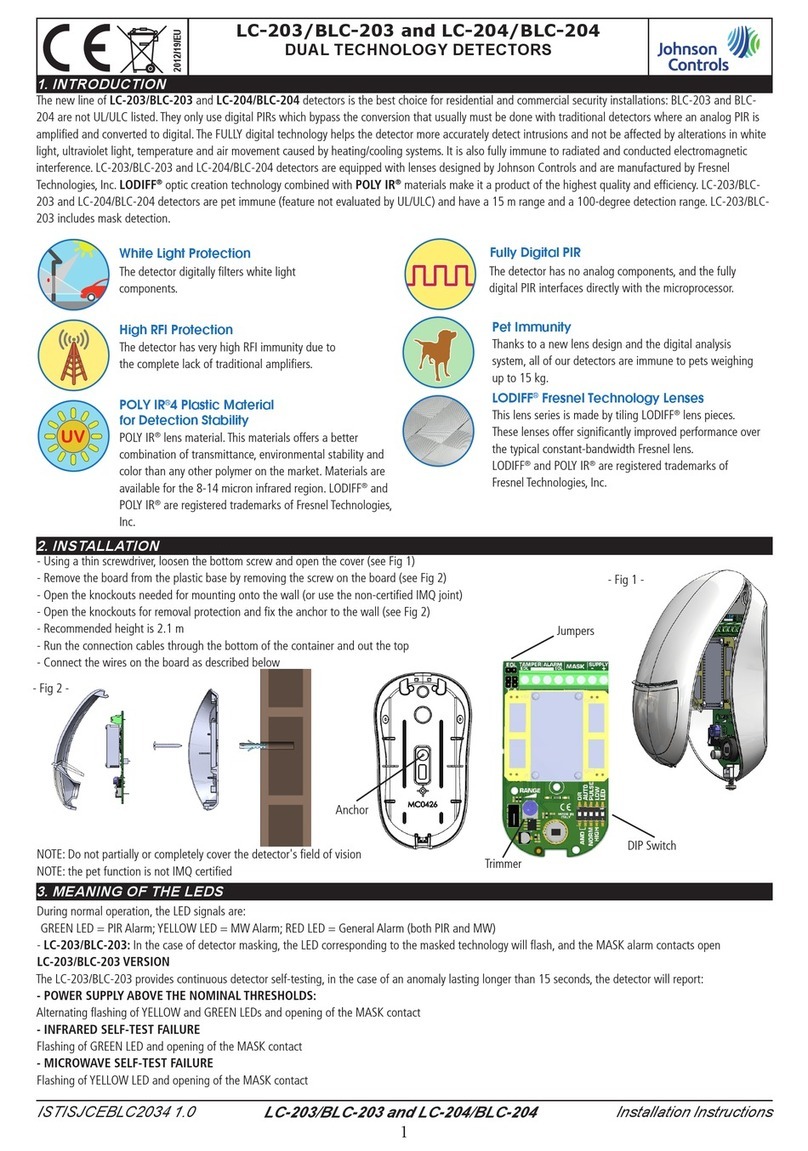

Johnson Controls LC-203 User manual

Johnson Controls

Johnson Controls PG9350SL User manual