www.jspsafety.com G-C-01083

_

20

-

12

technical@jspsafety.com | :+44 1993 826051

JSP Safety GmbH.

40549, DE

JSPLtd.

OX29 0TA , UK

Certied by: BSI Group The Netherlands B.V., (NB2797).

BSI Group The Netherlands B.V., John M. Keynesplein 9,

1066 EP Amsterdam, The Netherlands.

Copyright © 2006-2020. JSP Ltd. All Rights Reserved.

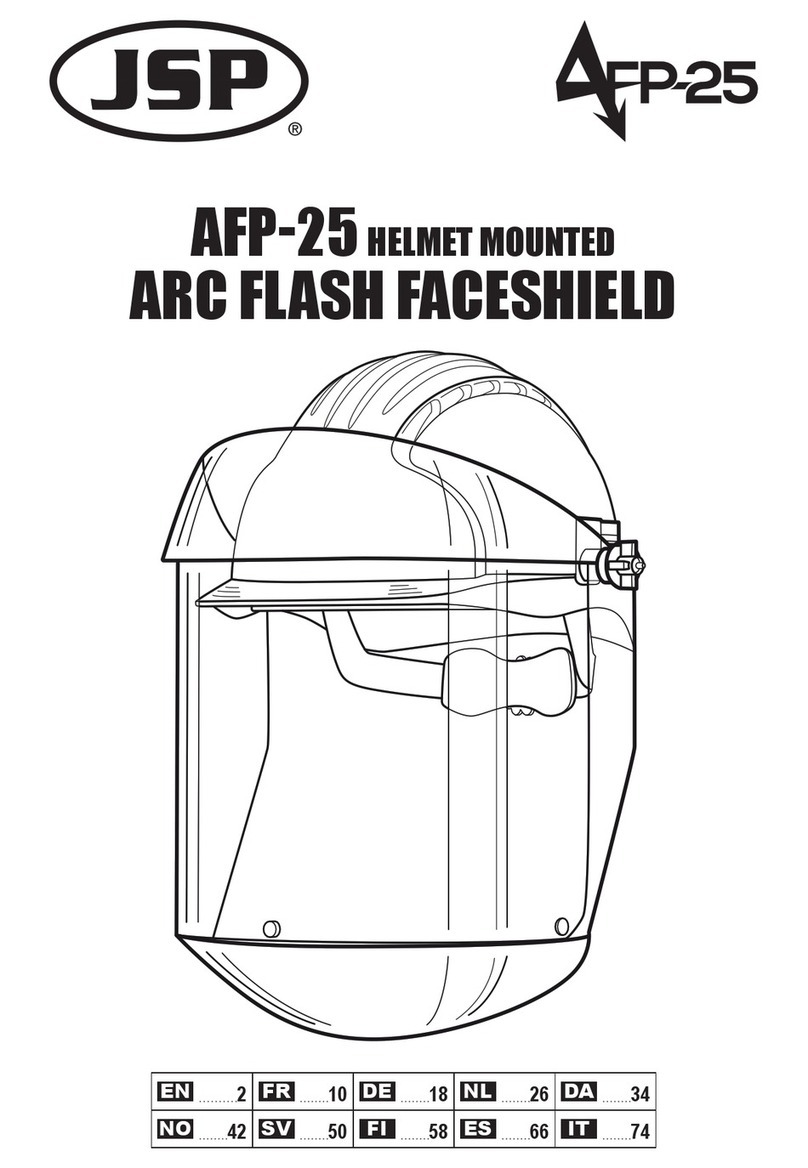

FITTING THE BROWGUARD ASSEMBLY

• Open out the head harness by pressing and rotating the knob on the back of the harness.

• To t the head harness, adjust the crown strap and the knob at the back of the head harness until the face seal ts around the face

when the visor is ipped down.

• The light duty breathing hose should run down the back of the user.

IN USE

• If an oil odour develops during use the quality of the supply air and any upstream in-line ltration should be checked to ensure that

the air being fed to the breathing equipment is free from oil mist. If tted, the regulator carbon cartridge may need replacing.

STORAGE

• The equipment should be stored in an uncontaminated environment away from direct sunlight preferably packed in an enclosure.

• Recommended limits of storage are 0 to +35°C with RH < 65%.

WARNINGS

• Breathable quality compressed air, as dened in EN132, MUST be available. Regulator lter is for nuisance odours only. It will NOT

lter particulates and hazardous vapours

• The user must ensure the purity and identity of the breathing air supply at all times.

• The air supply system should be equipped with an appropriately rated and adjusted pressure relief safety valve.

• If the face seal does not t closely to the face then the stated levels of protection may not be achieved.

• This system should not be used below 0°C.

• This system should not be used in or with oxygen or oxygen enriched air.

• At very high work rates the pressure in the visor may become negative at peak inhalation ow.

• The protection factor may not be achieved with persons with excessive facial hair or glasses.

• Adequate protection may not be provided by the apparatus in certain highly toxic atmospheres.

• This apparatus should not be used in areas where inhalation of the atmosphere, whilst escaping in the event of failure of the air

supply, would cause serious harm to health.

• The visor offers impact protection to EN166-F and optical class 1. These levels may be lowered if correct care is not taken of the

equipment. Optical clarity may be affected by contamination or by one or more visor covers.

CARE AND MAINTENANCE

All maintenance should be performed in an uncontaminated area.

• Visor covers (G-MVC10/G-MVC50) should be replaced when contaminated.

• The complete kit of equipment should be inspected on a monthly basis (or before use for occasional users) and any worn or

damaged components are replaced. Particular attention should be paid to the visor and its face seal.

• The equipment has a ve year shelf life from the date of manufacture.

• The equipment should be stored and transported in a way that will not affect its working performance. It should preferably be kept in

its original packing at an even ambient temperature and humidity.

CLEANING

• The external surfaces of all components may be cleaned using a sponge and warm soapy water and afterwards rinsed and allowed

to dry naturally.

• Do not immerse any part of the system in water, particularly the regulator system as this may damage it.

SPARE PARTS

Browguard Assembly G-N-AFB-A-BF Face Seal G-N-AF-FS

Visor Covers (pack of 10) G-MVC10 Breathing Tube G-N-AF-BT-BF

Visor Covers (pack of 50) G-MVC50 Nape Cover G-N-AF-NC

Visor G-N-AF-A170-BF Regulator Assembly and belt G-N-AF-W-R-CF-Y

Carbon Filter G-CC-CE