iv

%HVXUHWRWXUQWKHSRZHURIIDQGFKHFNWREHVXUHWKDWWKHPDFKLQHDQGPRWRUFRPSOHWHO\VWRSEHIRUHUH

PRYLQJWKHEHOWFRYHUDQG9EHOWLQRUGHUWRSUHYHQWDFFLGHQWFDXVHGE\DEUXSWVWDUWRIWKHPDFKLQHRUPRWRU

,IDVHUYRPRWRULVXVHGZLWKWKHPDFKLQHWKHPRWRUGRHVQRWSURGXFHQRLVHZKLOHWKHPDFKLQHLVDWUHVW

%HVXUHQRWWRIRUJHWWRWXUQWKHSRZHURIILQRUGHUWRSUHYHQWDFFLGHQWFDXVHGE\DEUXSWVWDUWRIWKHPRWRU

1HYHUXVHWKHPDFKLQHZLWKWKHFRROLQJRSHQLQJRIWKHPRWRUSRZHUER[VKLHOGHGLQRUGHUWRSUHYHQW¿UH

DFFLGHQWE\RYHUKHDW

/XEULFDWLRQ

%HVXUHWRXVH-8.,JHQXLQHRLODQG-8.,JHQXLQHJUHDVHWRWKHSDUWVWREHOXEULFDWHG

,IWKHRLODGKHUHVRQ\RXUH\HRUERG\EHVXUHWRLPPHGLDWHO\ZDVKLWRIILQRUGHUWRSUHYHQWLQÀDPPD

WLRQRULUULWDWLRQ

,IWKHRLOLVVZDOORZHGXQLQWHQWLRQDOO\EHVXUHWRLPPHGLDWHO\FRQVXOWDPHGLFDOGRFWRULQRUGHUWRSUH

YHQWGLDUUKHDRUYRPLWLQJ

0DLQWHQDQFH

,QSUHYHQWLRQRIDFFLGHQWFDXVHGE\XQIDPLOLDULW\ZLWKWKHPDFKLQHUHSDLUDQGDGMXVWPHQWKDVWREH

FDUULHGRXWE\DVHUYLFHWHFKQLFLDQZKRLVWKRURXJKO\IDPLOLDUZLWKWKHPDFKLQHZLWKLQWKHVFRSHGH¿QHG

LQWKHLQVWUXFWLRQPDQXDO%HVXUHWRXVH-8.,JHQXLQHSDUWVZKHQUHSODFLQJDQ\RIWKHPDFKLQHSDUWV

-8.,DVVXPHVQRUHVSRQVLELOLW\IRUDQ\DFFLGHQWFDXVHGE\LPSURSHUUHSDLURUDGMXVWPHQWRUWKHXVHRI

DQ\SDUWRWKHUWKDQ-8.,JHQXLQHRQH

,QSUHYHQWLRQRIDFFLGHQWFDXVHGE\XQIDPLOLDULW\ZLWKWKHPDFKLQHRUHOHFWULFDOVKRFNDFFLGHQWEHVXUH

WRDVNDQHOHFWULFDOWHFKQLFLDQRI\RXUFRPSDQ\RU-8.,RUGLVWULEXWRULQ\RXUDUHDIRUUHSDLUDQGPDLQWH

QDQFHLQFOXGLQJZLULQJRIHOHFWULFDOFRPSRQHQWV

:KHQFDUU\LQJRXWUHSDLURUPDLQWHQDQFHRIWKHPDFKLQHZKLFKXVHVDLUGULYHQSDUWVVXFKDVDQDLUF\O

LQGHUEHVXUHWRUHPRYHWKHDLUVXSSO\SLSHWRH[SHODLUUHPDLQLQJLQWKHPDFKLQHEHIRUHKDQGLQRUGHUWR

SUHYHQWDFFLGHQWFDXVHGE\DEUXSWVWDUWRIWKHDLUGULYHQSDUWV

%HVXUHWRFKHFNWKDWVFUHZVDQGQXWVDUHIUHHIURPORRVHQHVVDIWHUFRPSOHWLRQRIUHSDLUDGMXVWPHQW

DQGSDUWUHSODFHPHQW

%HVXUHWRSHULRGLFDOO\FOHDQXSWKHPDFKLQHGXULQJLWVGXUDWLRQRIXVH%HVXUHWRWXUQWKHSRZHURII

DQGYHULI\WKDWWKHPDFKLQHDQGPRWRUVWRSFRPSOHWHO\EHIRUHFOHDQLQJWKHPDFKLQHLQRUGHUWRSUHYHQW

DFFLGHQWFDXVHGE\DEUXSWVWDUWRIWKHPDFKLQHRUPRWRU

%HVXUHWRWXUQWKHSRZHURIIDQGYHULI\WKDWWKHPDFKLQHDQGPRWRUVWRSFRPSOHWHO\EHIRUHFDUU\LQJRXW

PDLQWHQDQFHLQVSHFWLRQRUUHSDLURIWKHPDFKLQH)RUWKHPDFKLQHZLWKDFOXWFKPRWRUWKHPRWRUZLOO

NHHSUXQQLQJIRUDZKLOHE\LQHUWLDHYHQDIWHUWXUQLQJWKHSRZHURII6REHFDUHIXO

,IWKHPDFKLQHFDQQRWEHQRUPDOO\RSHUDWHGDIWHUUHSDLURUDGMXVWPHQWLPPHGLDWHO\VWRSRSHUDWLRQDQG

FRQWDFW-8.,RUWKHGLVWULEXWRULQ\RXUDUHDIRUUHSDLULQRUGHUWRSUHYHQWDFFLGHQWWKDWFDQUHVXOWLQSHU

VRQDOLQMXU\RUGHDWK

,IWKHIXVHKDVEORZQEHVXUHWRWXUQWKHSRZHURIIDQGHOLPLQDWHWKHFDXVHRIEORZLQJRIWKHIXVHDQG

UHSODFHWKHEORZQIXVHZLWKDQHZRQHLQRUGHUWRSUHYHQWDFFLGHQWWKDWFDQUHVXOWLQSHUVRQDOLQMXU\RU

GHDWK

%HVXUHWRSHULRGLFDOO\FOHDQXSWKHDLUYHQWRIWKHIDQDQGLQVSHFWWKHDUHDDURXQGWKHZLULQJLQRUGHUWR

SUHYHQW¿UHDFFLGHQWRIWKHPRWRU

2SHUDWLQJHQYLURQPHQW

%HVXUHWRXVHWKHPDFKLQHXQGHUWKHHQYLURQPHQWZKLFKLVQRWDIIHFWHGE\VWURQJQRLVHVRXUFHHOHFWUR

PDJQHWLFZDYHVVXFKDVDKLJKIUHTXHQF\ZHOGHULQRUGHUWRSUHYHQWDFFLGHQWFDXVHGE\PDOIXQFWLRQRI

WKHPDFKLQH

1HYHURSHUDWHWKHPDFKLQHLQDQ\SODFHZKHUHWKHYROWDJHÀXFWXDWHVE\PRUHWKDQUDWHGYROWDJH

LQRUGHUWRSUHYHQWDFFLGHQWFDXVHGE\PDOIXQFWLRQRIWKHPDFKLQH

%HVXUHWRYHULI\WKDWWKHDLUGULYHQGHYLFHVXFKDVDQDLUF\OLQGHURSHUDWHVDWWKHVSHFL¿HGDLUSUHVVXUH

EHIRUHXVLQJLWLQRUGHUWRSUHYHQWDFFLGHQWFDXVHGE\PDOIXQFWLRQRIWKHPDFKLQH

7RXVHWKHPDFKLQHZLWKVDIHW\EHVXUHWRXVHLWXQGHUWKHHQYLURQPHQWZKLFKVDWLV¿HVWKHIROORZLQJ

FRQGLWLRQV

$PELHQWWHPSHUDWXUHGXULQJRSHUDWLRQ &WR&

5HODWLYHKXPLGLW\GXULQJRSHUDWLRQ WR

'HZFRQGHQVDWLRQFDQRFFXULIEULQJLQJWKHPDFKLQHVXGGHQO\IURPDFROGHQYLURQPHQWWRDZDUPRQH

6REHVXUHWRWXUQWKHSRZHURQDIWHUKDYLQJZDLWHGIRUDVXI¿FLHQWSHULRGRIWLPHXQWLOWKHUHLVQRVLJQ

RIZDWHUGURSOHWLQRUGHUWRSUHYHQWDFFLGHQWFDXVHGE\EUHDNDJHRUPDOIXQFWLRQRIWKHHOHFWULFDOFRPSR

QHQWV

%HVXUHWRVWRSRSHUDWLRQZKHQOLJKWQLQJÀDVKHVIRUWKHVDNHRIVDIHW\DQGUHPRYHWKHSRZHUSOXJLQ

RUGHUWRSUHYHQWDFFLGHQWFDXVHGE\EUHDNDJHRUPDOIXQFWLRQRIWKHHOHFWULFDOFRPSRQHQWV

'HSHQGLQJRQWKHUDGLRZDYHVLJQDOFRQGLWLRQWKHPDFKLQHPD\JHQHUDWHQRLVHLQWKH79RUUDGLR,IWKLV

RFFXUVXVHWKH79RUUDGLRZLWKNHSWZHOODZD\IURPWKHPDFKLQH

,QRUGHUWRHQVXUHWKHZRUNHQYLURQPHQWORFDOODZVDQGUHJXODWLRQVLQWKHFRXQWU\ZKHUHWKHVHZLQJ

PDFKLQHLVLQVWDOOHGVKDOOEHIROORZHG

,QWKHFDVHWKHQRLVHFRQWUROLVQHFHVVDU\DQHDUSURWHFWRURURWKHUSURWHFWLYHJHDUVKRXOGEHZRUQDF

FRUGLQJWRWKHDSSOLFDEOHODZVDQGUHJXODWLRQV

'LVSRVDORISURGXFWVDQGSDFNDJHVDQGWUHDWPHQWRIXVHGOXEULFDWLQJRLOVKRXOGEHFDUULHGRXWSURSHUO\

DFFRUGLQJWRWKHUHOHYDQWODZVRIWKHFRXQWU\LQZKLFKWKHVHZLQJPDFKLQHLVXVHG

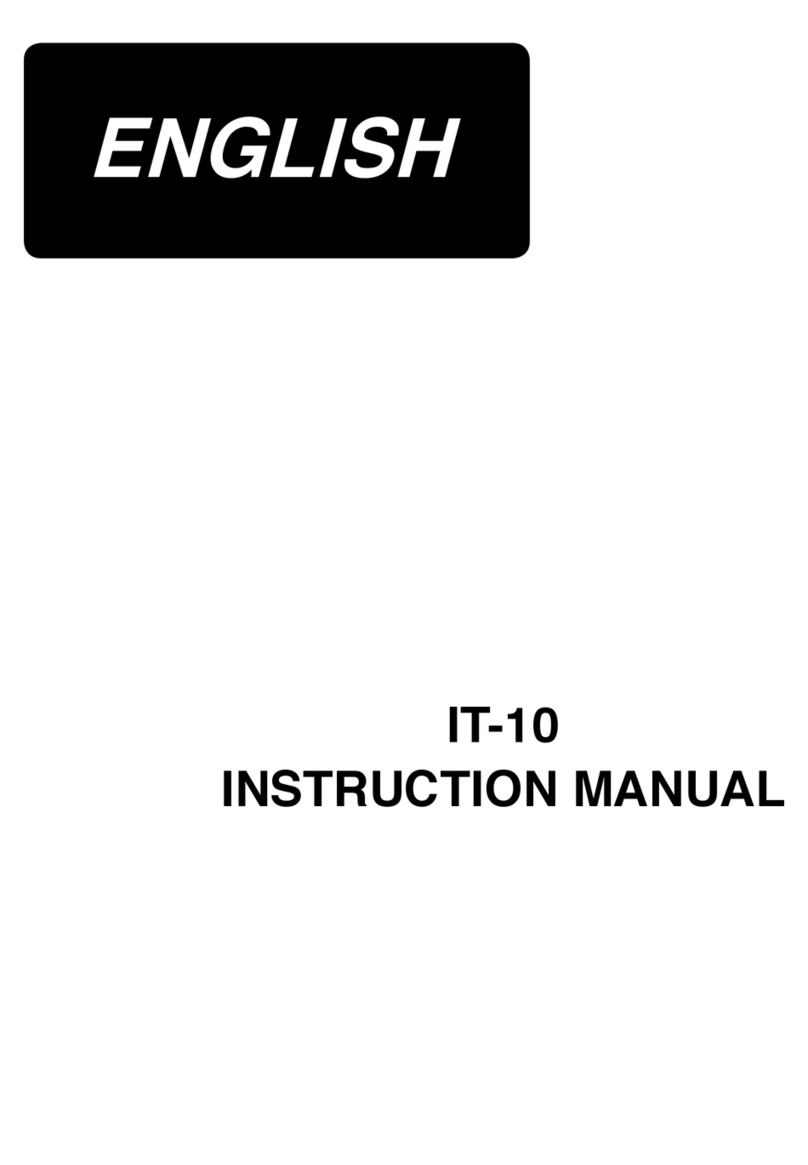

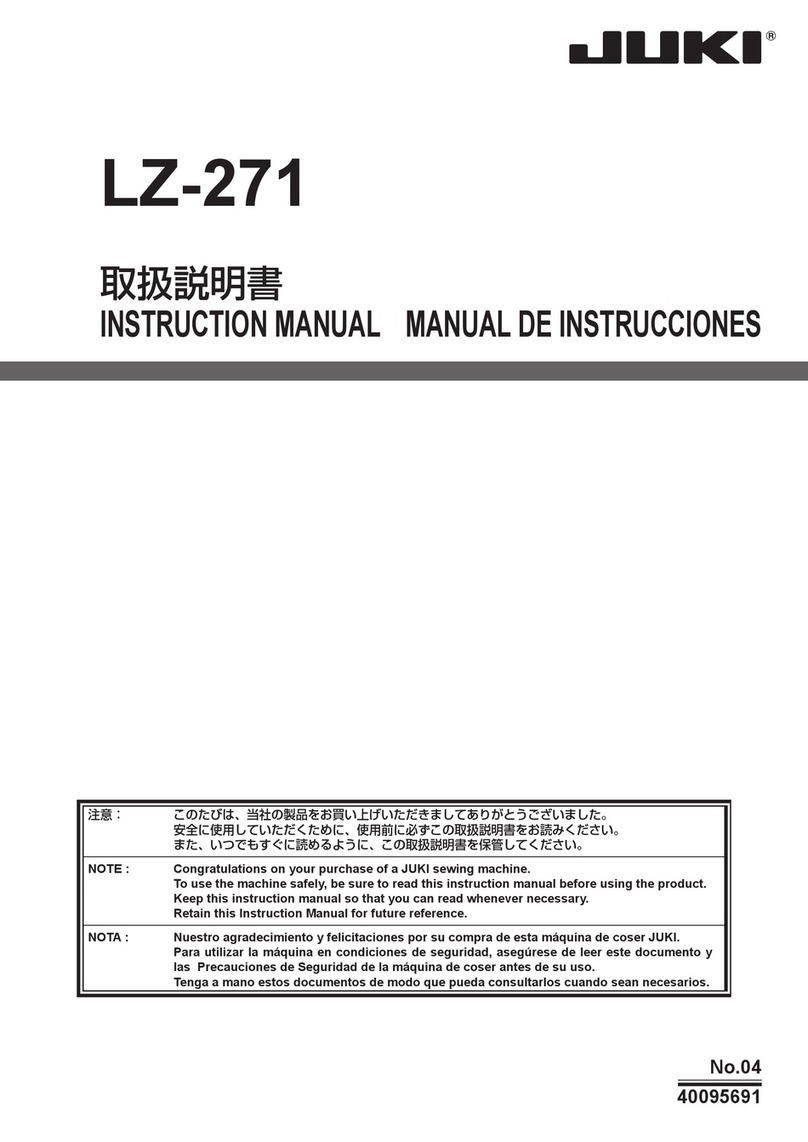

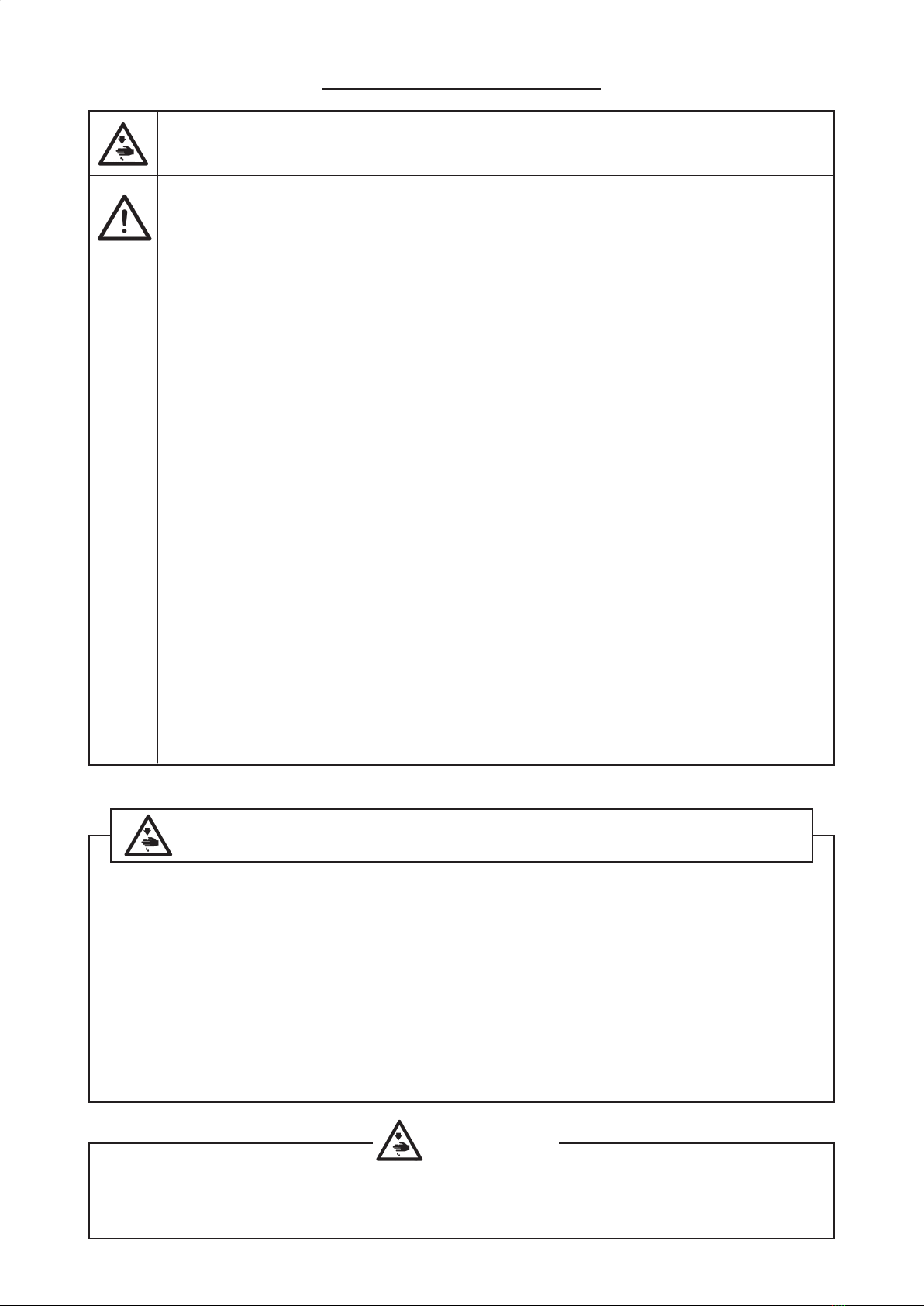

1

2

3

4

5

A

B

0.8 - 1.2 mm

4

5

1

2

0.4 - 1.0 mm

2

C

4

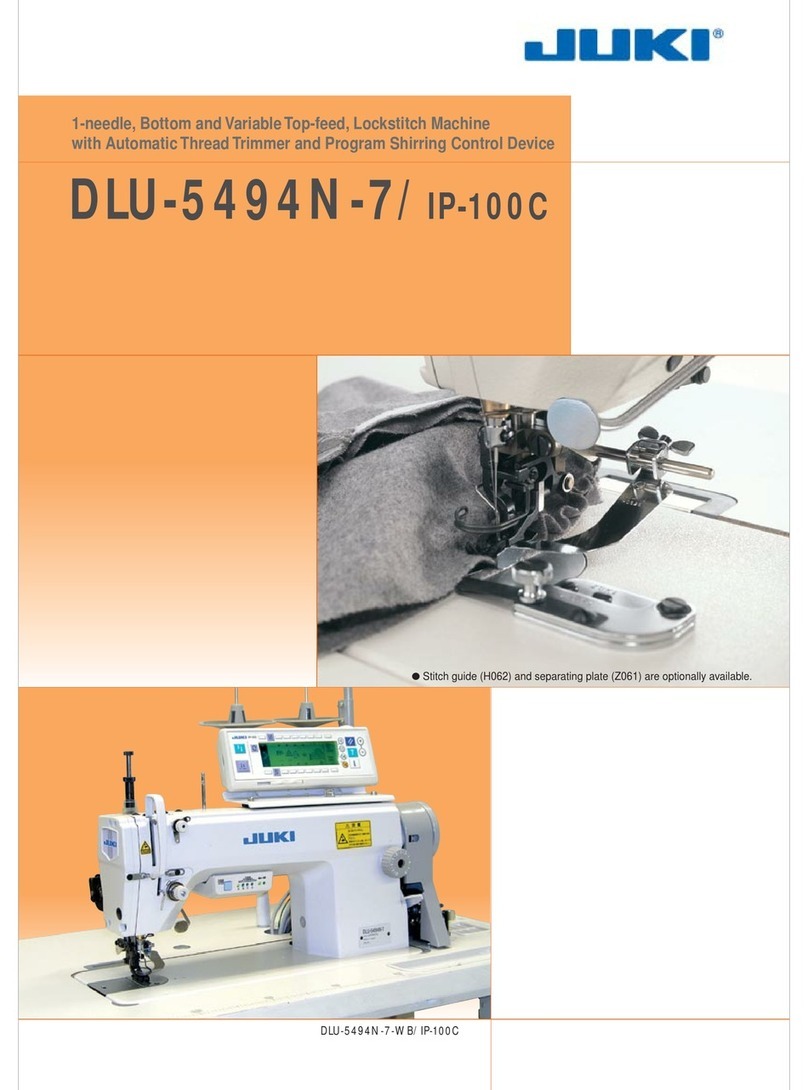

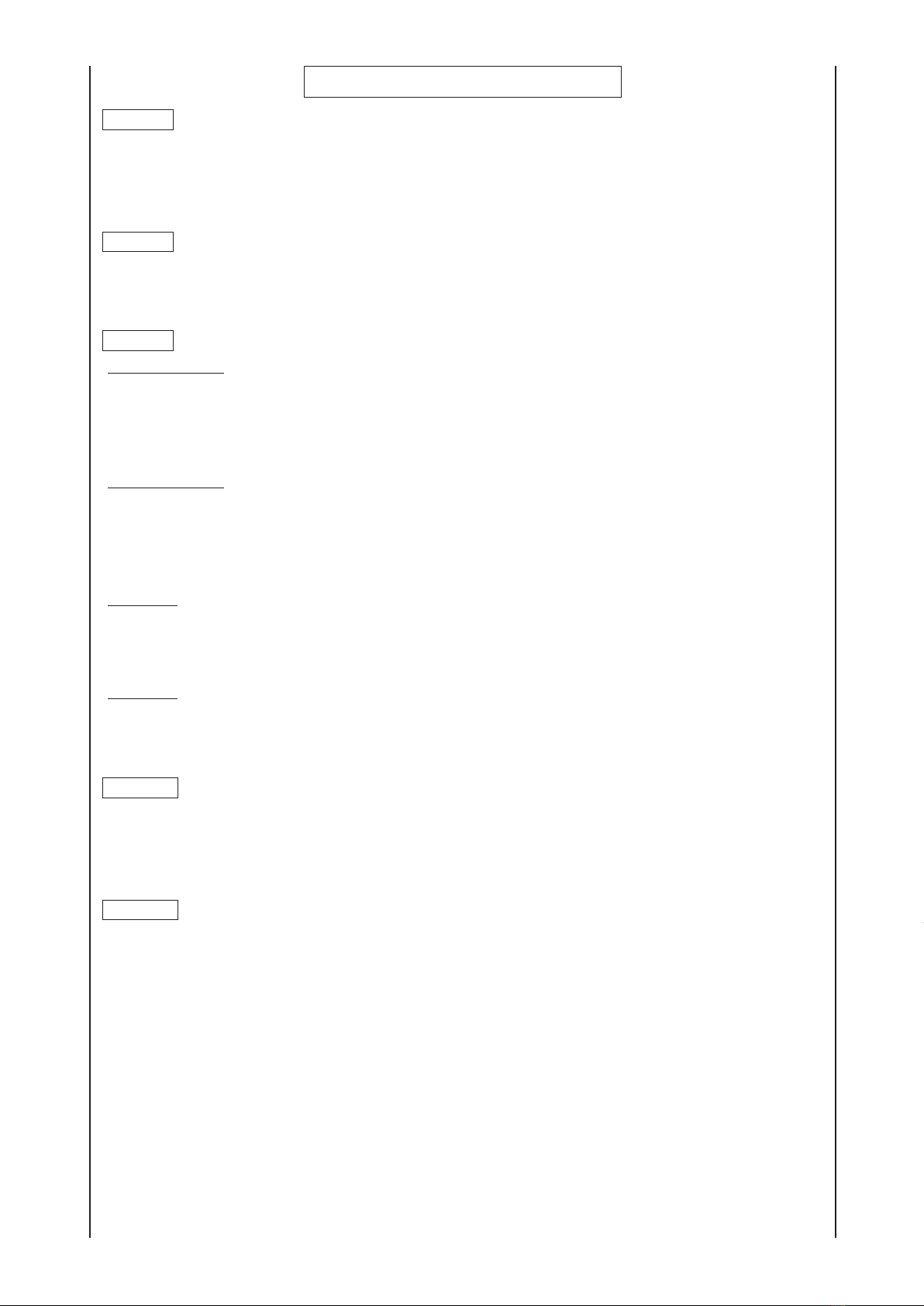

14. Adjusting the spreader thread guide and the needle clamp thread guide /

分布导线器、针夹导线器的调整

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

注意 :

为了防止突然起动造成人身事故,请关掉电源,确认马达确实停止转动后再进行操作。

[Spreader thread guide]

Adjust so that the clearance between spreader thread

guide 2and spreader 1is0.4to1.0mm.Thenxthe

spreader thread guide with setscrews 3.

* Adjust so that the center of slot Aof spreader thread

guide 2aligns with blade point Bof spreader 1when

spreader 1is in the extreme right position. In addition,

allow the spreader thread guide 2to come near the

needle clamp to such an extent that the spreader

thread guide does not interfere with the needle clamp.

[Needle clamp thread guide]

Adjust so that the center of thread hole of needle clamp

thread guide 4aligns with center Cof slot Awhen the

needle is in the lowest position.

* At this time, adjust so that the clearance between

needle clamp thread guide 4and spreader thread

guide 2is0.8to1.2mm.Thenxtheneedleclamp

thread guide with setscrew 5.

[分布导线器]

把分布导线器 2和分布器 1的间隙调整为 0.4 〜 1.0mm,

然后用固定螺丝 3进行固定。

※ 分布器 1在最右点时,请把分布器 1的尖部 B调

整到与分布导线器 2的长槽 A 的中心一致。另外,

分线导线器 2应不与针座相碰而尽量靠近。

[针夹导线器]

机针在最下点时,请把针夹导线器 4的线孔中心和分布

导线器 2的长槽 A的中心 C调整成一致。

※ 此时,请把针夹导线器 4和分布导线器 2的间隙

调整为 0.8 〜 1.2mm,然后用固定螺丝 5进行固定。