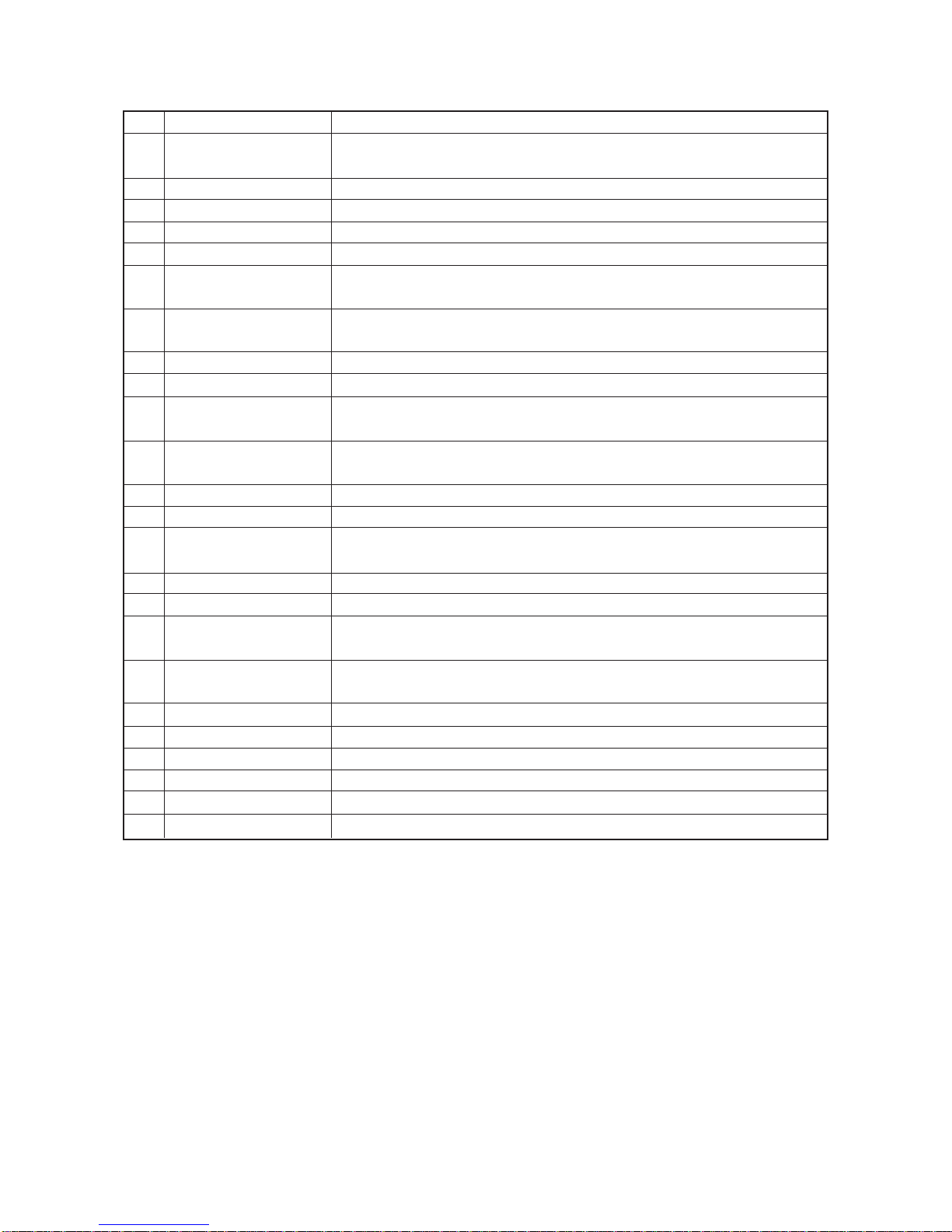

CONTENTS

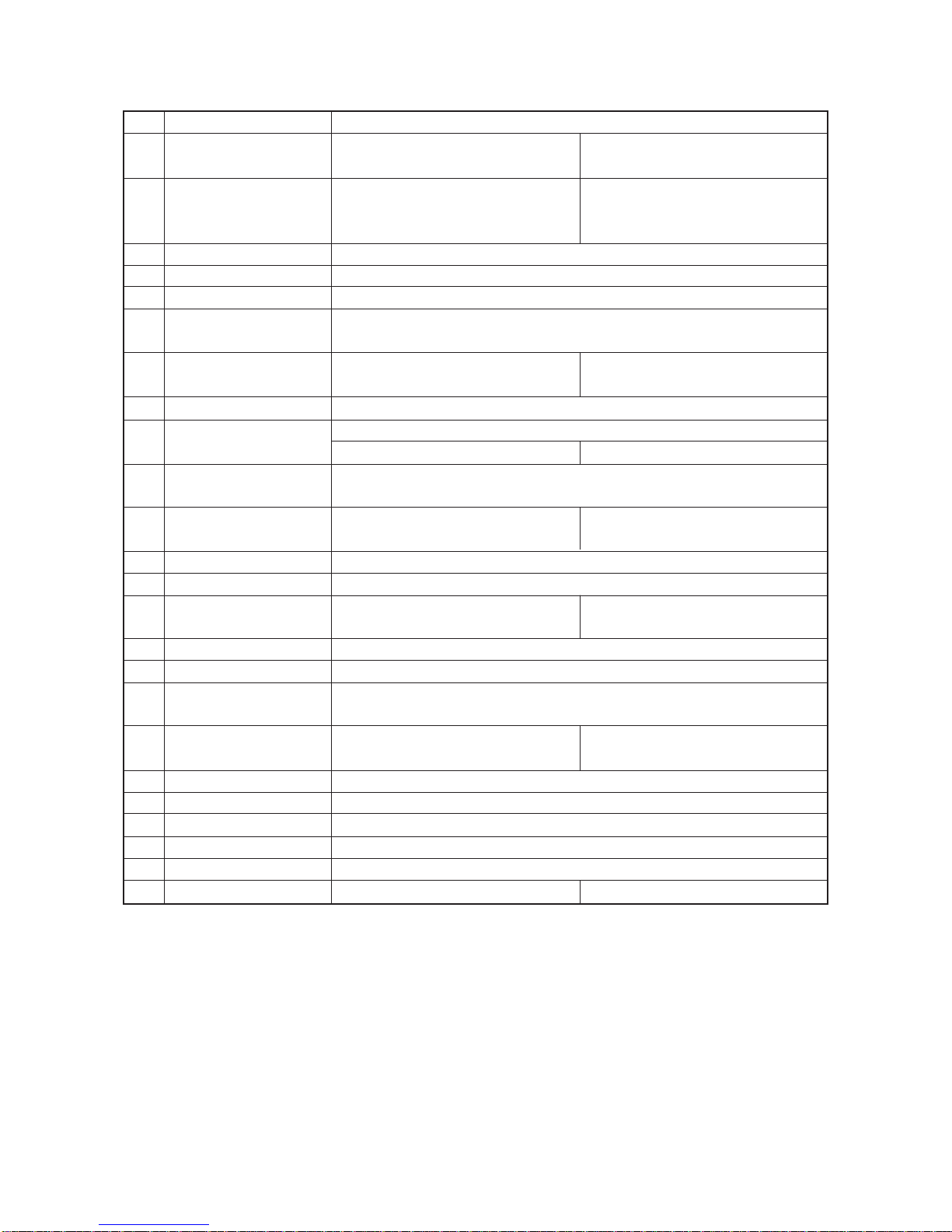

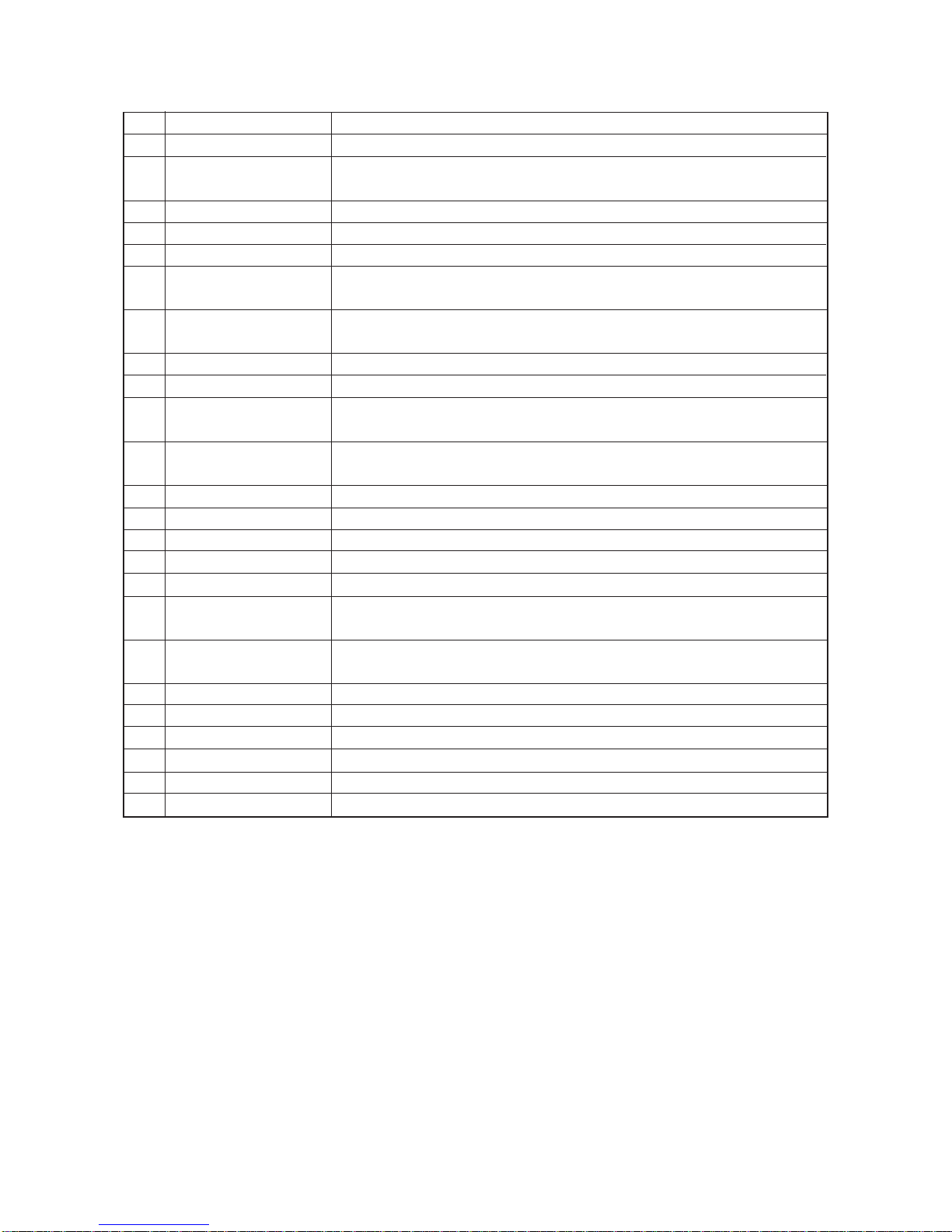

1. SPECIFICATIONS.................................................................................................. 1

2. STANDARD ADJUSTMENT ................................................................................... 6

(1) Needle entry position ............................................................................................................. 6

(2) Longitudinal position of the feed dog ..................................................................................... 6

(3) Lateral position of the feed dog .............................................................................................. 8

(4) Height of the feed dog ............................................................................................................ 8

(5) Height of the hook .................................................................................................................10

(6) Adjusting the inner hook guide .............................................................................................10

(7) Needle-to-hook timing ...........................................................................................................12

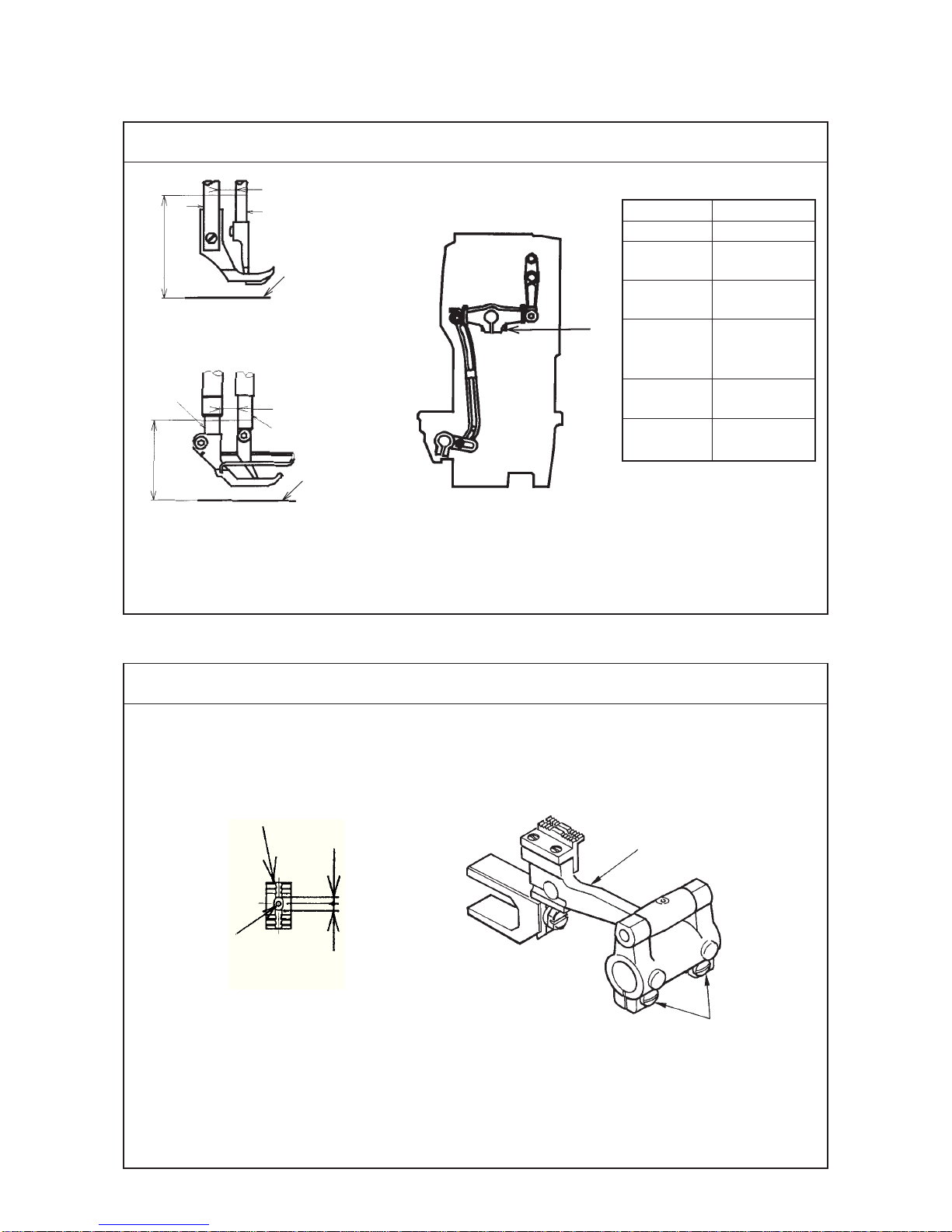

(8) Lift of the presser foot ...........................................................................................................14

1) Hand lifter......................................................................................................................................................... 14

2) Knee lifter (Without thread trimmer only) ............................................................................................................. 14

3) Automatic presser foot lifter (Machine with thread trimmer only) ............................................................................ 16

(9) Timing between the upper shaft and the lower shaft .............................................................16

(10) Feed cam timing..................................................................................................................18

1) Horizontal feed cam timing ................................................................................................................................18

2) Top feed cam timing ......................................................................................................................................... 20

(11) Feed motion ........................................................................................................................22

1) Amount of alternate vertical movement (position of the vertical adjusting arm)........................................................ 22

2) Alternate momentum ........................................................................................................................................ 24

(12) Needle sway (Adjusting the bottom feed amount) ...............................................................24

(13) Stitch length of normal/reverse feed ....................................................................................26

(14) Balancer (Machine without thread trimmer only) .................................................................26

(15) Vertical position of the needle bar rocking frame .................................................................28

(16) Dimension of the needle stop adjusting slide shaft (asm.) ...................................................30

(17) Position of the change lever ................................................................................................30

(18) Position of the reverse feed control lever.............................................................................32

(19) Safety clutch .......................................................................................................................32

(20) Reverse feed cylinder ..........................................................................................................34

(21) Lubrication ..........................................................................................................................34

1) In case of manual lubrication ......................................................................................................................... 34

2) In case of automatic lubrication...................................................................................................................... 36

(22) Thread trimmer device ........................................................................................................38

1) Position of the counter knife and the clamp spring ............................................................................................... 38

2) Position of the counter knife base ....................................................................................................................... 40

3) Vertical position of the moving knife .................................................................................................................... 40

4) Adjusting the knife pressure ............................................................................................................................... 42

5) Thread trimmer cam ......................................................................................................................................... 42

6) Thread trimmer cam timing ................................................................................................................................44

7) Connecting the rocking arm and the thread trimmer roller arm .............................................................................. 44

8) Connecting the left and right rocking arms (2-needle machine only) ...................................................................... 46

9) Thread trimmer solenoid.................................................................................................................................... 46

(23) Alternate vertical dial ...........................................................................................................48

1) Installing position of the detection switch of the amount of alternate vertical movement ........................................... 48