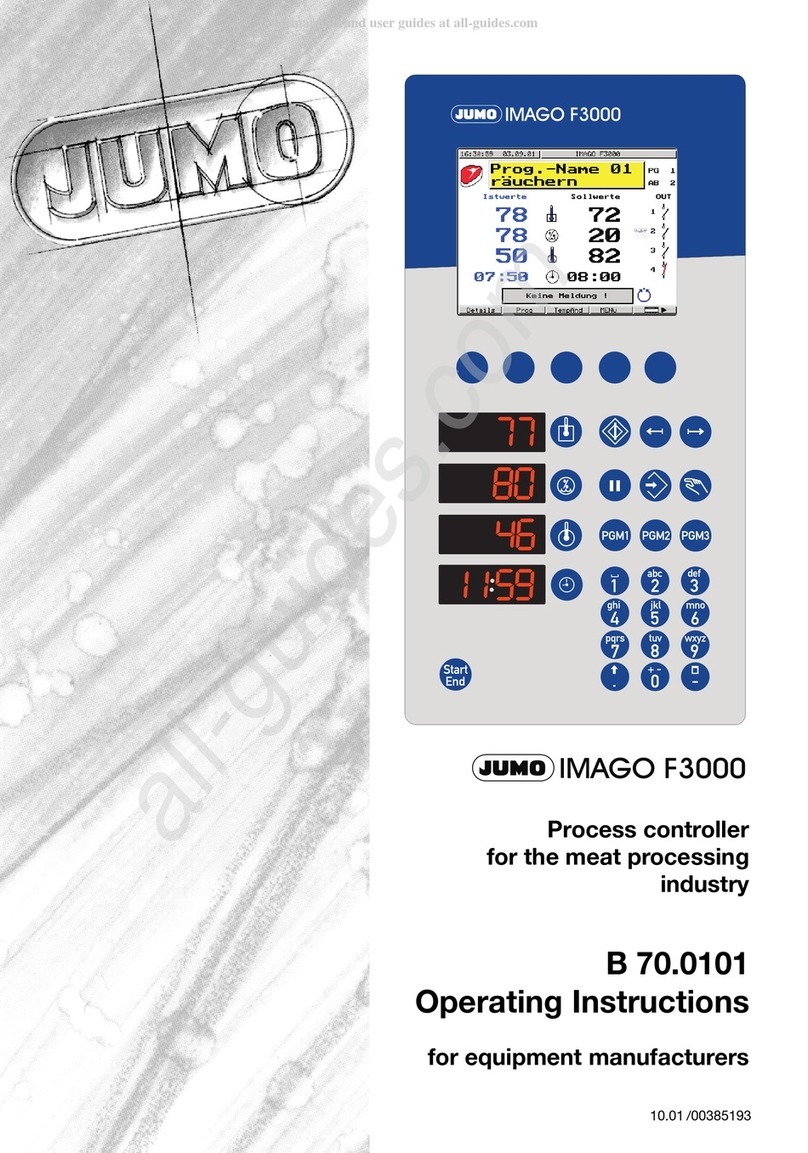

IMAGO F3000 / 10.01

Contents

6.10.3 Smoke generator ................................................................................................. 45

6.10.4 Self-optimization .................................................................................................. 45

6.10.5 Password (parameter) .......................................................................................... 45

6.11 User data ............................................................................................................... 46

6.11.1 Contrast ............................................................................................................... 46

6.11.2 Display ................................................................................................................. 46

6.11.3 Instrument data ................................................................................................... 46

6.12 MENU counter ...................................................................................................... 46

6.13 MENU instrument access .................................................................................... 46

6.14 Plug & Play (P&P) .................................................................................................. 47

6.14.1 Write data to P&P memory .................................................................................. 49

6.14.2 Activate automatic save ...................................................................................... 49

6.14.3 Activate/de-activate write protection .................................................................. 50

6.14.4 Copying programs ............................................................................................... 52

6.14.5 Replacing a faulty instrument .............................................................................. 53

6.14.6 Retrofitting a P&P memory .................................................................................. 54

6.14.7 Making a backup copy ........................................................................................ 54

6.14.8 Commissioning a new instrument ....................................................................... 54

6.14.9 P&P memory, programming by OEM .................................................................. 54

6.14.10 Loading data for a write-protected P&P memory on site .................................... 54

6.14.11 Load new instrument software ............................................................................ 55

6.15 Instrument-only settings ..................................................................................... 56

7SetupProgram 57

7.1 Selectors ............................................................................................................... 58

7.2 Process steps ....................................................................................................... 60

7.2.1 List of the process steps ..................................................................................... 60

7.2.2 Editing process steps .......................................................................................... 61

7.3 Screen representation ......................................................................................... 63

7.4 Configuration ........................................................................................................ 63

7.4.1 Interfaces ............................................................................................................. 63

7.4.2 Special settings in interface operation with mTRON modules ............................ 63

7.4.3 Analog inputs ....................................................................................................... 64

7.4.4 Controller ............................................................................................................. 65

7.4.5 Core changeover ................................................................................................. 67

7.4.6 Program source ................................................................................................... 68

7.5 Parameterization .................................................................................................. 70