- 2 -

CONTENTS

Page No:

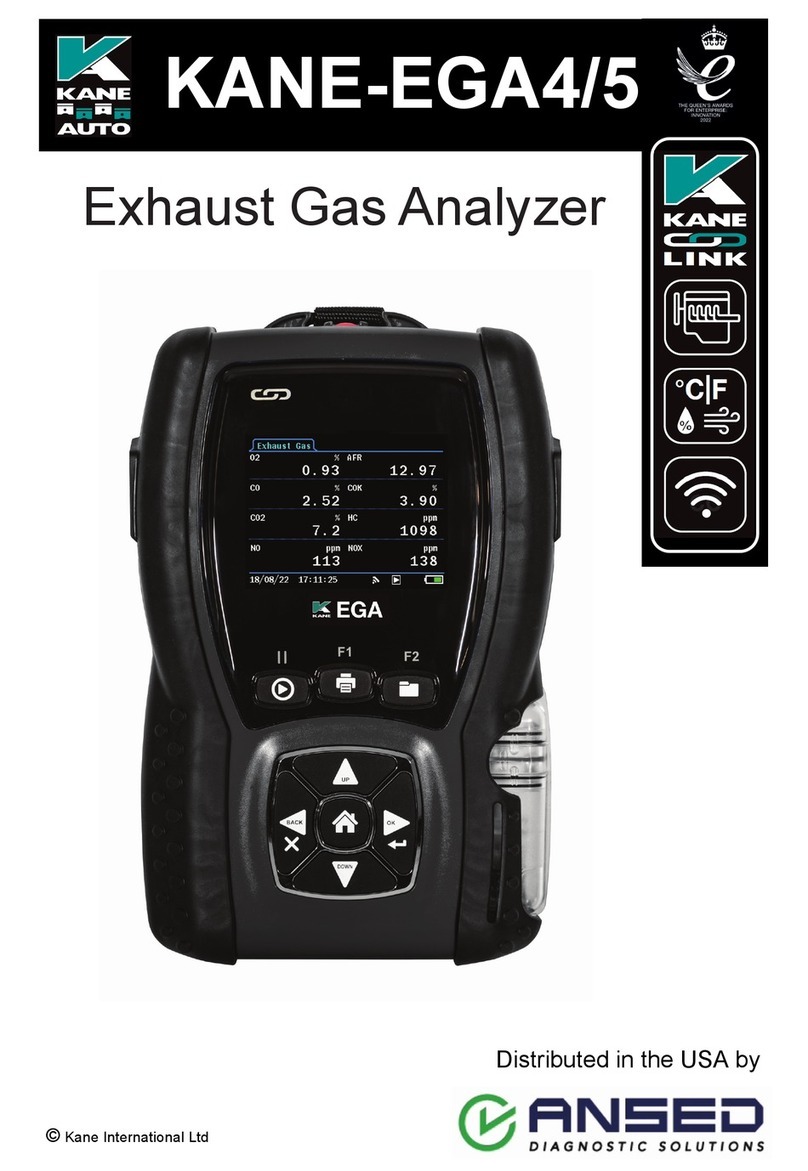

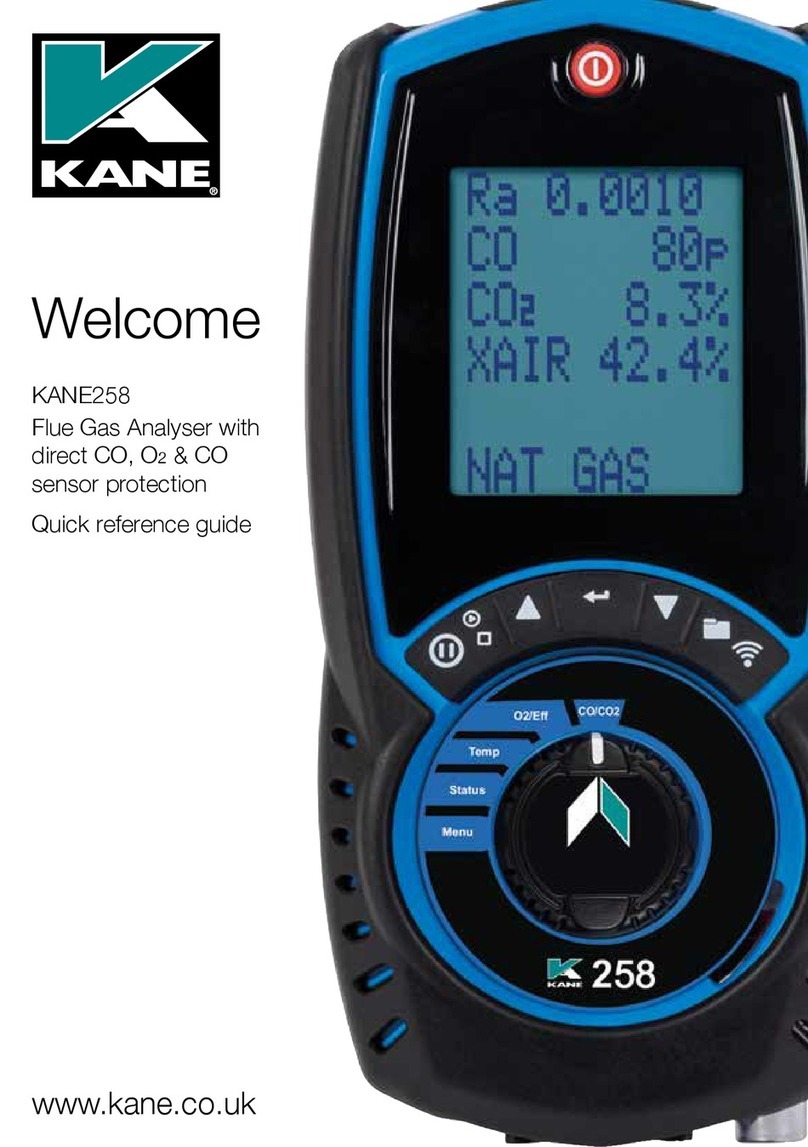

1. ANALYSER LAYOUT AND FEATURES............................................................ 4-7

1.1 Instrument features and keypad...........................................................................4

1.2 Instrument layout (Rear) .....................................................................................5

1.3 Standard Probe Configuration.............................................................................6

1.4 Analyser connections ..........................................................................................7

2. SAFETY WARNING ...................................................................................................8

3. FIRST TIME USE ........................................................................................................8

4. NORMAL START UP SEQUENCE...................................................................... 9-15

4.1 Every Time You Use The Analyser ....................................................................9

4.2 Automatic Calibration .........................................................................................9

4.3 Main Display Parameters ..................................................................................11

4.3.1 4 Page Mode.........................................................................................11

4.3.2 Line Scroll Mode..................................................................................12

4.3.3 8 Page Mode.........................................................................................12

4.4 Sampling the Flue Gas ......................................................................................13

4.5 Taking a Pressure Reading................................................................................13

4.6 Regular Checks During Sampling.....................................................................14

4.7 Normal Shutdown Sequence .............................................................................14

4.8 Electromagnetic Compatibility .........................................................................15

5. MOVING THROUGH THE MENUS.................................................................. 16-22

5.1 Basic Operation .................................................................................................16

5.2 Menu Options and Settings ...............................................................................17

5.2.1 Main Menu ............................................................................................17

5.2.2 Select Menu ..........................................................................................17

5.2.3 Units Menu ............................................................................................19

5.2.4 Display Menu ........................................................................................20

5.2.5 Set-Up Menu .........................................................................................20

6. PRINTING INFORMATION.....................................................................................23

6.1 Printing a ‘Live’ Test..........................................................................................23

6.2 Standard Printout ................................................................................................23

7. STORING AND RETRIEVING DATA .............................................................. 24-25

7.1 Storing a ‘Live’ Test .........................................................................................24

7.2 Viewing and Printing a ‘Stored’ Test................................................................24

7.3 Deleting Data.....................................................................................................25