English KM 100/40 W 4

FOR YOUR SAFETY!

General instructions

It is mandatory to read and

observe this prior to usin the

appliance!

♦

Notify your sales outlet if during

unpacking you detect damage that

has occurred in transit.

♦

Read the operating instructions of

your appliance prior to putting it into

operation, especially the safety

information.

♦

The danger and caution signs

attached to the appliance give

important tips on its safe operation.

♦

In addition to the instructions in the

operating instructions, general

safety- and accident

prevention-regulations from

lawgivers must be followed.

Use

♦

Prior to utilization the appliance and

its working facilities must be

checked regarding their proper

condition and that they operate

safely. It must not be used if its

condition is not faultless.

♦

No modifications permitted on the

machine.

♦

Never absorb e plosive liquids,

inflammable gases or undiluted

acids and solvents! This includes

petrol, paint thinner or fuel oil,

which can form e plosive fumes

due to the swirling suction air, in

addition acetone, undiluted acids

and solvents, since they corrode

the materials used for the

appliance.

♦

Do not sweep up/absorb burning or

smouldering objects.

♦

Only if e pressely marked is this

appliance suitable for sucking up

health-hazardous dusts. Comply

with notices concerning safety

regulations given in the operating

instructions.

♦

Suitable only for the surfaces listed

in the operating instructions.

♦

The appliance may be used on only

the areas cleared for its use by the

factory owner or a person

authorized by him.

♦

Keep clear of the danger area. Its

operation in e plosion hazardous

locations is prohibited.

♦

The following applies generally:

Keep combustible materials away

from the machine (danger of

e plosions-/fire).

Operation

♦

The rules, regulations and

stipulations applying to motor

vehicles must always be observed.

♦

The operator must use the unit in

accordance with its intended

purpose. She must adapt her mode

of operation to the local conditions

and when working with the

appliance keep a look out for third

parties, especially children.

♦

The appliance may only be used by

persons instructed in its handling or

who have proved their capability of

operating it and who are e pressely

authorized to use it.

♦

The unit must not be operated by

children and youths.

♦

To prevent unauthorized utilization

of appliances provided with an

ignition key the ignition key must be

removed.

♦

The appliance must never be left

unattended as long as the motor is

running. The operator may not

leave the appliance until the motor

is turned off, the appliance is

safeguarded against unintentional

motion, if necessary the parking

brake actuated and the ignition key

removed.

♦

On slopes the angle of inclination to

the side and in the direction of

motion must not e ceed the value

given in the operating instructions.

Transport

♦

The motor must be turned off when

the appliance is transported.

♦

To lock the parking brake.

♦

To secure the machine with tension

belts, ropes or chains.

♦

To secure the machine at the

wheels with wedges.

Maintenance

♦

Repairs may only be carried out by

approved customer service centres

or by technical personnel trained in

this field which are familiar with all

relevant safety regulations.

♦

Industrially used appliances in

changing locations are subject to

the safety inspection according to

VDE 0701.

♦

Prior to beginning work on the

electrical equipment of battery-

driven units the battery plug

connection must be unplugged or

the battery disconnected and the

battery must be disconnected in the

case of combustion engine driven

units.

♦

The unit must be switched off and,

if necessary, the ignition key

removed prior to cleaning it,

performing maintenance work on it,

replacing parts or resetting it to a

different operation.

♦

Unless e pressly permitted the unit

may not be cleaned with hose or

high-pressure water jets. (Danger

of short circuits or other

impairments).

Accessories and spare parts

♦

Only accessories and spare parts

cleared by the manufacturer may

be used. Genuine accessories and

spare parts guarantee that the

appliance can be operated safely

and trouble-free.

Battery driven appliances

♦

Warranty is valid only when you

use the batteries and charging units

recommended by Kärcher.

♦

It is mandatory to comply with the

battery manufacturer's operating

instructions. Heed the legislative

recommendations on handling of

batteries.

♦

Never leave a battery in a run down

condition but recharge it as soon as

possible.

♦

Keep the batteries always clean

and dry to prevent leaking currents.

Protect from contamination, e.g.. by

metallic powder.

♦

No tools and similar objects. to be

placed on the battery. Hazard of

short circuits and e plosion.

♦

Do not under any circumstances

work with an open flame, create

sparks or smoke near a battery or

in a battery recharging room.

E plosion hazard.

♦

Do not touch hot parts, e.g. drive

motor (danger of burns).

♦

Take care when handling

accumulator acid. Heed the

relevant safety regulations!

♦

Used batteries are to be disposed

of in an environmentally friendly

way, according to

EC-guideline 91/157 EWG.

Tip hazard if slope too steep!

♦

The machine could topple over

when driving and turning on slopes.

♦

In direction of travel only negotiate

gradients up to 15 %

♦

At right angles to direction of travel

only negotiate gradients up to

15 %.

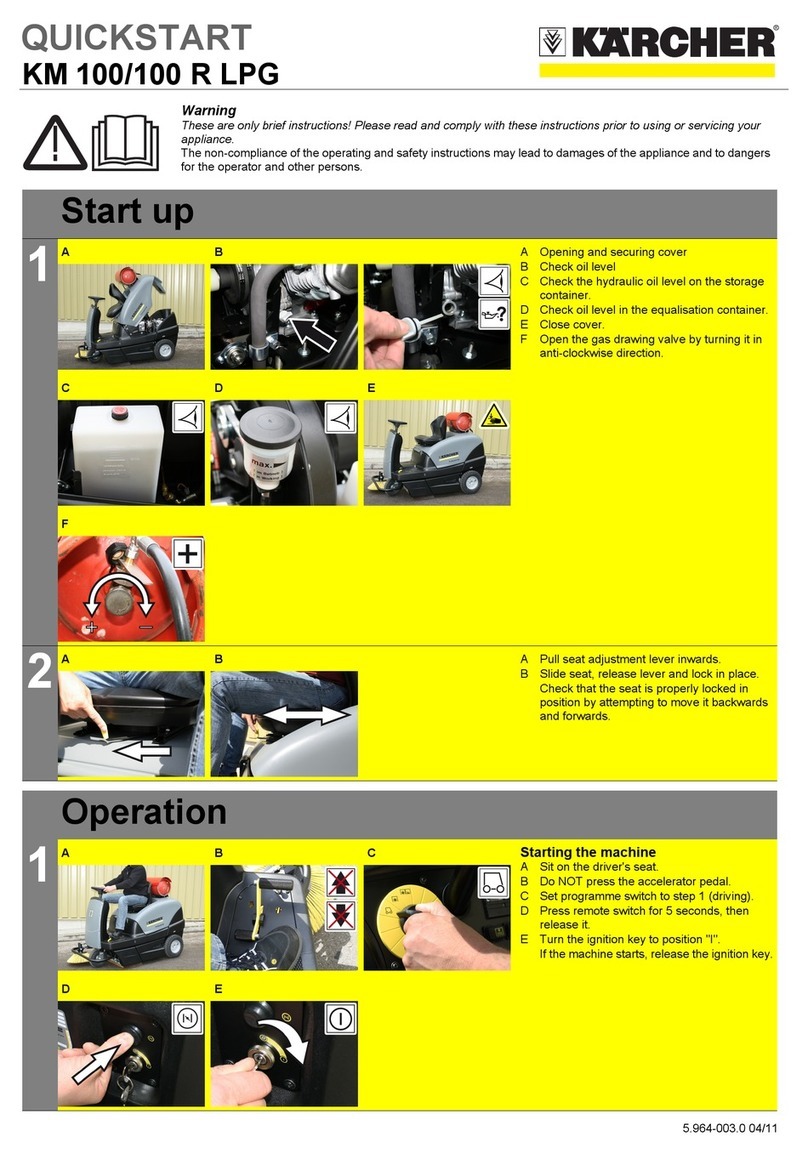

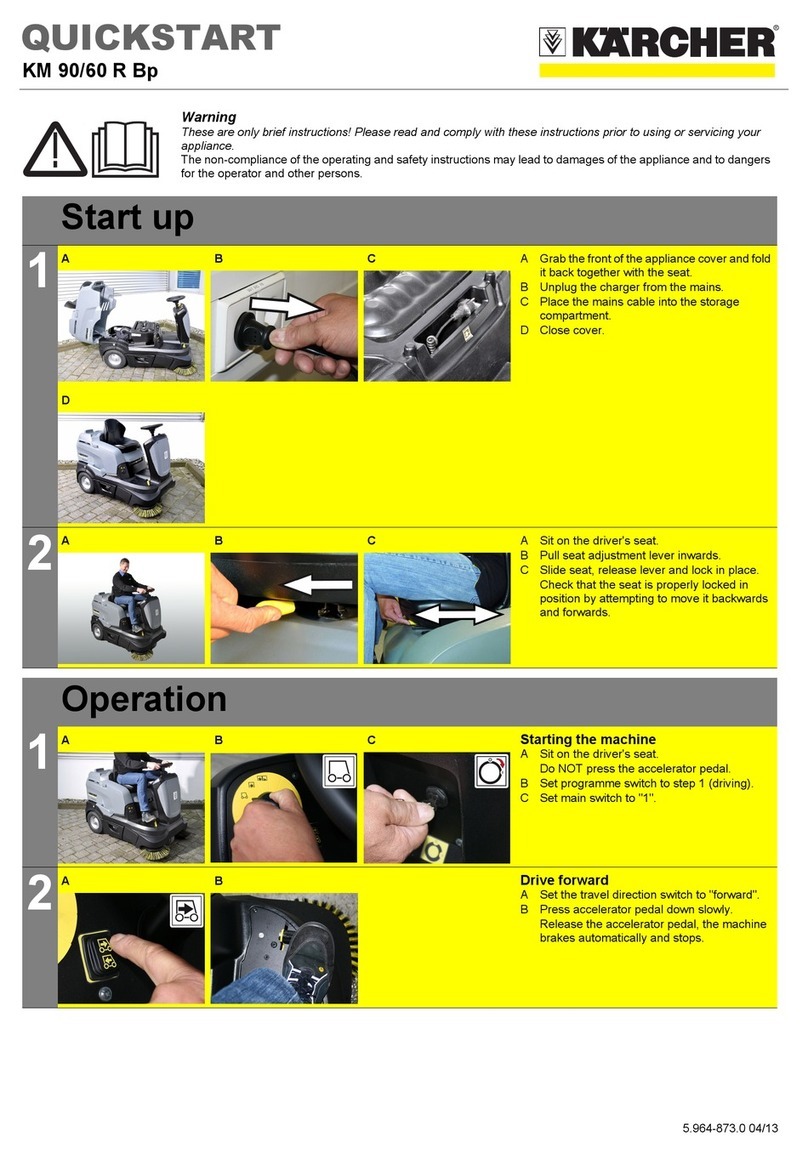

Open/close the unit‘s cover

On opening cover, make sure cover

latch engages.

The lock of the unit’s cover prevents it

from slamming shut again.

Lift cover latch before closing cover.

Power drive

The engine takes appro . 3...4 s to

run down after being shut off.

Never enter operating area during

this period!

FOR PROTECTION OF OUR

ENVIRONMENT

Caution, exhausted batteries can

cause pollution!

♦

Do not dispose of e hausted

batteries as ordinary household

garbage.

♦

All plastic materials are designated

for sorted recycling.

♦

Ensure environmentally compatible

disposal.