- 1

Please read and comply with

these original instructions prior

totheinitialoperationofyourapplianceand

storethem forlater useor subsequentown-

ers.

Before first start-up it is definitely neces-

sary to read the safety indications no.

5.956-250!

These operating instructions describe 2 ap-

pliances or designs.

MIC 34C

This machine is an appliance carrier on

which various attachments (not included in

the scope of supply) can be attached at the

front and at the back, according to require-

ments.

MC 50

This appliance is a sweeper on which fur-

therattachments (notincludedin thescope

of delivery) can be installed.

Usethis appliance onlyasdirected inthese

operating instructions.

–The sweeper has been designed to

sweep dirt and debris from outdoor sur-

faces.

–The appliance carrier is used to store,

operate and transport extra work at-

tachments such as mower decks,

sweeper and sprayer units, etc.

–If not attachment is connected to the

rear of the appliance, you must install

the balance weights on the rear.

–The appliance should not be used in

closed rooms.

–Themachine isnot suitableforvacuum-

ing dust which endangers health.

–The machine may not be modified.

–The machine is only suitable for use on

the types of surfaces specified in the

operating instructions.

–The machine may only be operated on

the surfaces approved by the company

or its authorised representatives.

–The following applies in general: Keep

highly-flammable substances away

from the appliance (danger of explo-

sion/fire).

–Never vacuum up explosive liquids,

combustible gases or undiluted acids

andsolvents.This includespetrol,paint

thinner or heating oil which can gener-

ate explosive fumes or mixtures upon

contact with the suction air. Acetone,

undiluted acids and solvents must also

be avoided as they can harm the mate-

rials on the machine.

–Neversweep/vacuumupreactivemetal

dusts (e.g. aluminium, magnesium,

zinc), as they form explosive gases

when they come in contact with highly

alkaline or acidic detergents.

–Do not sweep/vacuum up any burning

or glowing objects.

–Themachinemay notbeusedor stored

in hazardous areas. It is not allowed to

use the appliance in hazardous loca-

tions.

–Asphalt

–Industrial floor

–Screed

–Concrete

–Paving stones

Contents

Proper use . . . . . . . . . . . . . EN . . 1

Foreseeable misuse . . . EN . . 1

Suitable sweeping surfaces EN . . 1

General notes. . . . . . . . . . . EN . . 2

Accessories and Spare

Parts . . . . . . . . . . . . . . . EN . . 2

Environmental protection EN . . 2

Warranty . . . . . . . . . . . . EN . . 2

Spare parts . . . . . . . . . . EN . . 2

Symbols in the operating in-

structions. . . . . . . . . . . . EN . . 2

Symbols on the machine EN . . 2

Safety instructions . . . . . . . EN . . 3

Application. . . . . . . . . . . EN . . 3

Operation . . . . . . . . . . . EN . . 3

Drive mode . . . . . . . . . . EN . . 3

Applianceswithcombustion

engine . . . . . . . . . . . . . . EN . . 3

Appliances with air tires EN . . 3

Transport. . . . . . . . . . . . EN . . 3

Maintenance . . . . . . . . . EN . . 3

Safety Devices . . . . . . . EN . . 3

Sweeper Functions. . . . . . . EN . . 3

Control elements. . . . . . . . . EN . . 4

Overview MC 50 . . . . . . EN . . 4

Overview MIC 34C . . . . EN . . 5

Ventilation/air conditioning

(option) . . . . . . . . . . . . . EN . . 5

Accessory blower . . . . . EN . . 5

Steering column . . . . . . EN . . 5

Pedals. . . . . . . . . . . . . . EN . . 6

Ceiling panel . . . . . . . . . EN . . 6

Door handle. . . . . . . . . . EN . . 6

Waste container (sweeper) EN . . 6

Connections . . . . . . . . . EN . . 6

Console MC 50 . . . . . . . EN . . 7

Console MIC 34C . . . . . EN . . 8

Before Startup. . . . . . . . . . . EN . . 9

Prior to initial start-up . . EN . . 9

Refuelling . . . . . . . . . . . EN . . 9

Fill the windshield wiper

system . . . . . . . . . . . . . . EN . . . 9

Fill water reservoir (for

sweeper) . . . . . . . . . . . . EN . . . 9

Adjusting driver's seat . . EN . . .9

Set the steering wheel posi-

tion. . . . . . . . . . . . . . . . . EN . . . 9

Prior to start/safety test . EN . . 10

Daily maintenance tasks EN . . 10

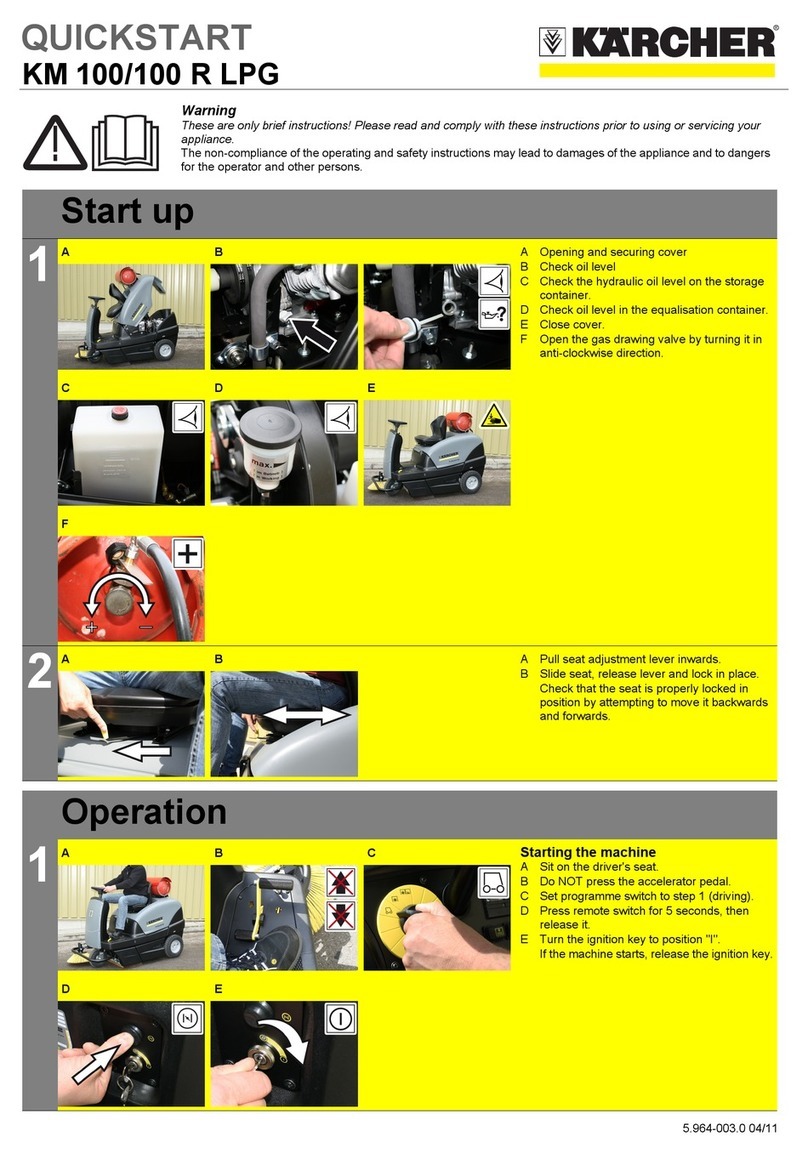

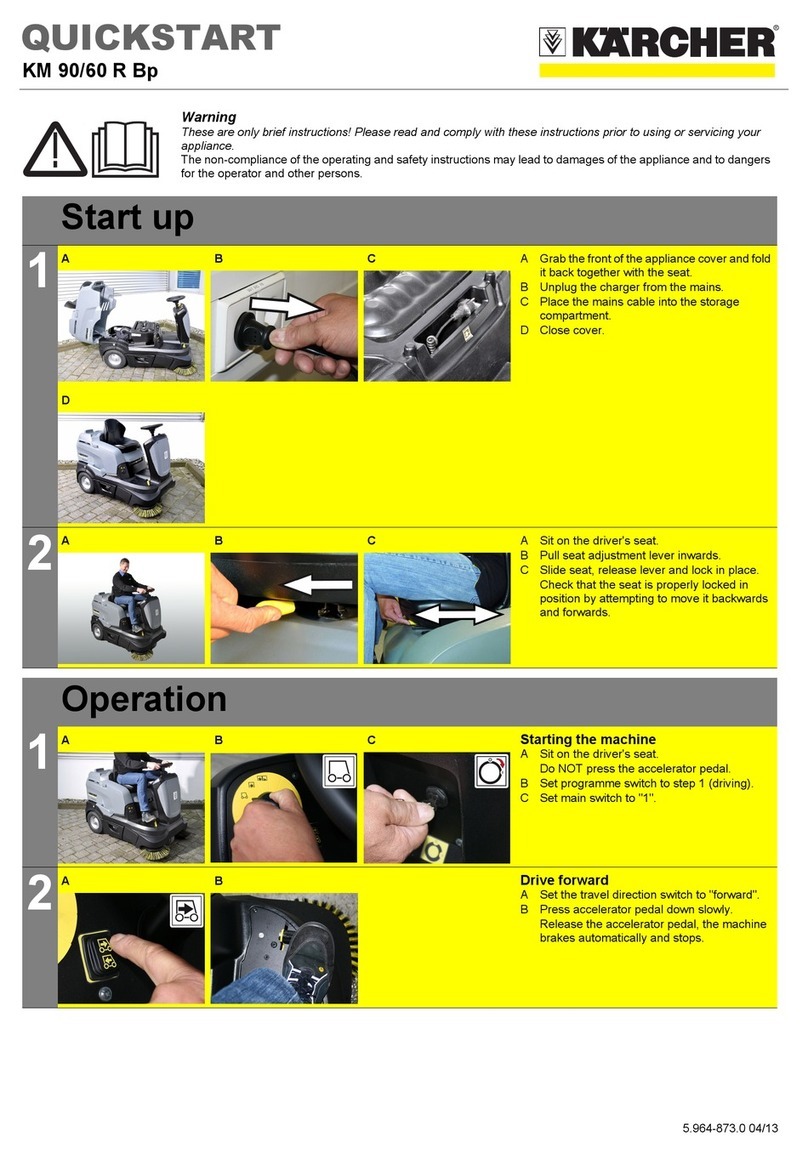

Operation. . . . . . . . . . . . . . . EN . .10

Driving . . . . . . . . . . . . . . EN . . 10

During sweeping operation EN . . 10

Restrict brush immersion

depth . . . . . . . . . . . . . . . EN . . 11

Emptying waste container EN . . 11

Turn off device . . . . . . . . EN . . 11

Frost protection . . . . . . . EN . . 12

Transport . . . . . . . . . . . . EN . . 12

Attachment sets. . . . . . . . . . EN . .12

Preparation for all upgrade

kits . . . . . . . . . . . . . . . . . EN . . 12

Mower 125 cm . . . . . . . . EN . . 12

Mower 135 cm . . . . . . . . EN . . 12

Front brush roller . . . . . . EN . . 13

Snow removal shields . . EN . . 13

Snow blower . . . . . . . . . EN . . 13

Caster . . . . . . . . . . . . . . EN . . 14

Balance weight without at-

tachment hitch . . . . . . . . EN . . 15

Balance weight with attach-

ment hitch . . . . . . . . . . . EN . . 15

Towing hitch. . . . . . . . . . EN . . 15

Storage . . . . . . . . . . . . . . . . EN . . 15

Maintenance and care. . . . . EN . .15

General notes . . . . . . . . EN . . 15

Panels . . . . . . . . . . . . . . EN . . 16

Cleaning. . . . . . . . . . . . . EN . . 16

Maintenance intervals . . EN . . 17

Maintenance Works. . . . EN . . 18

Fuses. . . . . . . . . . . . . . . EN . . 26

Troubleshooting. . . . . . . . . . EN . .28

Faults with display . . . . . EN . . 28

Faults without display. . . EN . . 28

Towing . . . . . . . . . . . . . . EN . . 29

Technical specifications. . . . EN . .30

Centre of gravity of the MC

50 / MIC 34C with sweeping

system . . . . . . . . . . . . . . EN . . 31

Point of gravity MIC 34C EN . . 31

EC Declaration of Conformity EN . . 31

Proper use

Foreseeable misuse

Suitable sweeping surfaces

3EN