Contents

Page

Predelivery Inspection

Predelivery Checklist ...................................CLIST1

Delivery Checklist.........................................CLIST1

AfterSale Checklist......................................CLIST2

Identification View

Identification View...............................................001

Safety

Recognize Safety Information ............................051

Follow Safety Instructions...................................051

Understand Signal Words...................................051

Observe Road Traffic Regulations......................052

Use Safety Lights and Devices...........................052

Prepare for Emergencies....................................052

Wear Protective Clothing....................................053

Check Machine Safety........................................053

Guards and Shields............................................053

Stay Clear of Harvesting Unit .............................053

Keep Hands Away From Knives.........................054

Store Attachments Safely...................................054

Practice Safe Maintenance.................................055

Stay Clear of Rotating Drivelines........................055

Service Machines Safely ....................................056

Support Machine Properly..................................056

Avoid HighPressure Fluids ................................056

Transport with Harvesting Unit Installed.............057

Ballasting for Safe Ground Contact....................057

Remove Paint Before Welding or Heating..........057

Dispose of Waste Properly .................................058

Safety Decals

Pictorial Safety Signs..........................................101

Operator’s Manual..............................................101

Repair and Maintenance ....................................101

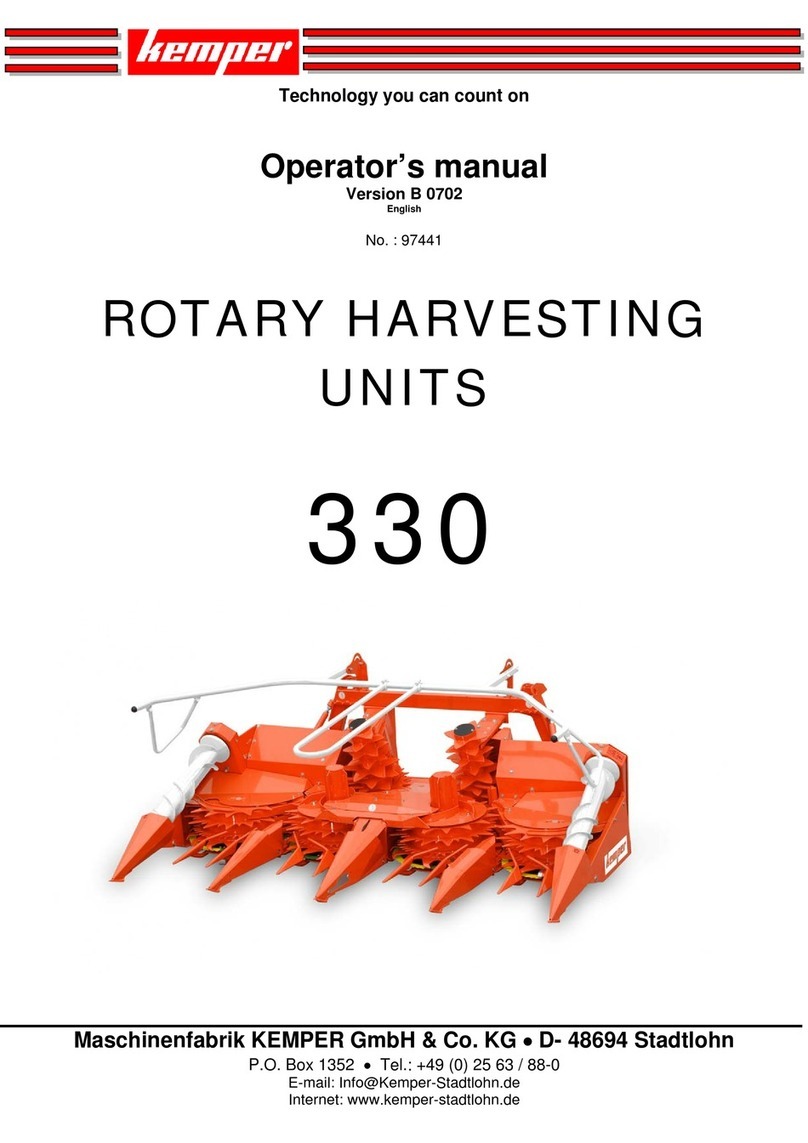

Rotary Harvesting Unit .......................................102

Rotating Blade....................................................102

Folding Area .......................................................103

Rotating Drums...................................................103

Hydraulic System................................................104

Hanging Points ...................................................104

Haulage

Prepare the Rotary Harvesting Unit for

Haulage..........................................................151

Transport Pallet ..................................................152

Page

Loading with a Crane..........................................152

Prepare the Rotary Harvesting Unit

Unpacking...........................................................201

Remove Tensioner Strap ....................................201

Removing the Transport Pallet ...........................201

Align Drive Case (Rotary Harvesting

Units for NEW HOLLAND Forage

Harvesters Only) ............................................202

Adapt the Scrapers to the Feed Passage...........202

Installation on a CLAAS Forage Harvester

Compatibility Chart (Forage

Harvesters, Types 491, 492,

493 and 494) ..................................................251

Installation on the CLAAS Forage Harvester......252

Connect Hydraulic Hoses...................................252

Connect the Drive (Type 492).............................253

Connect the Drive (Types 493 and 494).............254

Installation on NEW HOLLAND and CASE Forage

Harvesters

Compatibility Chart (NEW HOLLAND

and CASE Forage Harvesters) ......................301

Install Mounting Rail ...........................................301

Installation on NEW HOLLAND and

CASE Forage Harvesters...............................302

Connect Drive Shaft ...........................................302

Install Guards for U.J. Shaft on Forage

Harvester........................................................303

Install Guard for U.J. Shaft on Rotary

Harvesting Unit...............................................303

Connect Hydraulic Hoses...................................304

Removal of the Rotary Harvesting Unit

Detach the Rotary Harvesting Unit .....................351

Transport

Transport Information .........................................401

Fold the Rotary Harvesting Unit .........................401

Close Safety Relief Valve (Rotary

Harvesting Units for CLAAS Forage

Harvesters Only) ............................................401

Accident Prevention............................................402

Lock/Unlock Tilt Frame.......................................403

Driving on Public Road.......................................404

Continued on next page

Original Instructions. All information, illustrations and specifications in this

manual are based on the latest information available at the time of publication.

The right is reserved to make changes at any time without notice.

COPYRIGHT © 2009

All rights reserved.

i070909

PN=1