Contents

Page

Fold the Rotary Harvesting Unit .........................35-1

Apply Decal (Rotary Harvesting Units

with Support Wheel).......................................35-1

Driving on Public Roads (Rotary

Harvesting Units with Comfort

Support Wheel) ..............................................35-2

Driving on Public Roads (Rotary

Harvesting Units without Comfort

Support Wheel) ..............................................35-3

Operating the Rotary Harvesting Unit

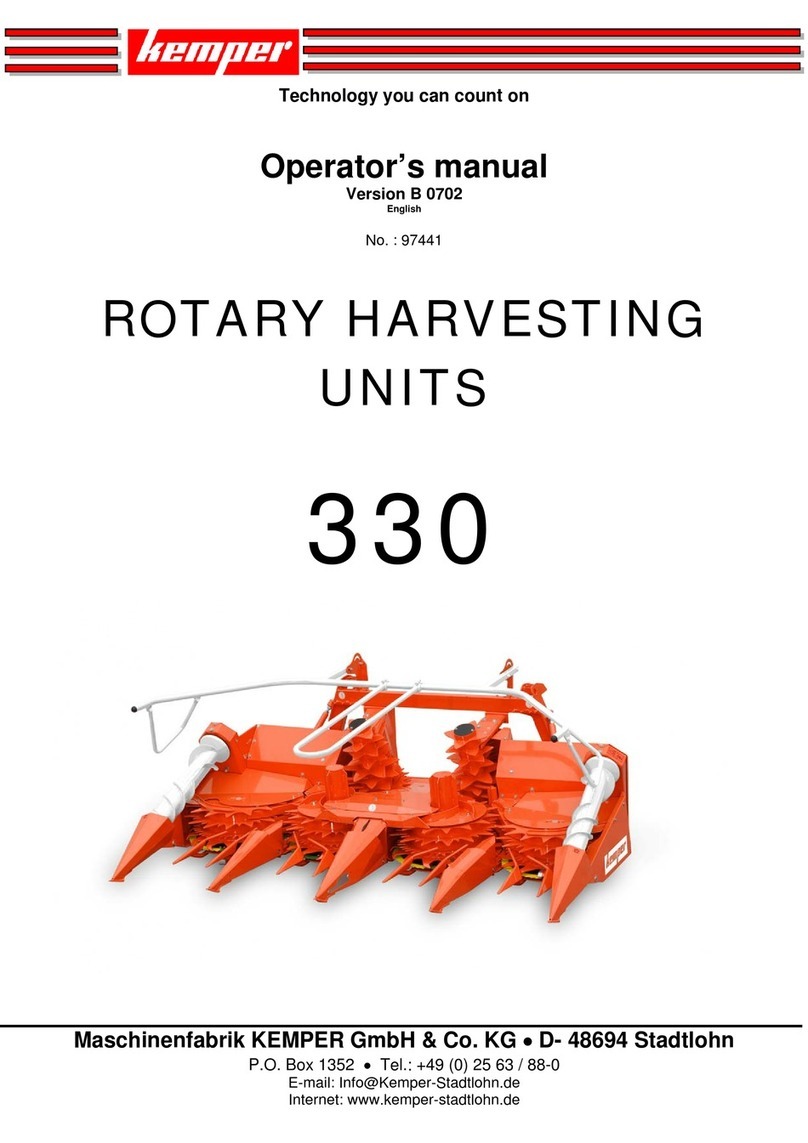

Rotary Harvesting Unit Method of Operation......40-1

Operating the Rotary Harvesting Unit -

General Use ...................................................40-2

Clear Blockages .................................................40-2

Clear Blockages on CLAAS Forage

Harvesters......................................................40-2

Feeder House Drum Operating Speeds .............40-3

Adjusting Gear Selection with

Multi-Speed Gearbox for CLAAS

Forage Harvesters .........................................40-4

Lengths of Cut and Gear Selection

with Multi-Speed Drive for CLAAS

Forage Harvesters .........................................40-5

Harvesting ..........................................................40-6

Hydraulic System................................................40-6

Troubleshooting

490plus Rotary Harvesting Unit............................45-1

Lubrication and Periodic Service

Service Intervals.................................................50-1

Fluid Grease for Drives.......................................50-1

Transmission Oil.................................................50-1

Coolant for Main Drive Friction Clutch................50-2

Alternative and Synthetic Lubricants ..................50-2

Mixing Lubricants................................................50-2

Lubricant Storage ...............................................50-2

At the Start of Every Harvesting Season............50-3

Use Genuine KEMPER Parts ............................50-3

At the Start of Every Harvesting

Season—Spherical Collar Bolts .....................50-3

At the Start of Every Harvesting

Season—Transmission Mounting

Flange Attaching Screws ...............................50-4

At the beginning of each harvesting

season — adjust latch of the chassis.............50-5

General View of Drives and Oil Levels

on the Rotary Harvesting Unit ........................50-6

Overview of Oil Levels in Input Transmission.....50-7

Every 10 Hours of Operation—Clean-

ers and Blade Rotor Segments ......................50-7

Every 10 Operating Hours—Balance Weights ...50-8

Every 50 Hours—Claw Clutch ............................50-8

Every 50 Hours—Lower Pin of

Hydraulic Cylinder and Pivots of the

Outer Units .....................................................50-9

Page

Every 50 hours of operation—Upper

rollers of the tilt frame (rotary

harvesting units for CLAAS forage

harvesters) .....................................................50-9

Every 50 hours of operation—Lower

rollers of the tilt frame (rotary

harvesting units for CLAAS forage

harvesters) .....................................................50-9

Every 50 hours of operation—Spring-

loaded pins...................................................50-10

Every 50 hours of operation—Axle pins

of the outer units ..........................................50-10

Every 50 operating hours—Fold cylinders........ 50-11

Every 50 operating hours—Latch jaws.............50-12

Every 3 Years—Change Coolant of

Main Drive Friction Clutch ............................50-13

After each harvesting season...........................50-14

Service

Metric Bolt and Screw Torque Values.................55-1

Check Main Drive Slip clutches ..........................55-2

Disassemble Slip Clutch.....................................55-3

Installing New Rotating Blades...........................55-4

Adjusting the Dividers.........................................55-5

Checking Adjustment of Scrapers

(Inner Drums) .................................................55-6

Checking Adjustment of Scrapers

(Outer Drums) ................................................55-6

Check Condition of Cleaners..............................55-7

Cleaning Rotary Harvesting Unit ........................55-8

Storage

Storage at End of Harvesting Season ................60-1

Start of New Season...........................................60-1

Technical specifications

Machine Design Life...........................................65-1

Rotary Harvesting Unit 490plus............................65-1

Sound level.........................................................65-1

EU Declaration of Conformity .............................65-2

Serial Number

Rotary Harvesting Unit Serial Number Plate ......70-1

Serial Number.....................................................70-1

ii 120519

PN=2