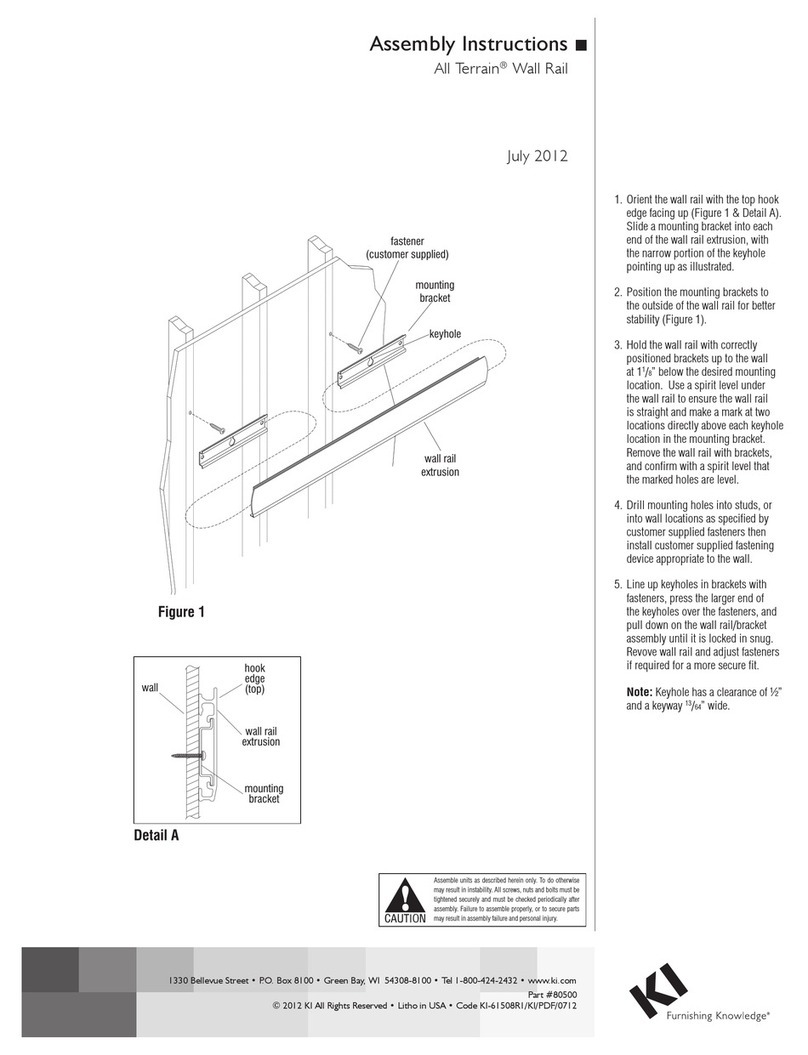

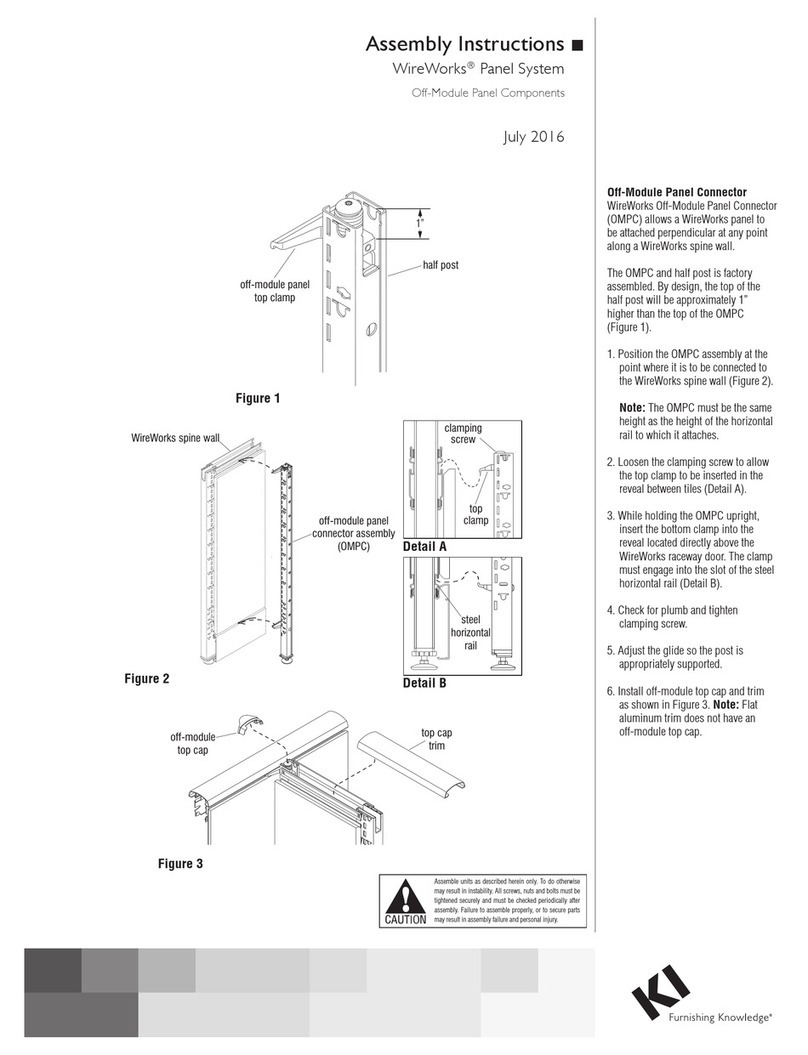

WireWorks®ADA Height Countertop

Assembly Instructions

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

3

Corner ADA Height

Note: The following instructions

refer to the installation of a

two-piece 90° right angle

countertop. The countertop surface

is to be used on two 30” high panels

which place the countertop no

higher than 33”. Per the 2010 ADA

and ICC A117.1, KI countertops

do not extend more than 4 inches

into a circulation path, and meet the

requirements for a clear floor space,

positioned for a parallel approach

adjacent to the accessible counter.

Using supplied ADA brackets, the

countertop extends no more than 4”

into the aisle. Brackets, which are

mounted on the inside and outside of

station, include steel locking clips on

the inside to prevent dislodgement.

All brack-ets are handed, “L” or “R”

is stamped into the flange of each for

identification. Countertop accepts

task light on receptionist side.

Clearance between countertop and

29” high work surface is only 4”.

Note: For the installation of

90°countertops onto 30” high

panels, it is required that no

worksurface or cantilever brackets be

in place until later in the installation

process.

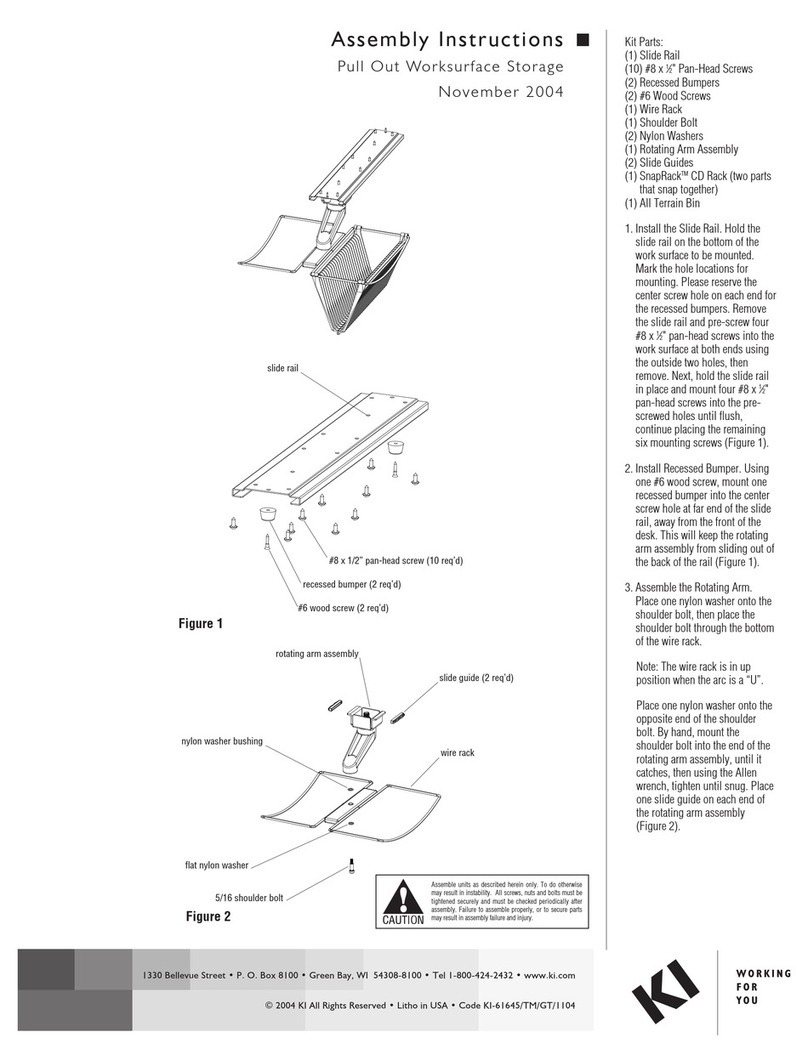

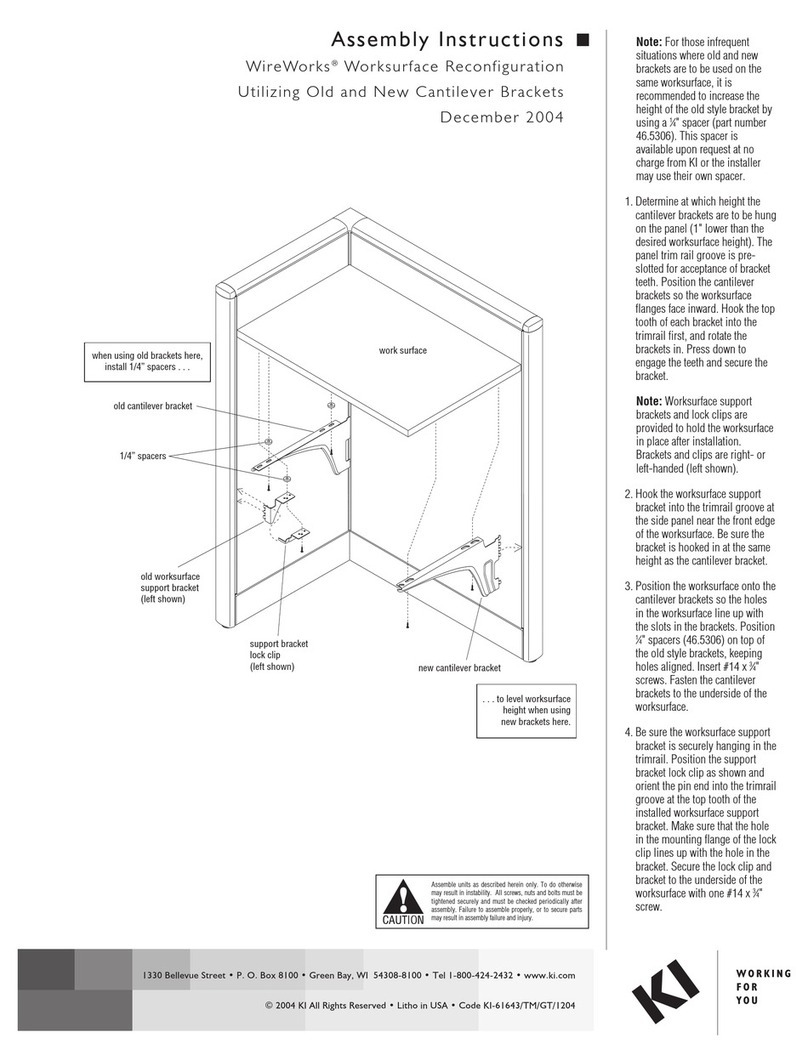

1. Begin countertop assembly

at the aisle side, or outside

of the workstation. For 90°

countertops installed on two 30”

panels meeting at a corner, three

ADA outer countertop brackets

are required, two left-, and one

right-hand. Mount the appropriate

ADA outer countertop brackets

into the slots in the posts so the

mounting flanges are 1/8” higher

than the panel top caps. The right-

and left-hand brackets will be

different. Notice that the mounting

flanges of the two outside

brackets face inward as installed

to the panel (Figure 1).

2. Mount the three ADA inner

countertop brackets into the slots

in the post at the same height

as the outer brackets, but on the

side that the corner worksurface

will later be installed to (inside

the workstation). Orient the

outside brackets also with the

mounting flanges facing inward as

illustrated (Figure 1).

Note: The inner lock clips are

an important part of the bracket

assembly which must be installed

later when the 90° countertop

surface is installed.

3. Carefully place the 90°countertop

face up onto the 30” panels. Align

the mounting holes of the three

ADA outer countertop brackets

with corresponding pre-drilled

holes at the underside of the 90°

countertop surface. Loosly attach

the three outside brackets to the

underside of the countertop with

two #14 x 3/4” screws at each

location. Do not tighten at this

time (Figure 1).

4. Take a right-hand and two left-

hand inner lock clips (inside the

workstation) and orient the pin

ends into the slots in the post at

the top tooth of each installed

ADA inner countertop bracket.

Make sure the mounting flanges

of the two outside clips orient

inward and the mounting holes

of the lock clip line up with the

mounting holes of the bracket.

Secure inner brackets and lock

clips to the underside of the

countertop with one #14 x 3/4”

screw at each bracket location.

Tighten all inner and outer bracket

screws at this time

(Figure 1).

5. To begin installation of the

corner worksurface, mount three

cantilever brackets into the slots

in the post (approximately 28-29”

from the floor) (Figure 1).

Note: Depending on the type of

worksurface being installed, either

a #14 x 3/4” screw, or a

1/4-20 x 3/4” PPH machine screw

will be supplied to attach the

worksurface.

6. Carefully position the corner

worksurface onto the cantilever

brackets. Align the bracket

mounting holes to the

pre-drilled holes under the

worksurface and secure using

two worksurface screws at each

cantilever bracket (Figure 2).

#14 x 3/4"

screw

#14 x 3/4"

inner

lock clip

bracket

ADA outer

countertop

bracket

countertop

bracket

inner

lock clip

cantilever

bracket

30" height

wall panel

90°countertop

surface

worksurface

worksurface

cantilever

bracket

Figure 1

Figure 2