1330 Bellevue Street • P.O. Box 8100 • Green Bay, WI 54308-8100 • Tel 1-800-424-2432 • www.ki.com

© 2016 Krueger International, Inc. All Rights Reserved • Code KI-61506R2/KI/PDF/0716

WireWorks®Panel System - Off-Module Panel Components

Parts Diagram

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

1 /”gap

3

4

between worksurface

and panel

WireWorks

spine wall

off-module bracket allows 6” of

vertical adjustment from 24” to 30”

(above finished floor)

cantilever brackets hung from

off-module worksurface brackets

wireworks spine wall

off-module

panel connector

cantilever brackets hung

directly in panel slots

WireWorks wing wall

off-module

panel connector 1 /”gap between work

3

4

surface and panel

corner worksurface

cantilever bracket in

“end-of-run” position

standard

cantilever bracket in

“shared” position

1”

off-module

worksurface bracket

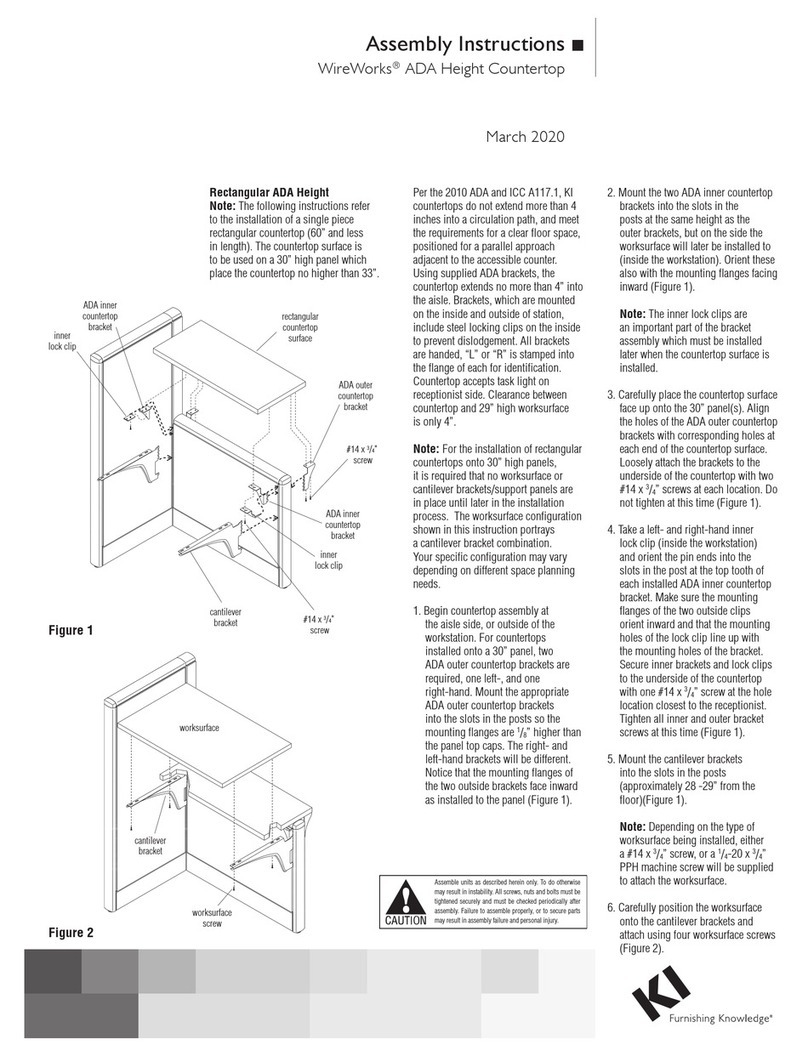

WireWorks Off-Module

Worksurface Bracket

Allows a worksurface to be attached

at any point along a WireWorks

spine wall. The bracket is spaced

away from the panel 3/4” to allow the

removal of tiles from the spine wall.

The use of these brackets will create

a 13/4” space between the rear edge

of the worksurface and the tile of the

spine wall (Figure 4).

1. Position the off-module bracket

at the point where it is to be

connected to the WireWorks

spine wall (Figure 4).

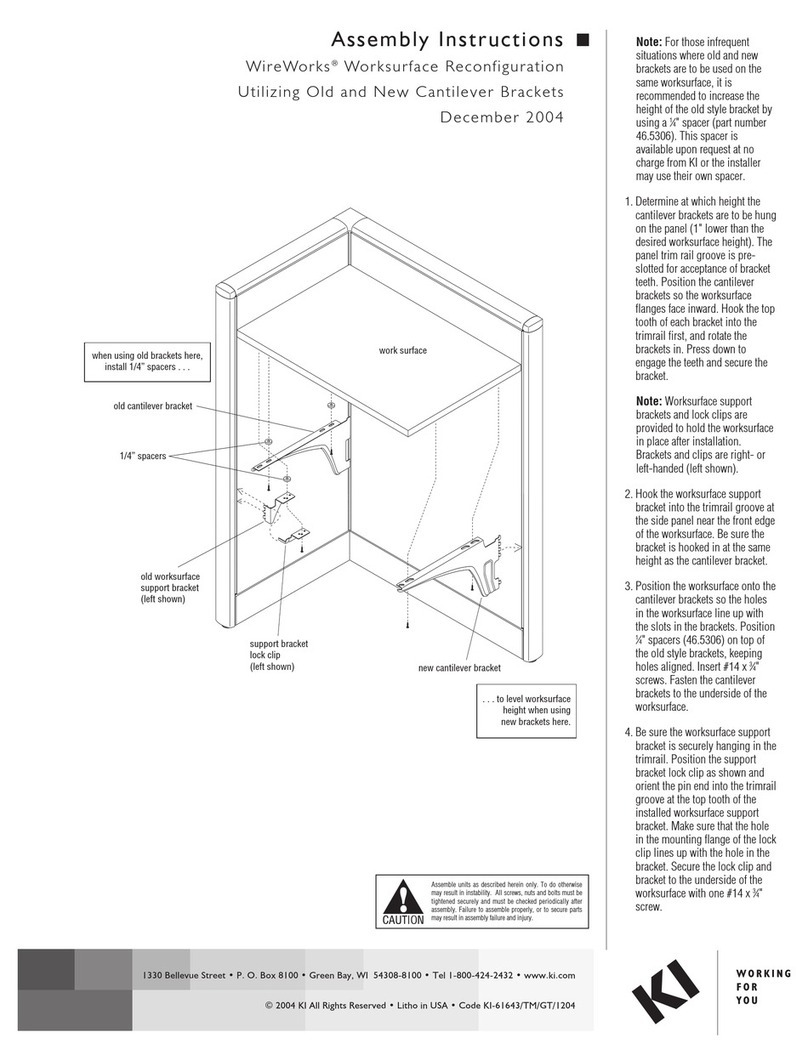

2. Corner worksurfaces can be

attached to the spine wall using

off-module connectors and

then connected directly to the

perpendicular wing wall using

cantilever brackets (Figure 5).

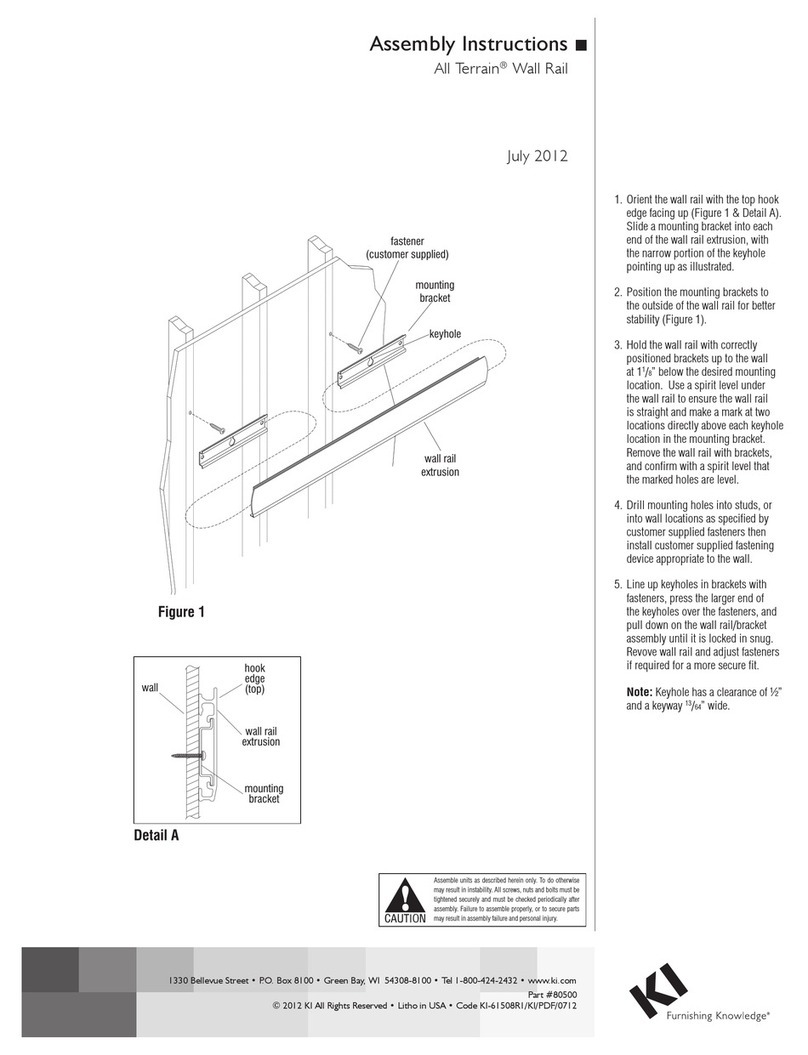

3. Loosen the clamping screw to

allow the top clamp to be inserted

into the reveal between tiles

(Detail C).

4. While holding the off-module

bracket upright, insert the bottom

clamp into the reveal located

directly above the WireWorks

raceway door. The clamp must

engage into the slot of the steel

horizontal rail (Detail D).

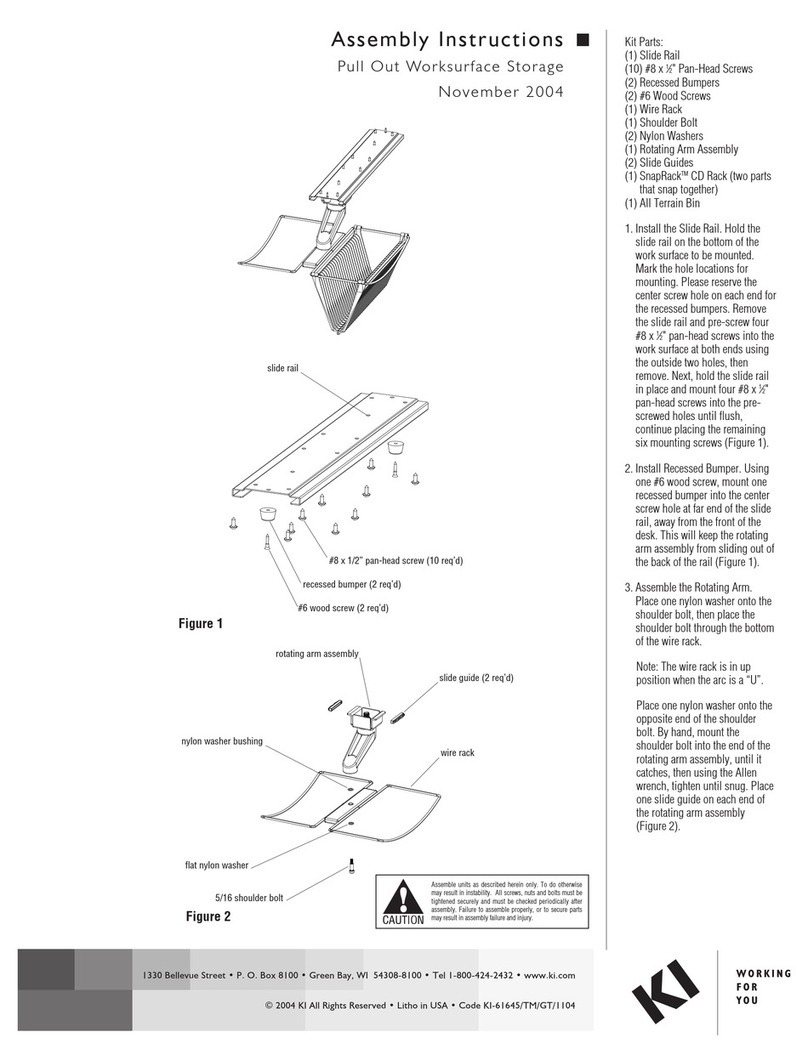

5. The position of the cantilever

bracket (under the worksurface)

when used to support two

“shared” worksurfaces is 1”

different than when used as an

“end-of-run” bracket (Figure 6).

6. Check for plumb and tighten

clamping screw.

7. Engage the teeth of the

worksurface cantilever brackets

into the vertical slots of the

off-module bracket.

8. Position the worksurface on the

cantilever in either the “shared”

or “end-of-run” position

(Figure 6).

9. Mark and drill pilot holes for

#14 x 1” tapping screw,

then install to underside of

worksurface.

Figure 4

Figure 5

Figure 6

Detail C

Detail D