8

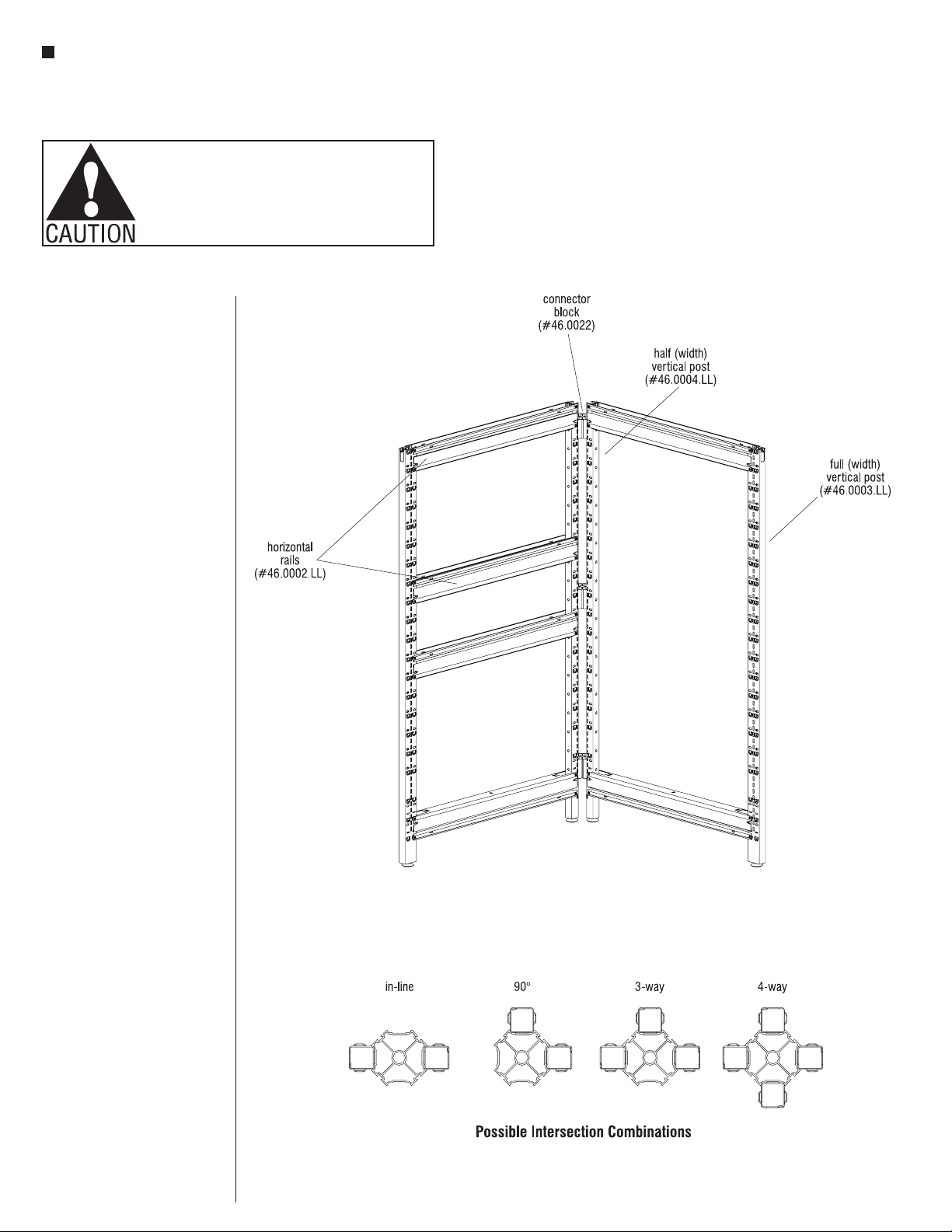

WireWorks®Panel System

Assembly Instructions

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

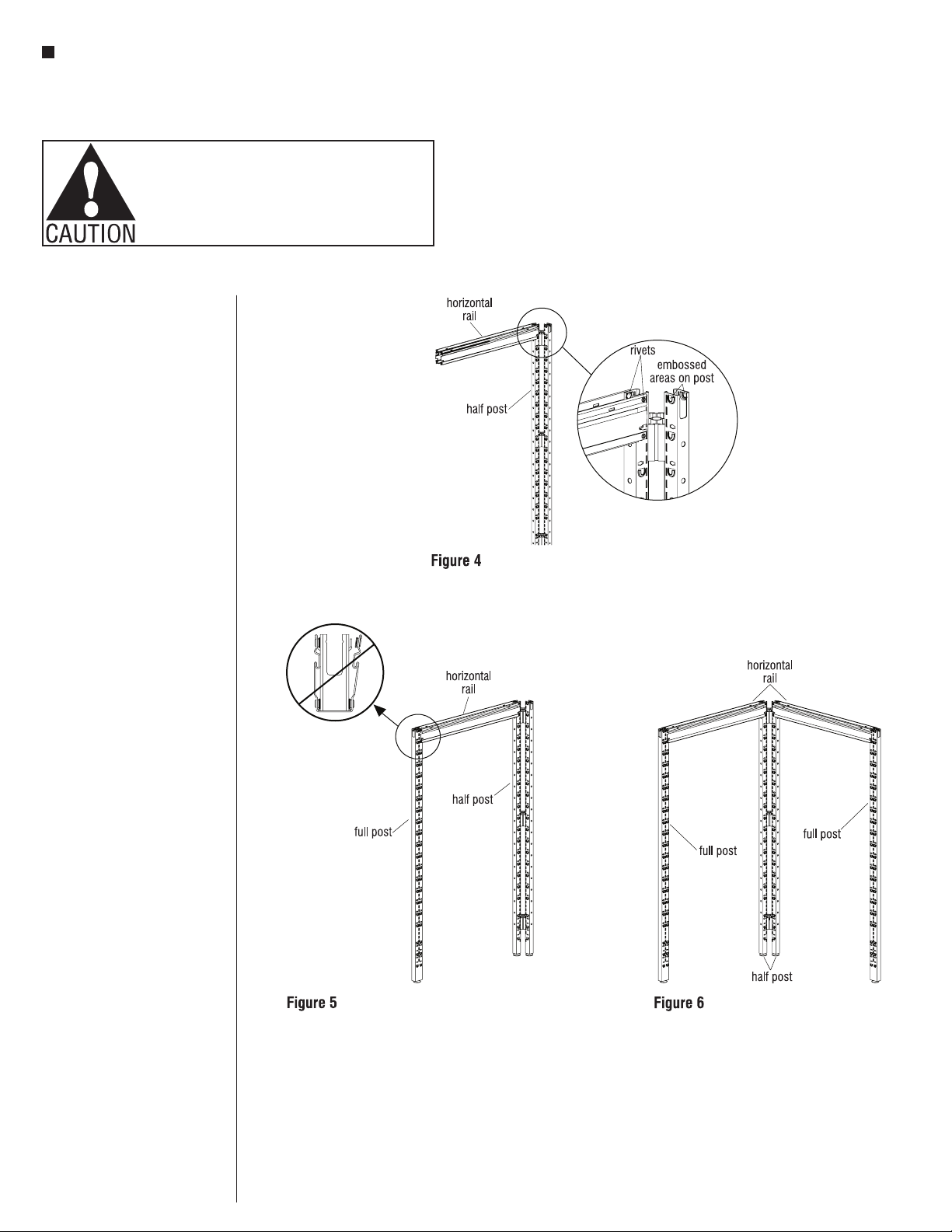

Attaching Horizontals To

Verticals

Horizontals are used at the top

and bottom of a panel to space

the vertical posts apart the

appropriate distance for the panel

width you are building. One rail is

used at the top of the panel with

the opening facing upward and

one rail is used at the bottom

facing downward. Panels that

are made up of more than one

tile also use horizontals at

intermediate heights (with the

opening facing up).

Note: Refer to the

space-planning layout and start

with a panel corner intersection,

building out in two directions so

the panel frame is able to stand

on its own.

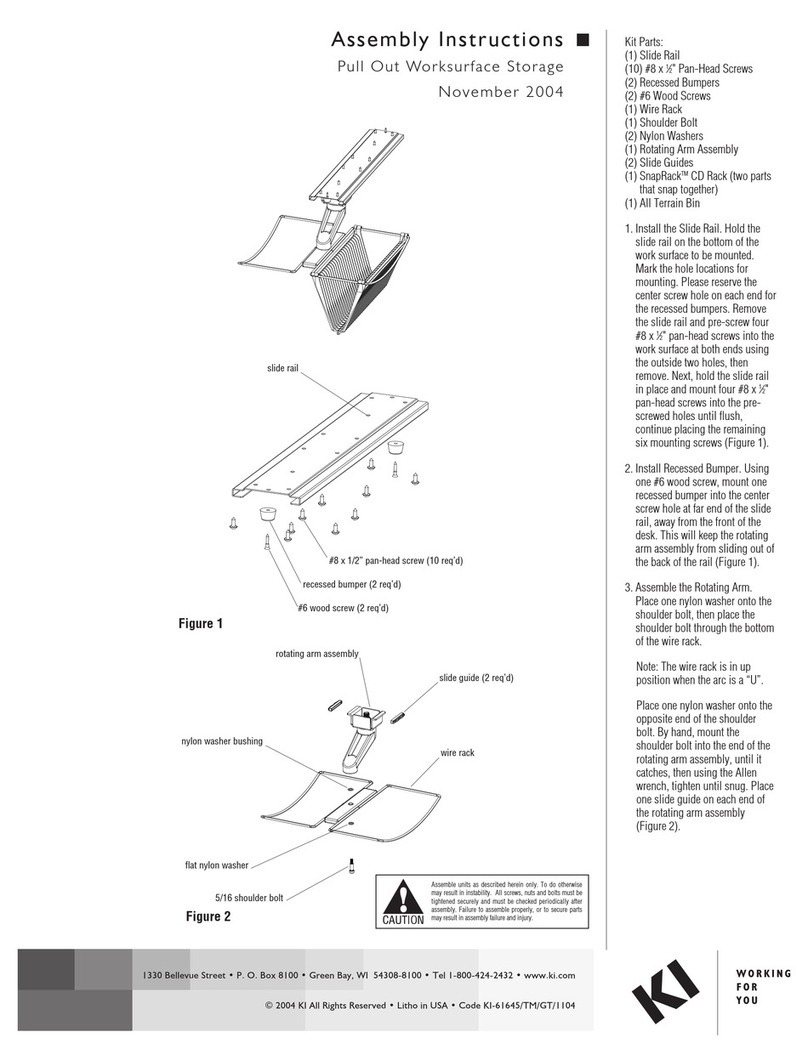

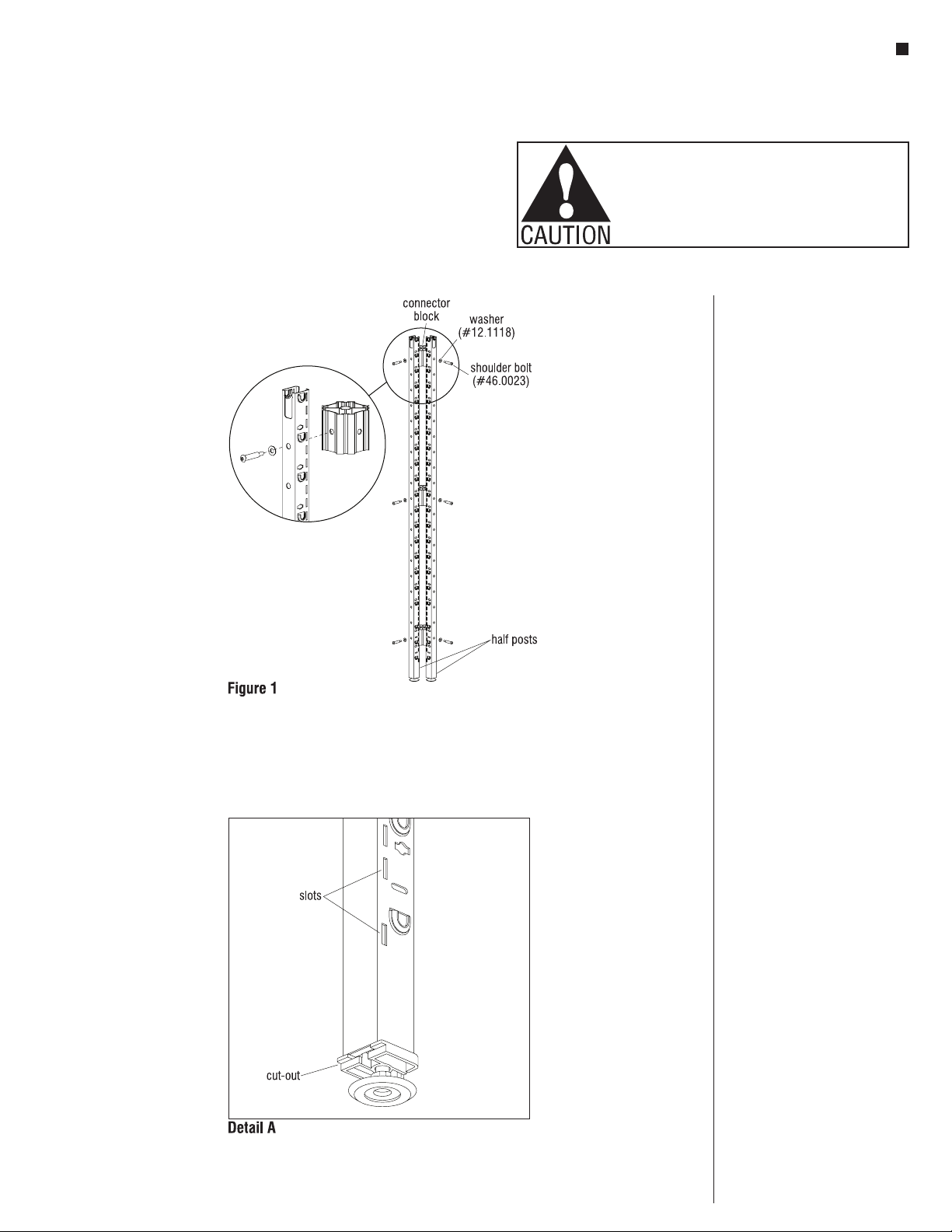

1. Slide a horizontal into the top of

a vertical half post with the rivets

above the pocket on the post.

Making sure all four rivets are

lined up with the corresponding

embosses, tap the horizontal into

place with a dead-blow style

mallet (Figure 4)

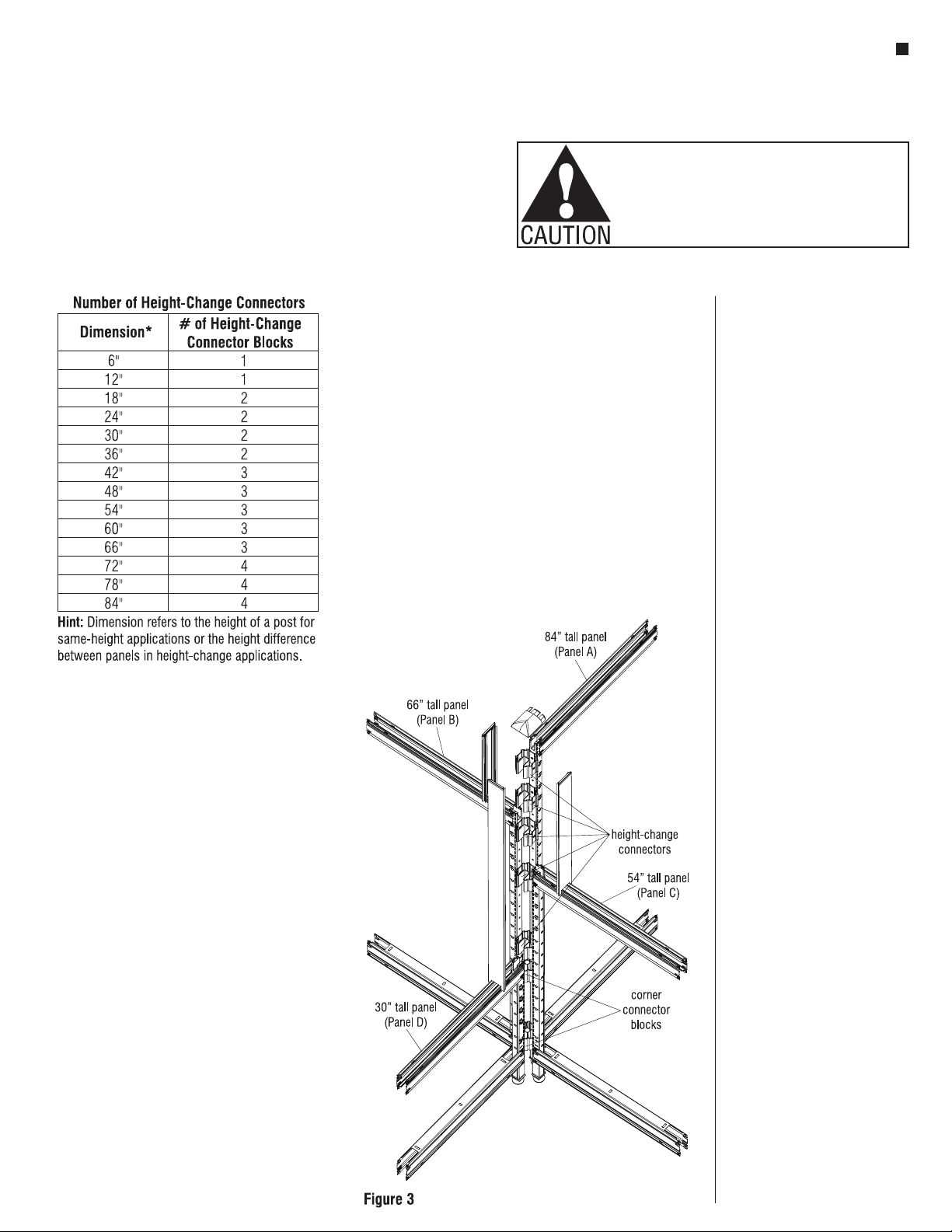

2. Referring again to the

space-planning layout, position

the appropriate vertical post

(full or half post) relative to

the horizontals and tap the

horizontals into place (Figure 5).

3. Repeat the above instructions,

building out in a direction

perpendicular to the first

horizontals from the corner post.

When this step is completed you

should have a partially assembled

90° corner that can support itself

(Figure 6).