Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

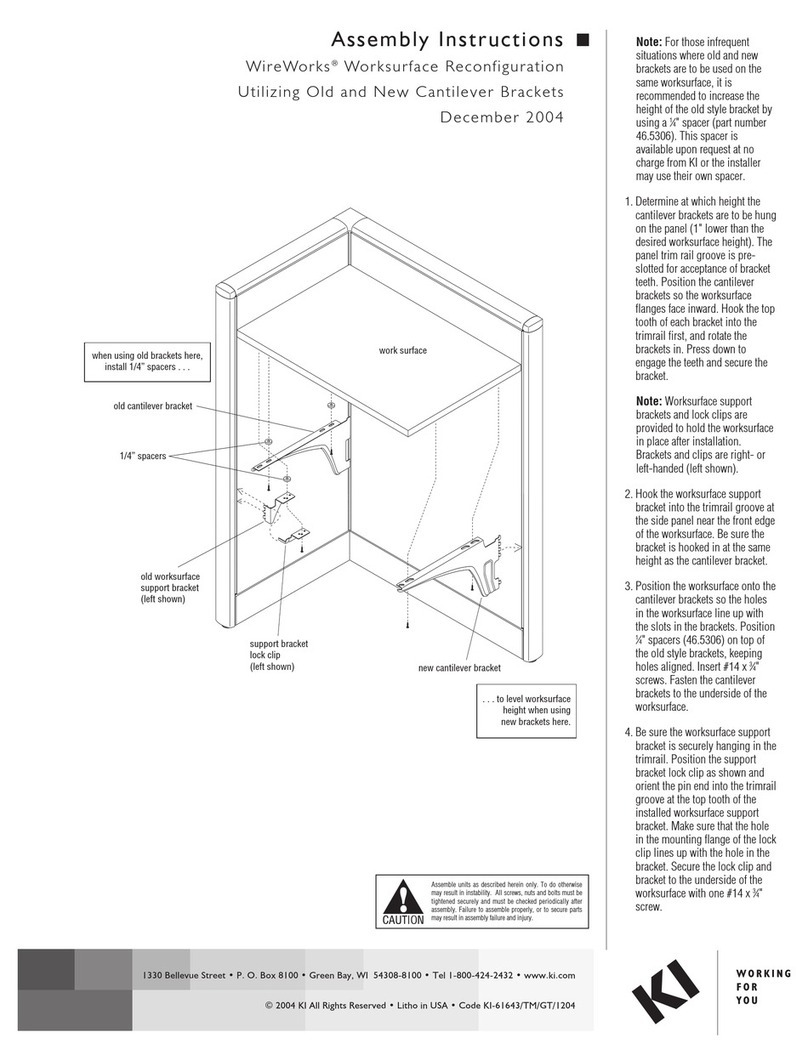

Note: Two types of mounting

hardware are provided for use with

the center mounting hole of the

mounting plates. The 1/4-20 x 3”

double-end hanger bolts are for

wood stud applications, and the

1/4-20 x 21/4” set screws with 1/4-20 x 3”

toggle anchors are for steel stud

applications. The hardware to be

used in the outside mounting holes

on the plate are customer supplied.

Select the correct type of mounting

hardware to use based on your wall

construction.

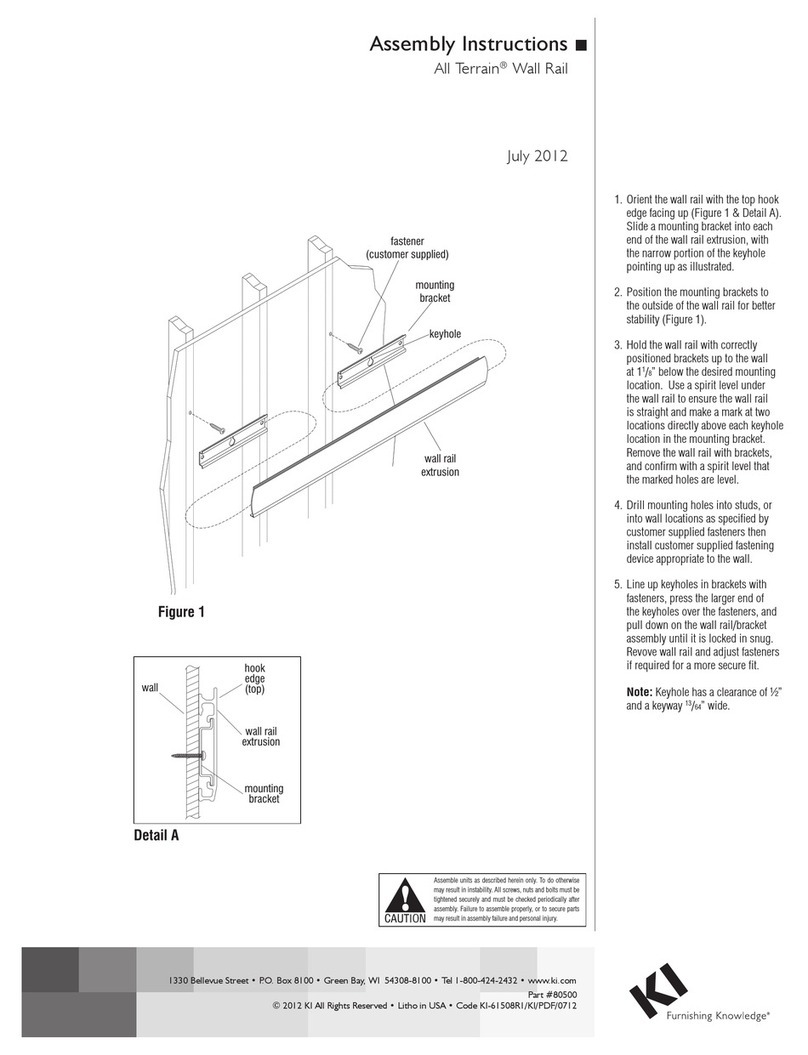

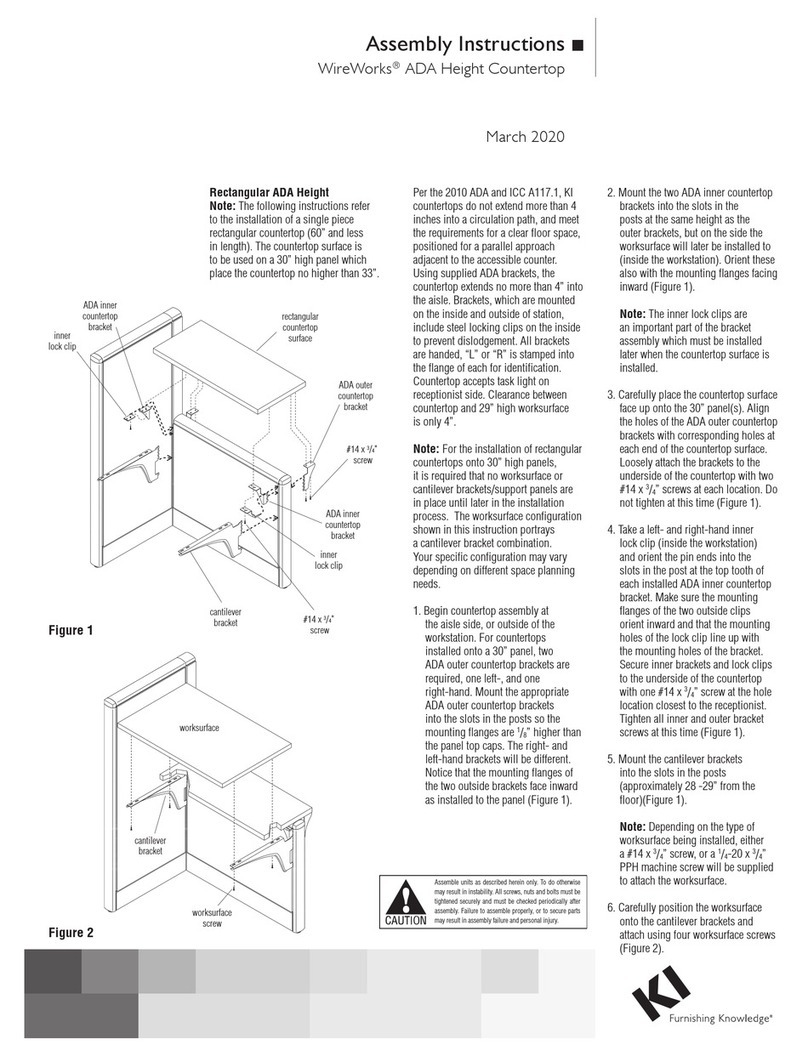

1. Assess wall stud locations with

reference to mounting locations on

the shelf back, then determine the

location and height at which the shelf

will be mounted to the wall. Position

the shelf up to that location, about

1/2” above desired height and turn

the shelf’s top surface to face against

the wall, so the shelf mounting

holes face down. Use a spirit level to

assure the shelf is level and straight,

move the level away, hold the shelf

level and mark a horizontal straight

line at the installation location of the

shelf.

Assembly Instructions

Likha Casegoods

Floating Shelves

August 2021

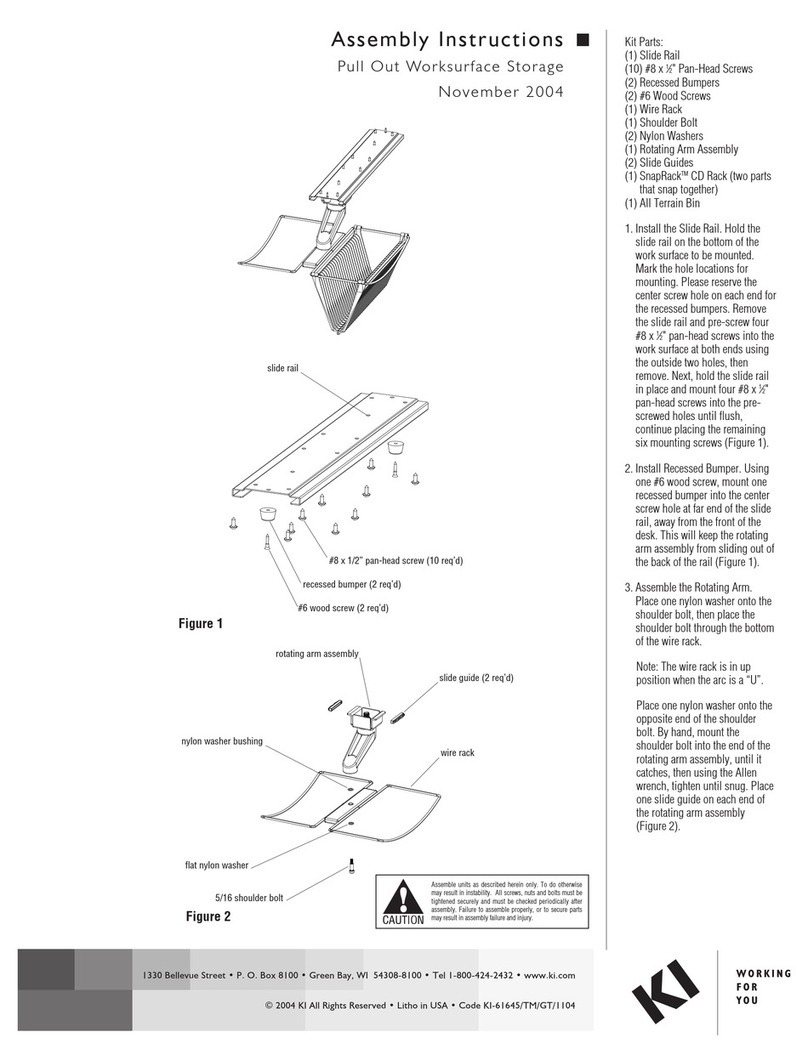

steel rod

mounting

plate

1

/ -20 x 3”

4

double-end hanger bolt

(wood stud applications)

wood stud

at notch

for wrench

1

/ -20 toggle anchor

4

(

ste

steel rod

plate

2

at notch

for wrench

1

/

4

-20 x 3”

set screws

(non-wood stud applications)

2. While still holding the shelf top

surface against the wall on the

marked line (from step 1), make

vertical marks onto the horizontal

line at the exact center of each of the

shelf back‘s mounting holes, making

sure to align as many mounting

holes as possible, with either a wood

or steel stud.

3. Use a mounting plate as a template,

positioned onto the horizontal line

on the wall, then position and center

the middle hole of the bracket exactly

over a vertical mark on the line from

step 1. Assure the bracket is straight

on the line on the wall, then precisely

mark the two outer hole locations

onto the line on the wall. Carefully

bore the appropriately sized pilot

hole at the center of each marked

location, noting if the location is in

a wood stud, steel stud or dry wall

application. Repeat this step to mark

and pre-drill the remaining mounting

hole locations along the line on the

wall.

4. The steel rods which support the

shelf must be set up in one of two

ways: If the steel rod will be installed

into a wood stud, thread a 1/4-20 x 3”

double-end hanger bolt into the steel

rod. If the steel rod will be installed

into a steel stud or dry wall, thread a

1/4-20 x 21/4” set screw into the steel

rod. Repeat this step to assemble the

remaining steel rods (Figures 1 & 2).

5. If any of the assembled steel rods

are for non-wood stud applications,

1/4-20 toggle anchors need to be

installed into the center mounting

hole locations on the wall first,

otherwise proceed to step 6. Hold the

metal bracket down flat against the

plastic straps of the toggle anchor

and insert into the center mounting

hole on the wall. Hold the ends of

straps together, pull away from the

wall until bracket rest behind the wall

at 90°. Slide rachet cap along straps

until flange of cap is flush with wall.

Snap off both straps, level with the

flange cap.