8

TROUBLE SHOOTING

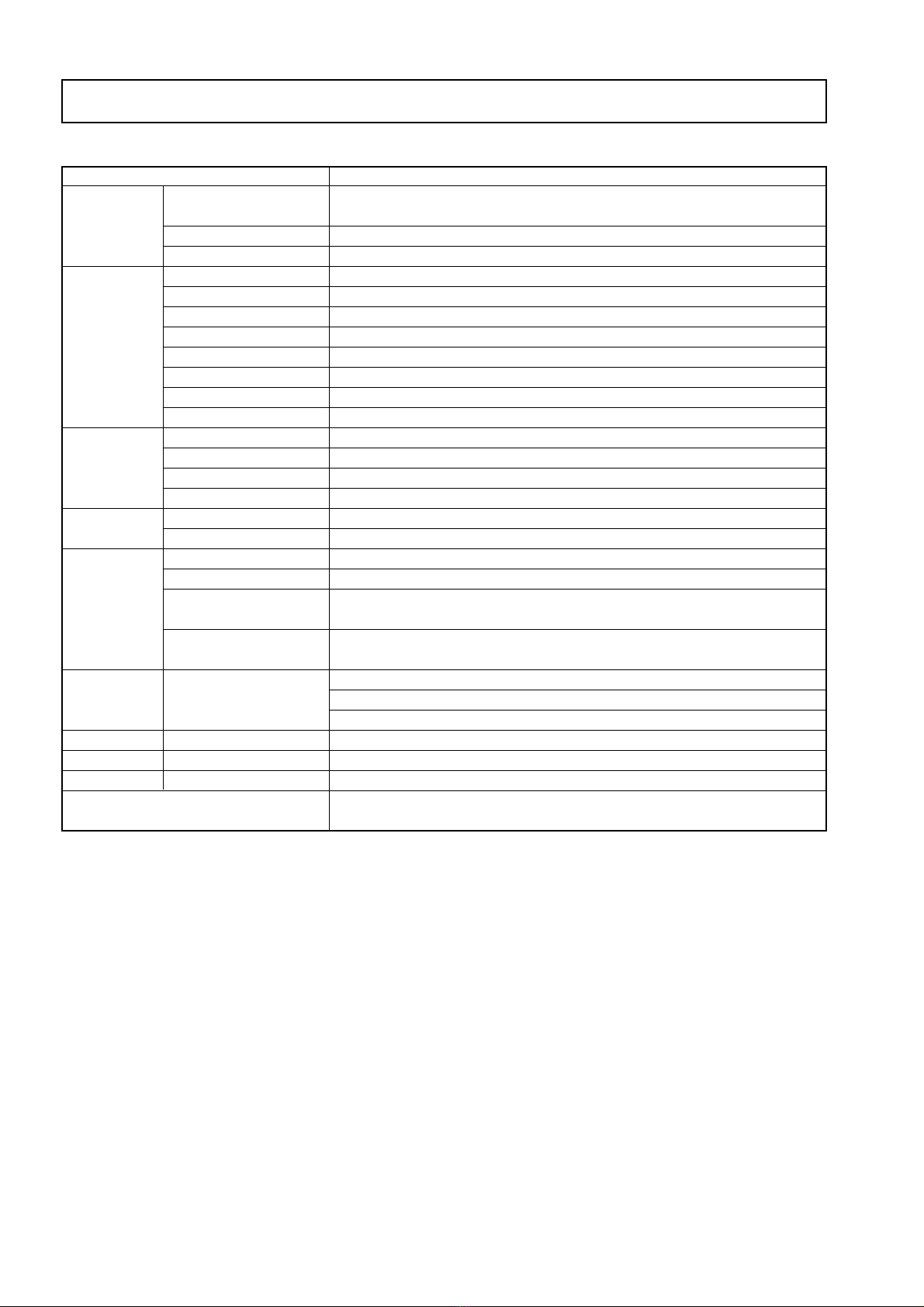

3-2. Error Log List

When an error occurs during normal processing, an “M5.ERR”file is created and the contents of an error are left based on

the additional write system. The “M5.ERR”file is created in CF during CF insertion. It is created in internal flash during CF

non-insertion.

The contents of log and the corresponding contents of an error are shown in the table below.

No Contents of log Contents of error

1 Initial Flash Erase Error The erasure of internal Flash fails during AC ON.

2 Initial SRAM Test Error An error occurs in R/W of SRAM during AC ON.

3 Initial Flash Format Error The format of internal Flash fails during AC ON.

4 CCFL Off Over Error The CCD output is too high just before CCFL lights.

5 Scan CCFL Can’t ON Error CCFL lights, but the CCD output is too low.

6 Scan Peak Detect Error The peak value of CCD output cannot be detected during scan start.

7 Image Buff Write Error The write of special compression data in a buffer fails during scan.

8 Image Buff Overflow Error

The amount of special compression data exceeded the capacity of a buffer during scan.

9 User Cal. Flash Access Error An ini/inf file cannot be accessed by simplified calibration.

10

User Cal. White Level Store Error

The White Level write in an inf file by simplified calibration fails.

11 Scan Start Flash Access Error An ini/inf file cannot be accessed during scan start.

12 CCFL ON Flash Access Error

An ini/inf file cannot be accessed during start of stabilized CCFL light quantity operation.

13 Feed Flash Access Error An ini/inf file cannot be accessed during feed start.

14 Conf. Load Flash Access Error An ini file cannot be loaded.

15 CF Write (Image) Error The write of image data in CF fails. (CF access error)

16 Flash Write (Image) Error The write of image data in flash fails. (Flash access error)

17 Position Set Conf. Load Error The loading of an ini file fails during position setting.

18 Position Set Conf. Scan Error The search of an ini file fails during position setting.

19 Position Set Write Cal. Error The write of an ini file fails during position setting.

20 USB_in CF Config Error The configuration execution of CF fails during USB insertion. (CF access)

21 CF_in CF Config Error The configuration execution of CF fails during CF insertion. (CF access)

22 CF_in JOB ck Error The JOB file check of CF fails during CF insertion.

23 CF Free Byte ck Error The empty capacity check of CF fails. (CF access)

24 Flash Free Byte ck Error The empty capacity check of Flash fails. (Flash access)

25 Ini_file_ck Write Cal. Error The write of a default ini file fails during AC ON.

26 Ini_file_ck Change Conf. Error The modified write of the illegal data in an ini file fails during AC ON.

27 Inf_file_ck Write Cal. Error The write of a default inf file fails during AC ON.

28 Inf_file_ck Change Conf. Error The modified write of the illegal data in an inf file fails during AC ON.

29 Image File Move Error The movement of image data from Flash to CF fails.

30 Image Move Flash Delete Error The image deletion of flash fails during movement of image data from Flash to CF.

31 Image Erase Flash Delete Error The image deletion of flash fails during erasure of the whole Flash image data.

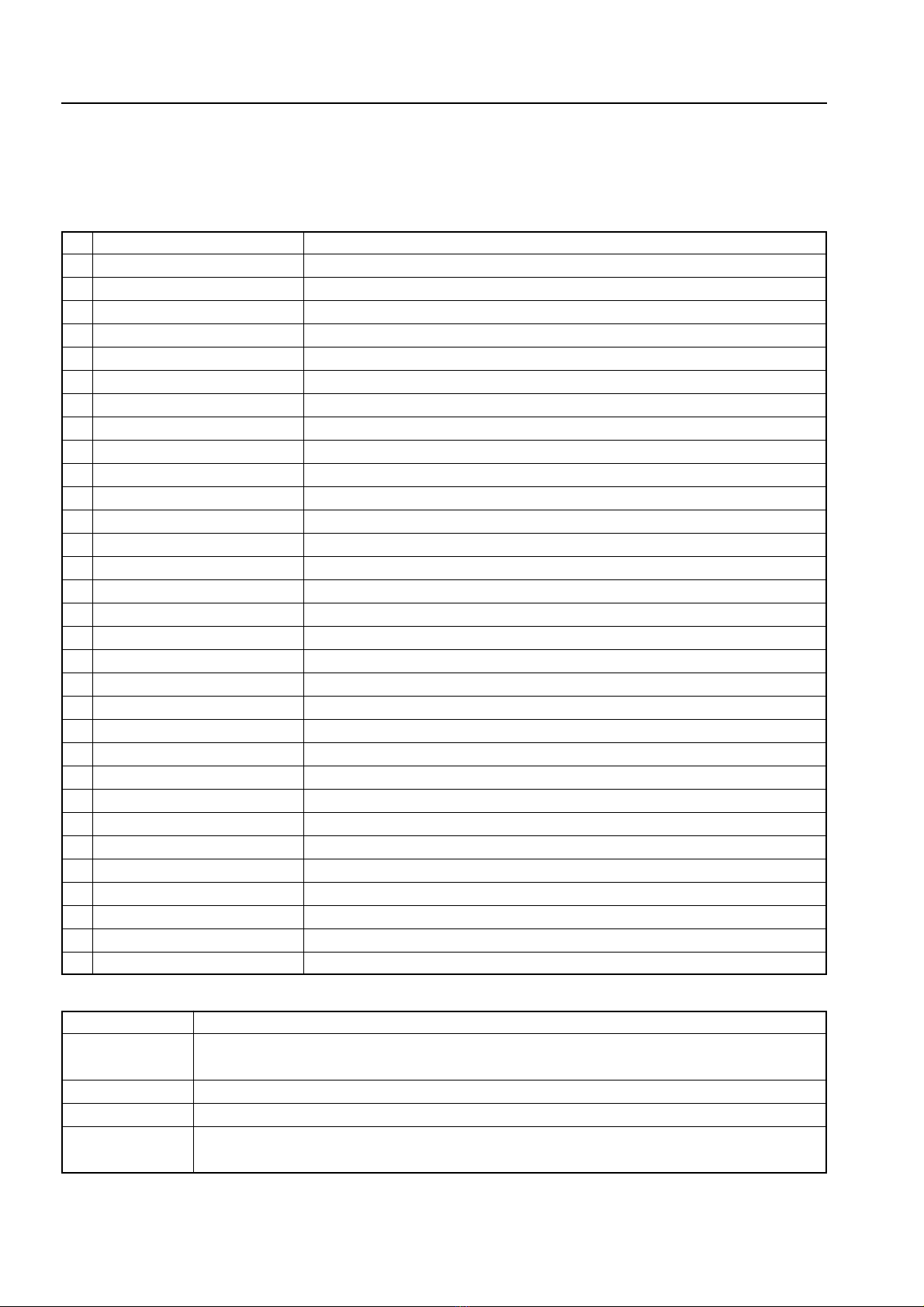

The following parts may be defective when the error log described above is generated.

Defective parts Contents of error log (Nos.1 to 31 in the table above)

Main Board Assy 1, 2, 3, 4, 5, 6, 7, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27,

28, 29, 30, 31

CCD Unit 4, 5, 6

CF 15, 20, 21, 22, 23, 29

No part defects 8 (Adjustment patterns are excessively written in the plate surface. For example, the

patterns are written so that they were painted out black.)