PriorityTM 2

Proper product installation, in accordance with these instructions, is the responsibility of the installing agent.

If you have any questions concerning these instructions, please call Kimball Office Customer Care.

2383873, Revision B

Assembly Instructions

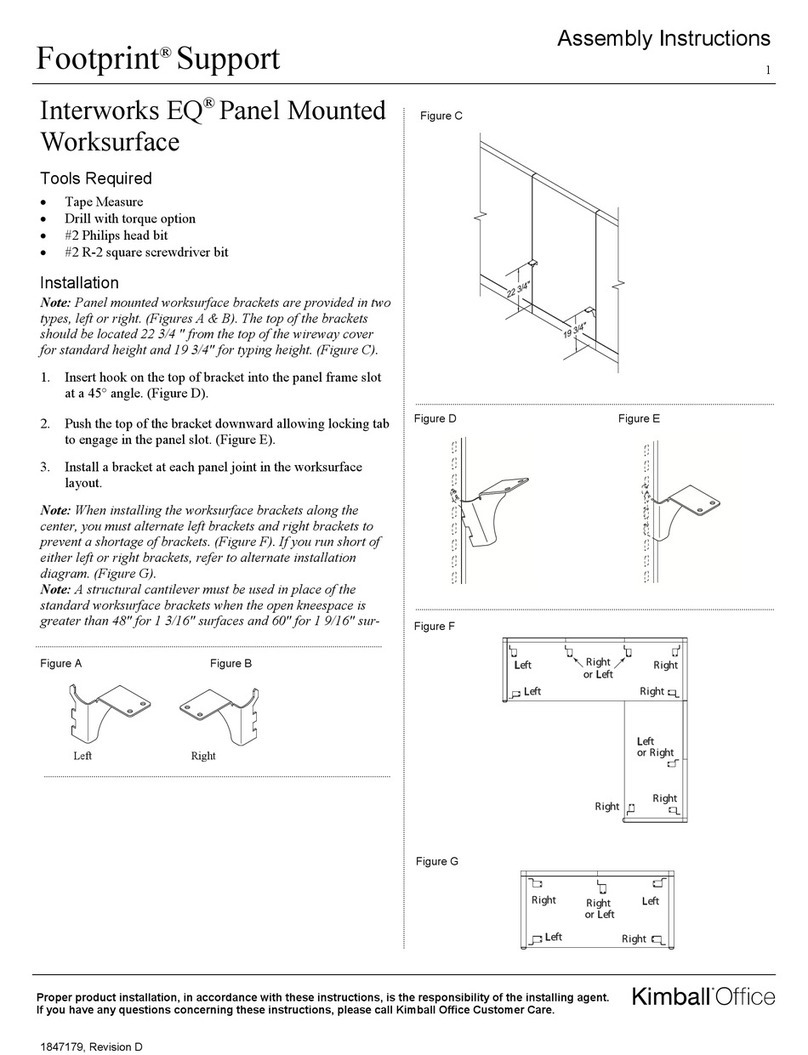

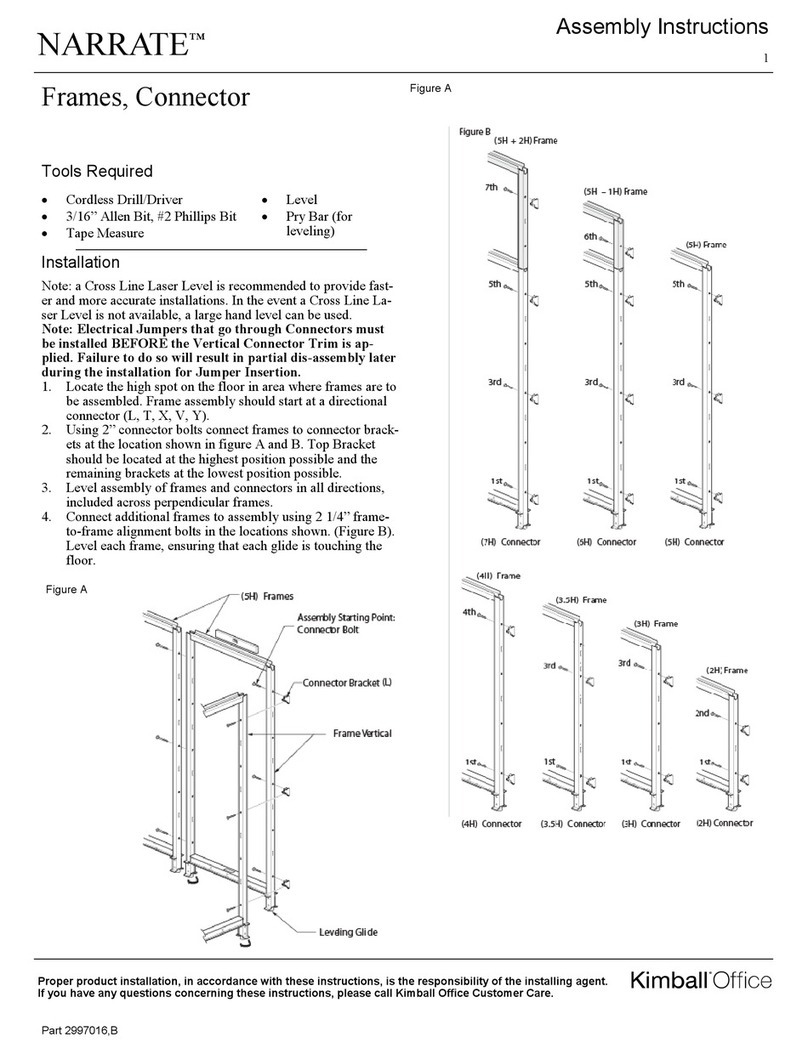

1. Support Rails are to be oriented as shown in Figure C.

2. Assembly may be done upside-down prior to connecting

Return, Extension or Bridge Frame to Main Support Rail if

preferred. (Figure B)

3. Support Rails are approximately 5” shorter than nom size.

3. Support Rails for Extensions are 12” shorter than those

that come with Returns due to Column being inset from

end of Worksurface.

4. For installing Worksurfaces to Frames or Bases, see Prior-

ity Worksurface Assembly Instructions 2383879.

5. When Worksurfaces are assembled, install Flat Brackets

(ordered separately) according to Priority Desk, Bridge

and Credenza Assembly Instructions 2008510 for each

adjoined surface.

Important: Installation of Worksurfaces is not finished

without completing item 7, and will not be properly se-

cured until doing so!

Tips

1. When installing a frame with 90” or 96” Support Rails,

first assemble smaller Support Rails with the Support Rail

Connector using M6 x 12 Socket Head Screws (12 per

Support Rail Connector), as with a Main Support Rail.

(Figure B)

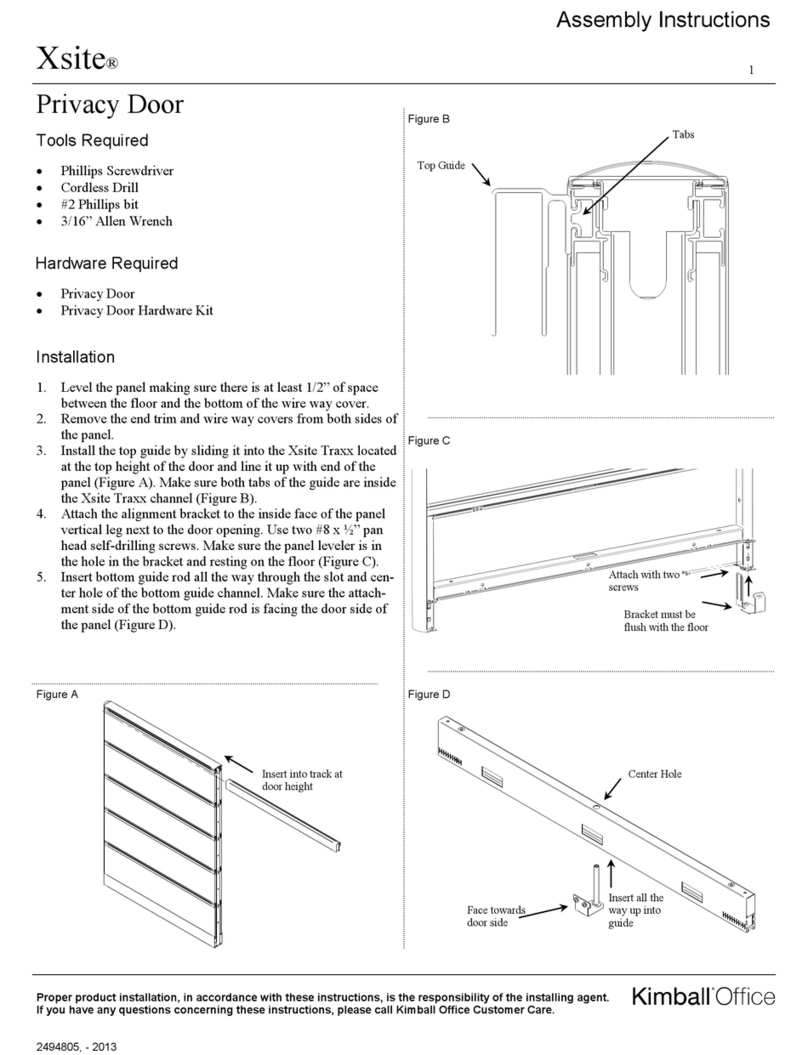

2. Attach Support Rails to Return Mounting Bracket. To en-

sure the proper holes are used during installation, begin by

aligning Guide Hole on Support Rail with appropriate mat-

ing hole on Return Mounting Bracket using M6 x 12

Socket Head Screw. Then install remaining M6 x 12

Socket Head Screws (6 per Return Mounting Bracket).

(Figures A and B)

Important: In order to determine appropriate holes to use

for proper assembly, see enlarged view. (Figure A)

Note: In order to properly connect the Return Mounting

Bracket to the Main Support Rail, the Notch shown in Fig-

ure A must first be aligned with the short flange on Main

Support Rail.

3. For Bridge Frame, repeat step 1 for opposite end.

4. Assemble Support Rails to Leg Assembly or Base. See

important installation notes for further instructions.

5. With fully assembled Return, Extension or Bridge, connect

Return Mounting Bracket to Main Support Rail with M6 x

12 Socket Head Screws (2 per Return Mounting Bracket),

using a secondary method to support the frame while

aligning holes. (Figure B) To ensure the proper holes are

used during installation, begin by aligning Guide Hole on

Return Mounting Bracket with appropriate mating hole on

Main Support Rail using M6 x 12 Socket Head Screw.

Worksurface

Support Rail

Orientation

Support Rail

(Return / Exten-

sion / Bridge)

Main Leg

Assembly or

Base

M6 x 12

Socket Head

Screw (2 per

Return

Mounting

Bracket)

Return Mounting

Bracket

Figure C

M6 x 12 Socket Head

Screw (6 per Return

Mounting Bracket)

M6 x 12 Socket

Head Screw

(12 per Support

Rail Connector)

Support Rail

Connector

(90” & 96” Support

Rails only)

Figure B

5. (continued) (Figures A and B) Then install remaining M6

x 12 Socket Head Screw.

Important: In order to determine appropriate holes to use

for proper assembly, see enlarged view. (Figure A)