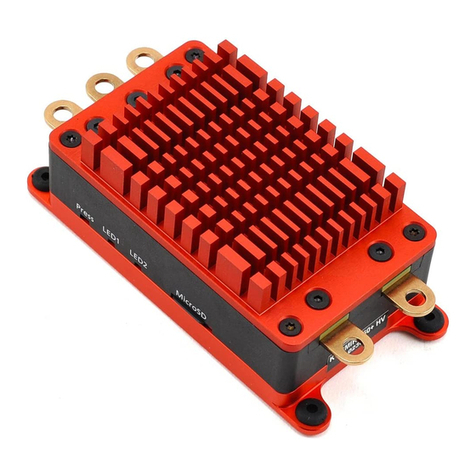

Technical data of the BEAT speed controllers

The BEAT speed Controllers are designed for brushless motors. They work without

sensors in the motor and have full part load capability. They are very sensitive and

have a soft and yet very fast start up. The built-in RPM control optimizes the app-

lication with helicopters and the mode programming helps essentially to program all

the various parameters. The Car Mode 2 allowed to drive back and forth.

BEAT controllers with BEC, 6-12 cells:

BEAT 40-6-12

40 A continuous current, 50 A for 15 sec

14 g / 33 g without / with cables - 52 x 26 x 7,5 mm

BEAT 70-6-12

70 A continuous current, 90 A for 15 sec

21g / 37 g without / with cables - 52 x 26 x 11 mm

BEAT – controllers with opto, 6-18 cells:

BEAT 40-6-18

40 A continuous current, 50 A for 15 sec

14 g / 33 g without / with cables - 52 x 26 x 7,5 mm

BEAT 55-6-18

55 A continuous current, 70 A for 15 sec

14 g / 33 g without / with cables - 52 x 26 x 7,5 mm

BEAT 80-6-18

80 A continuous current, 100 A for 15 sec

21g / 37 g without / with cables - 52 x 26 x 11 mm

BEAT FAI 7/10

150 A continuous current, 200 A for 15 sec

28g / 40 g without / with cables - 52 x 26 x 12 mm

BEAT – controllers with opto., 8-24 cells:

BEAT 40-8-24

40 A continuous current, 50 A for 15 sec

14 g / 33 g without / with cables - 52 x 26 x 7,5 mm

BEAT 60-8-24

60 A continuous current, 70 A for 15 sec

21g / 37 g without / with cables - 52 x 26 x 11 mm

BEAT FAI 24

150 A continuous current, 200 A for 15 sec

28g / 40 g without / with cables - 52 x 26 x 12 mm

BEAT – controllers with opto., 8-30 cells:

BEAT 30-8-30

30 A continuous current, 38 A for 15 sec

14 g / 33 g without / with cables - 52 x 26 x 7,5 mm

BEAT 50-8-30

50 A continuous current, 60 A for 15 sec

21g / 37 g without / with cables - 52 x 26 x 11 mm

BEAT FAI 27

100 A continuous current, 150 A for 15 sec

28g / 40 g without / with cables - 52 x 26 x 12 mm