3

INSTRUCTIONMANUAL

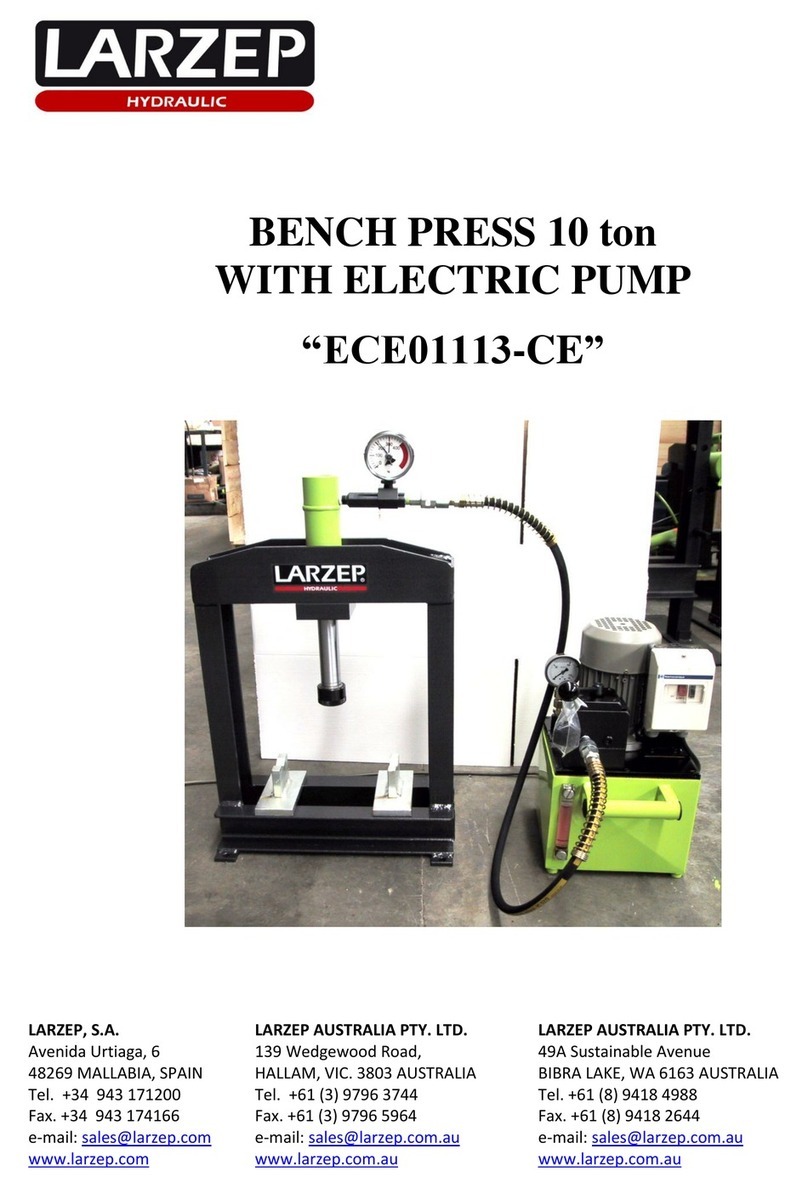

ColumnPresswithHandPump"EM06018"

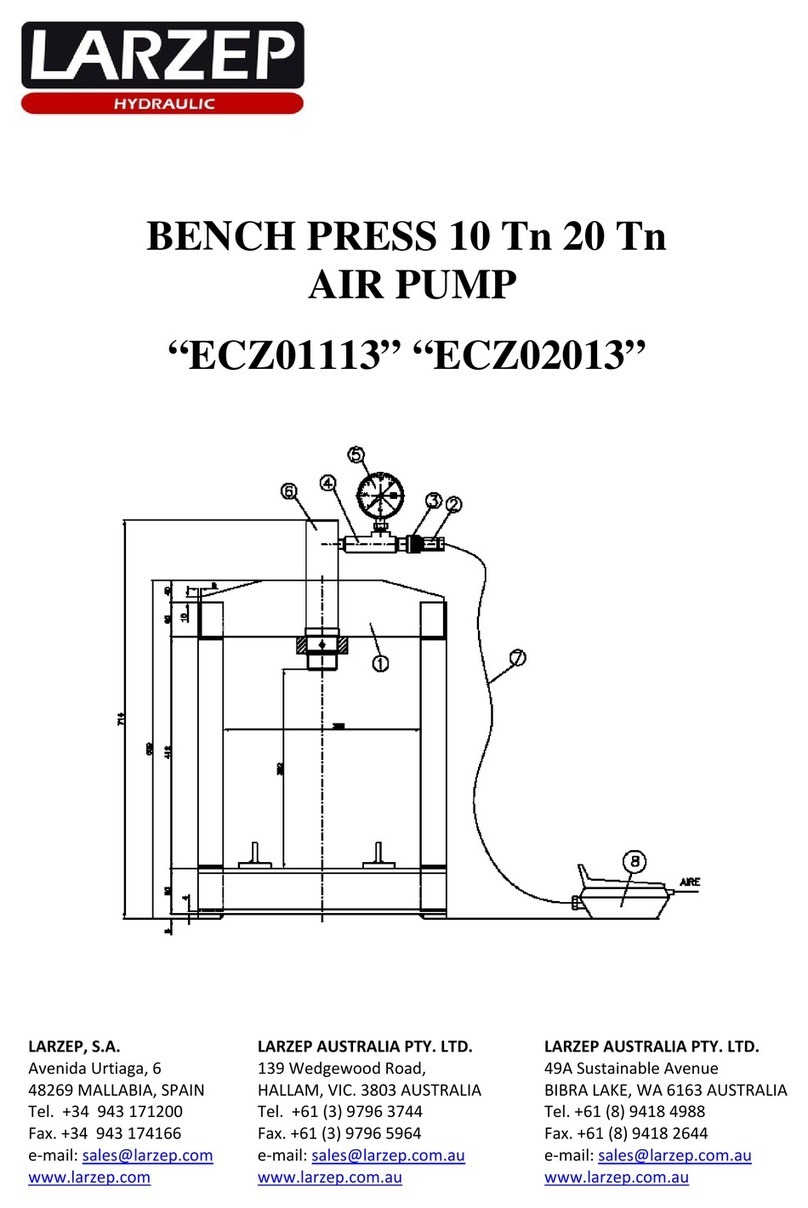

ISOLATION OF THE POWER SUPPLY: Disconnect the rapid coupler from the pump.

INFORMATION DEVICES: In the pump: Oil level and oil filling tap. In the cylinder: A gauge in order to know the operating pressure anytime.

The press, the cylinder and the pump have their corresponding serial numbers marked on them. In addition to it, you can find a sticker label showing the commercial

reference, capacity, working pressure, name and address of the manufacturer.

4. TRANSPORT AND INSTALLATION

The machine is delivered properly packed in a wooden ballet. For it’s handling, it is recommended to use a forklift truck or a crane. In the last case, it is necessary to

make the slings trespass the arc of the frame. When doing this operation, you should be cautious and prevent the flexible hoses and couplings from any damage.

The machine is stable enough to operate without fixing, but if is placed in an area commonly operated by mobile machinery (cranes, lifting equipment…) it is

strongly recommended to fix it to the desired place by drilling the supporting plates.

HYDRAULIC CONNECTION: Release the plug of the coupler; in the cylinder, and connect the hose, screwing the rapid coupler to the limit with the hand.

INSTALLING THE GAUGE

1- Replace the threaded tap in the top of the cylinder by the gauge, which is supplied separately.

2- Tighten the gauge cone to the gauge adaptor seat by using a flan wrench size 22.

3- Hold the gauge screen by hand during threading process and after reaching a comfortable reading position set the gauge screen free so that it turns the last quarter

solidarity with the thread.

CHECKING THE RIGHT OPERATION OF ALL DEVICES AND MECHANISM

Select the working maximum pressure. In manual presses 700 kg/cm2. With the hand on the lever, pump several times and check the cylinder advances.

Open the release screw of the pump and check that the cylinder piston returns by the internal spring.

To retract or stop the cylinder is necessary let the lever without movement.

Without put anything in the press, repeat the advance movement, until reaching the cylinder full stroke. In that moment the pressure will start to be increased and we

can observe it now in the gauge. This pressure will go on increasing until reaching the installation maximum pressure, previously chosen. In this stage, the cylinder

maintains the reached pressure, (the gauge maintains the reading). Check there are no leaks in the installation (gauge intake, couple, etc.)

To retract the cylinder and eliminate the installation pressure, open the release screw to the left. The piston returns by the internal spring. The return may be slower at

the end of the backstroke. Put the material to be treated in the press and act as explained regarding all the safety rules.

5. MAINTENANCE

The hydraulic circuit of the press is closed, so in normal conditions no oil leakage should be coming up. In case of oil leakage, after the proper repairing work, you

should fill up the tank with hydraulic oil by LARZEP (Ref. AZ8901); the pump is equipped with an oil level indicator to control the need quantity of oil.

As far as a non-continuous use of the press is concerned (1 hour per day), oil replacement should be done once a year.

To empty the tank, you should remove the cover and take the oil out to another container. Please, bear in mind the existing rules for waste processing when handling

the used oil. Keep greasy and lubricated the pin bearings, the piston and in general all the parts that might be in friction.

USE ONLY LARZEP HYDRAULIC OIL. Other grades of oils or types of hydraulic fluid (such as brake fluid) may affect the performance of the equipment or cause

the deterioration of the seals.

DO NO ATTEMPT TO FILL THE PUMP WITH OIL WHILE IT IS CONNECTED TO A CYLINDER WHICH IS SUSTAINING A LOAD BECAUSE IT

MAY OVERPRESSURIZE THE RESERVOIR WHEN THE PISTON RETRACS AND CAUSE DAMAGE OR INJURY

Always use the original LARZEP parts to prolong the service life of your hydraulic equipment. LARZEP S.A. or your authorized dealer can supply you with original

parts for simple maintenance work.

PROBLEMS CAUSES SOLUTIONS

1. The piston does not advance. The pump’s relief valve is open. 1. Close the relief valve.

Air is trapped in the circuit. 2. Open the pump’s relief valve; with the pump vertically (head down) pump the

several times.

No oil in the reservoir. 3. With the piston fully retracted and the pump vertically (head down) remove the

oil tank

lu

and fill it.

Dirt has accumulated in the circuit. 4. Clean the h

draulic as described in chapter 5.

Worn or damaged check valve. 5. Take the press to an authorized service dealer.

Improperl

connected line 6. With the piston full

retracted, ensure connection.

2. The piston advances in spurts. Air is entrapped in the circuit. See Solution 2.

Deformed piston. See Solution 5.

3. The piston will not fully extend. Low oil level. See Solution 3.

Deformed piston. See Solution 5.

4. The

iston advances slowly. Air is entrapped in the circuit. See Solution 2.

Dirt has accumulated in the circuit. See Solution 4.

Worn or dama

ed check valve. See Solution 5.

Improperly connected line See Solution 6.

6. WARRANTY

LARZEP, S.A. guarantees its products against all design and manufacturing defects for the durations of two years from the date of purchase. This guarantee does not

include the ordinary wear of both metal and non-metal parts, abuse, using the equipment beyond its rated capacity and any wear or damage incurred as a result of using

a hydraulic fluid which is not recommended by LARZEP, S.A.

Please note that if the equipment is disassembled or serviced by anyone other than an authorized service dealer or by LARZEP, S.A., this guarantee is rendered null

and void.

In the event of a warranty claim, return the equipment, to LARZEP, S.A. or the authorized dealer which sold you the hydraulic equipment, LARZEP, S.A. will repair

or replace the faulty equipment, whichever is deemed most appropriate. LARZEP, S.A. shall not be held liable for any consequential damages or losses, which may

occur as a result of faulty equipment