4

INSTRUCTIONMANUAL

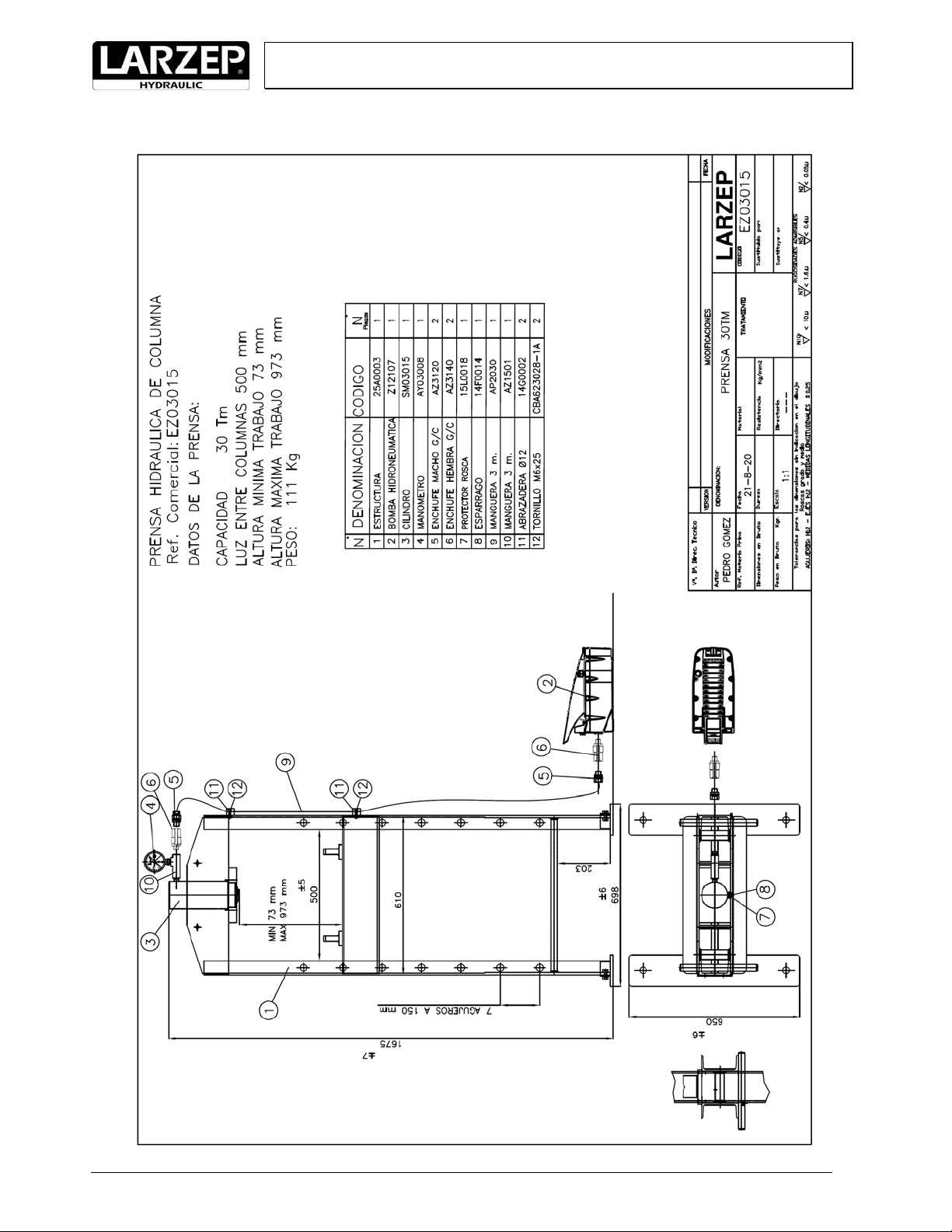

ColumnPresswithHydropneumaticPump"EZ03015"

3. TRANSPORT AND INSTALLATION

The machine is delivered properly packed in a wooden pallet. For its handling, it is recommended to use a forklift truck or a crane. In the last case, it is necessary

to make the slings trespass the arc of the frame. When doing this operation, you should be cautious and prevent the flexible hoses and coupling from any damage.

The machine is stable enough to operate without fixing, but if it is placed in an area commonly operated by mobile machinery (cranes, lifting equipment...) it is

strongly recommended to fix it to the desired place by drilling the supporting plates.

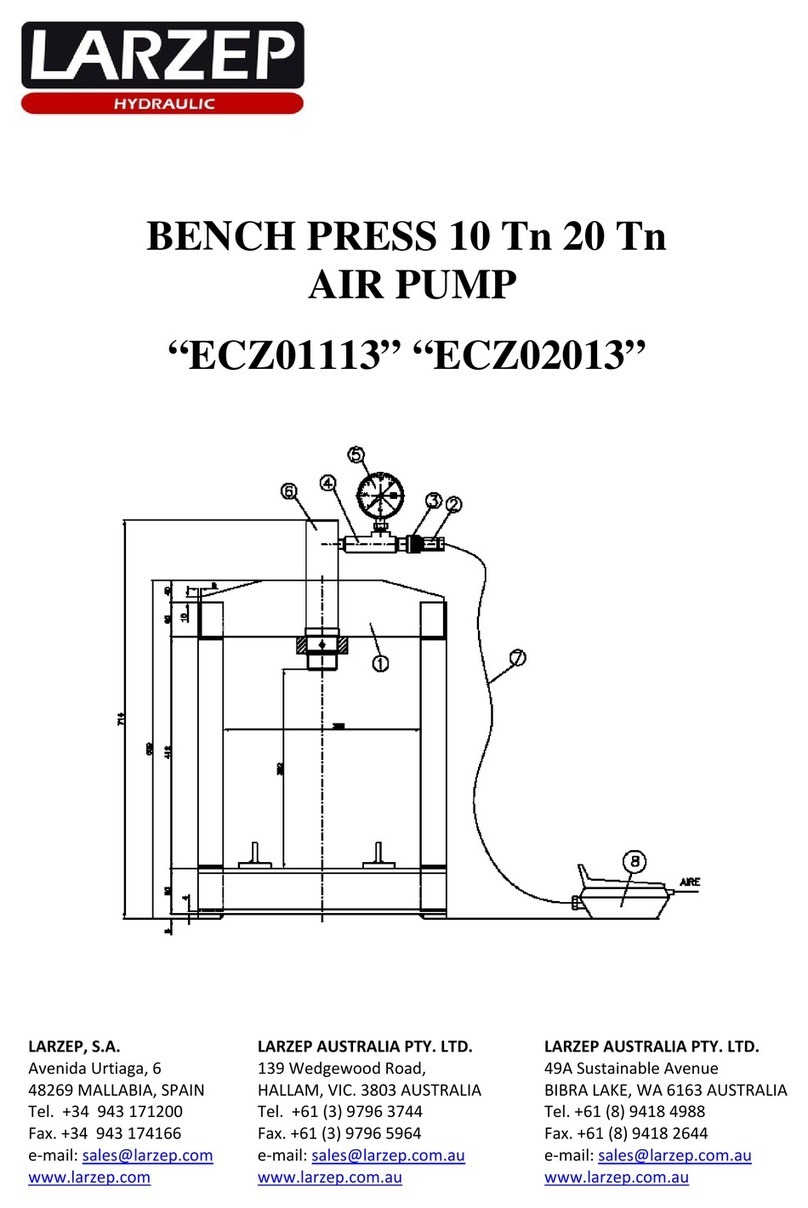

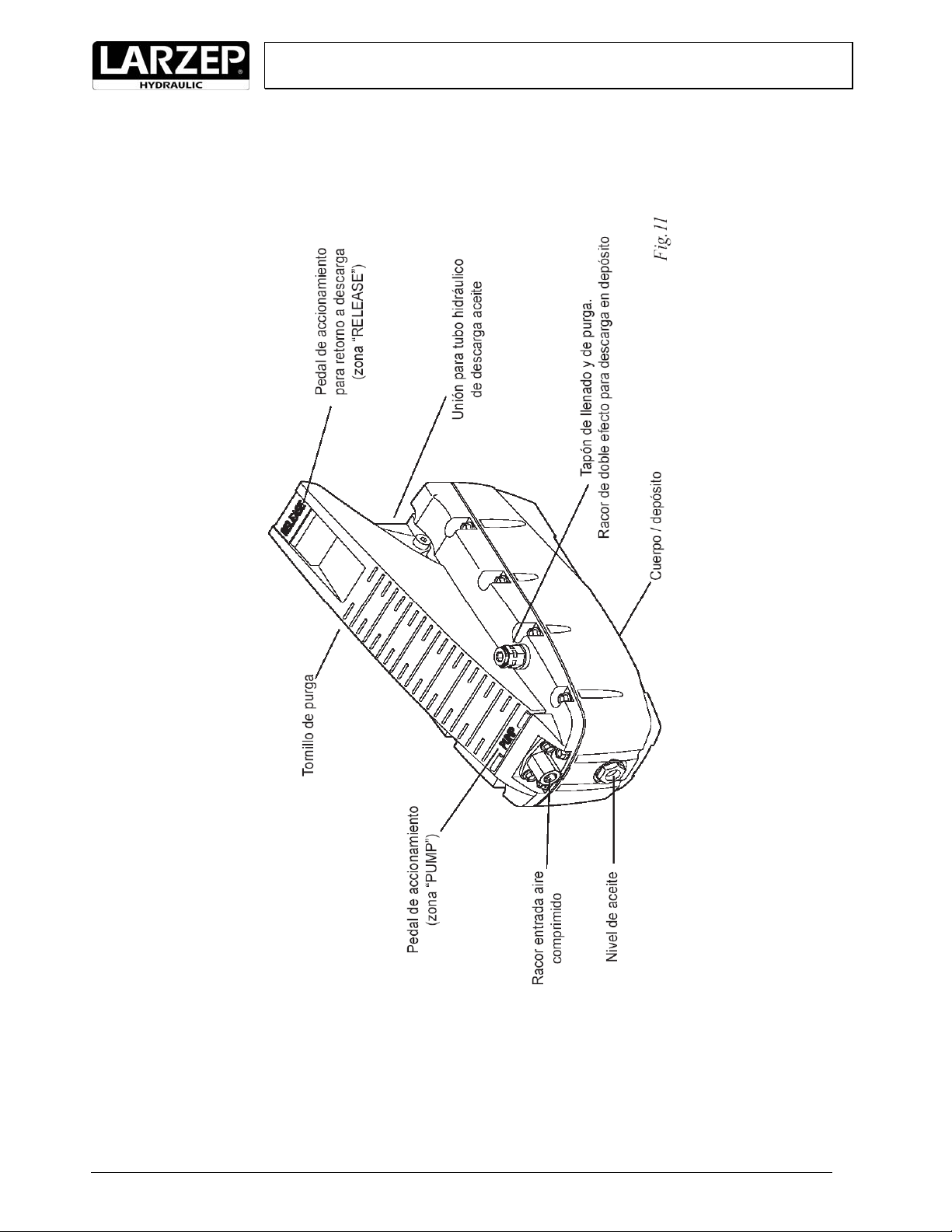

HYDRAULIC CONECTION

Remove the cap of the rapid coupling from the cylinder exit and connect the hose, threading the rapid coupling until the end with the hand.

REPLACEMENT OF THE TRANSPORT CAP

You should replace the a.m. cap on the tank cover by the pressurized cap supplied with the press (in the small plastic bag next to the lever of the distributor).

INSTALLING THE GAUGE

Replace the threaded tap in the top of the cylinder by the gauge which is supplied separately. Tighten the gauge cone to the gauge adaptor seat by using a flat

wrench size 22. Hold the gauge screen by hand during threading process and after reaching a comfortable reading position set the gauge screen free so that it turns

the last quarter solidarily with the thread.

There is an alternative gauge port in the electric pump with a 3/8" BSP thread.

PNEUMATIC CONECTION

Connect the pump pedal to the air compressed net.

Assure that the foot is not pushed.

CHECKING THE RIGHT OPERATION OF ALL DEVICES AND MECHANISM

1. Select the maximum working pressure.

2. Put operator foot in the pump pedal.

3. Push the start-up foot.

4. Check that the cylinder is pushed.

5. Check that the cylinder piston goes back pushed by the internal spring. In both cases, to maintain the movement is necessary to push the pedal.

6. Without put anything in the press, repeat the push movement, pushing until reaching the cylinder full stroke (150 mm). In that moment the pressure

will start to be increased and we can observe it now in the gauge. This pressure will go on increasing until reaching the installation maximum pressure,

previously chosen. In this stage, the cylinder maintains the reached pressure (the gauge maintains the reading). Check there are no leaks in the

installation (gauge intake, coupling, etc…).

7. To retract the cylinder and eliminate the installation pressure push the pedal. The piston retracts pushed by the internal spring.

8. Put the material to be treated in the press.

Once all the steps have been completed, the machine is ready to be used. Repeat the sequence as many times as required to get the knowledge on how to work the

machine.

4. START-UP

Operate the machine as per the previously mentioned indications.

Regulation of the maximum working pressure

The maximum pressure developed by the hydraulic system is 700 kg/cm2. An internal security valve discharges when the system reaches that pressure.

5. MAINTENANCE

The hydraulic circuit of the press is closed, so in normal conditions no oil leakage should be coming up.

In case of oil leakage, after the proper repairing work, you should fill up the tank with hydraulic oil by LARZEP (Ref: AZ8902). The electric pump is equipped

with an oil level indicator to control the need quantity of oil.

As far as a non-continuous use of the press is concerned (1 hour per day), oil replacement should be done once a year. To empty the tank, you should remove the

cover and take the oil out to another container. Please, bear in mind the existing rules for waste processing when handling the used oil.

Keep greasy and lubricated the pin bearings, the piston and in general all the parts that might be in friction.

IMPORTANT: In case of working with pressures superior to 400kg/cm², substitute the given gauge by one suitable for the