5

INSTRUCTION MANUAL

Bench Press with Air Pump

PARTS TO INSPECT

In a FREQUENT INSPECTION, check for:

•Piston wear

•Signs of corrosion

•Wear or damage to the cylinder or pump

•Cracks, dents or any other damage to the frame, cylinder attachments, work table and its supports

•Oil leaks

•Loose or damage screws or joints

•Damaged or incorrectly assembled accessories

In a PERIODIC INSPECTION, check for the same problems as in a frequent inspection but in addition, the hydraulic equipment should be disassembled and cleaned

by an authorized service dealer so that it may be examined internally.

Periodically clean and relubricate the press’s moving parts, such as the piston, winch, pumping mechanism, etc. This is especially important when working in salty or

humid environments.

Hydraulics equipment, which is subject to the very severe environmental conditions mentioned, previously should be cleaned and relubricated after each use.

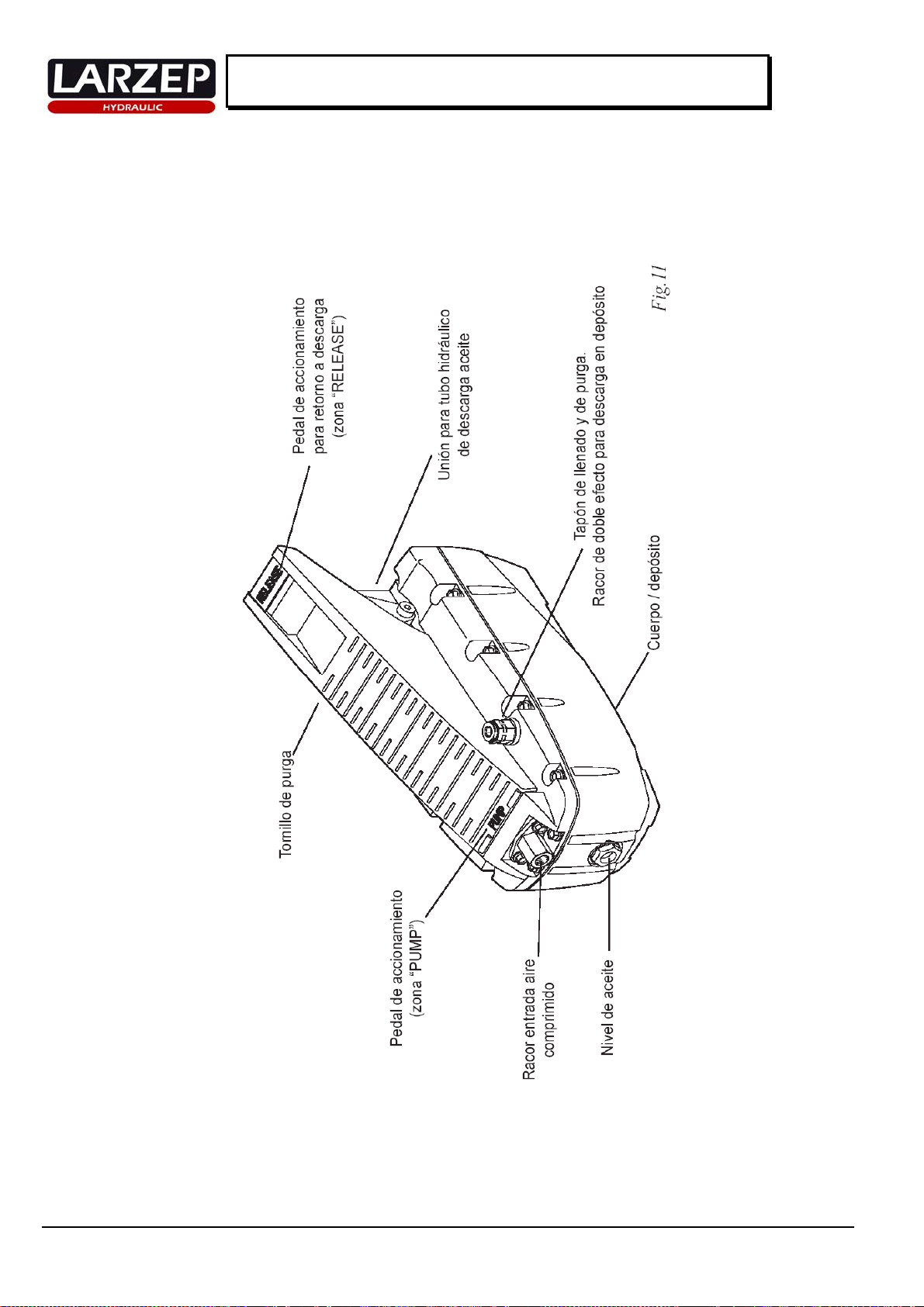

To clean the hydraulic equipment, begin by removing the pump’s oil reservoir plug and draining al the oil. Fill reservoir with kerosene and thoroughly circulate it

thorough the hydraulic equipment. After completely purging the kerosene out of the hydraulic circuit, align the pump vertically with the head down and fill the

reservoir with the new hydraulic oil until the oil level rises to the orifice

USE ONLY LARZEP HYDRAULIC OIL

Other grades of oils or types of hydraulic fluid (such as brake fluid) may affect the performance of the equipment or cause the deterioration of the seals.

Always use the original LARZEP parts to prolong the service life of your hydraulic equipment. LARZEP S.A. or your authorized dealer can supply you with original

parts for simple maintenance work.

6. PROBLEMS, CAUSES AND SOLUTIONS.

PROBLEMS POSSIBLE FAILLURES SOLUTION

1. The piston does not advance. - Prime less pump. 1. Feed the pump keeping it started some minutes.

- Dirty accumulated in the filter. 2. Extract and clean it.

-No oil in the reservoir. 3. Check the level.

- Cylinder pressure retainer damaged. 4. Replace the retainer.

-Directional valve damaged.

5. Replace the valve.

- Cylinders body damaged. 6. Repair the body of the cylinder.

- Pneumatic problem. 7.Check the installation.

2. The cylinder does not reach pressures. - Pressure relief valve unrated. 8. Rate the valve.

- Cylinder pressure retainer damaged. See Solution. 4.

- Cylinders body damaged. See Solution. 6.

3. The cylinder does not maintain pressure. - Cylinder pressure retainer damaged. See Solution. 4.

- Directional valve damaged. See Solution. 5.

4. The cylinder does not retract. - Damaged return spring. 9. Replace the spring.

- Directional valve damaged. See Solution. 5.

The solutions marked in black must be carried out by specialized personnel, for it, go to an authorized distributor that sold you the equipment or to LARZEP, S.A., we

have original spare part kits as well as the necessary personnel, do not doubt in contacting to us, we are to yours disposition.

Always use original spare parts LARZEP, you will extend the life utility of the equipment, in opposite case the company will not become person in charge of the

possible failures, damages or losses that take place.

7. WARRANTY.

LARZEP, S.A. guarantees its products against all design and manufacturing defects for the durations of two years from the date of purchase. This guarantee does not

include the ordinary wear of both metal and non-metal parts, abuse, using the equipment beyond its rated capacity and any wear or damage incurred as a result of using

a hydraulic fluid which is not recommended by LARZEP, S.A.

Please note that if the equipment is disassembled or serviced by anyone other than an authorized service dealer or by LARZEP, S.A., this guarantee is rendered null

and void.

In the event of a warranty claim, return the equipment, to LARZEP, S.A. or the authorized dealer which sold you the hydraulic equipment, LARZEP, S.A. will repair

or replace the faulty equipment, whichever is deemed most appropriate. LARZEP, S.A. shall not be held liable for any consequential damages or losses, which may

occur as a result of faulty equipment

DO NO ATTEMPT TO FILL THE PUMP WITH OIL WHILE IT IS CONNECTED TO A CYLINDER WHICH IS SUSTAINING A LOAD

BECAUSE IT MAY OVERPRESSURIZE THE RESERVOIR WHEN THE PISTON RETRACS AND CAUSE DAMAGE OR INJURY