1!USEFUL'INFORMATION' 6!

1.1!PURCHASE'INVOICE'AND'WARRANTY' 6!

1.2!SUPPORT'INFORMATION' 7!

1.3!WHAT'IS'IN'THE'BOX' 7!

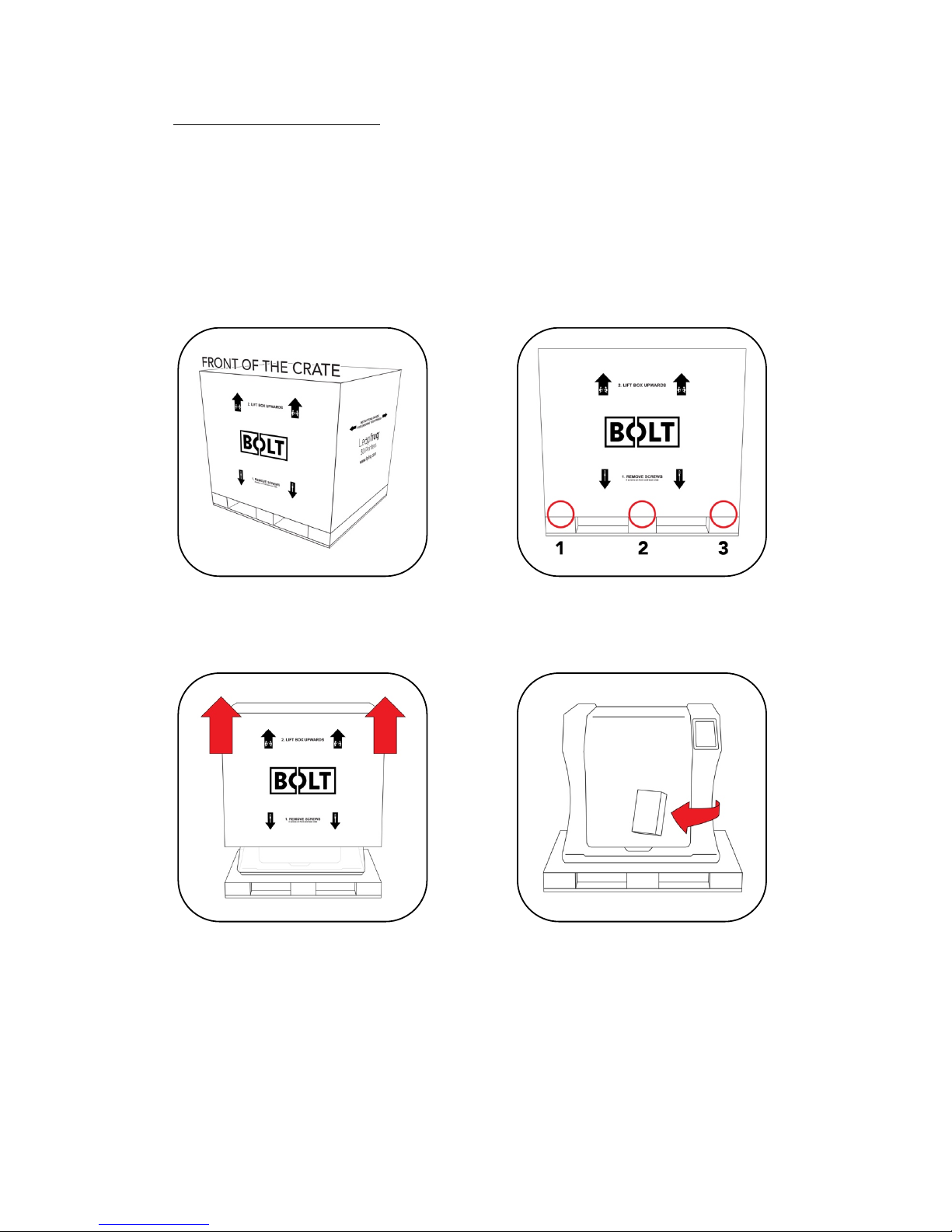

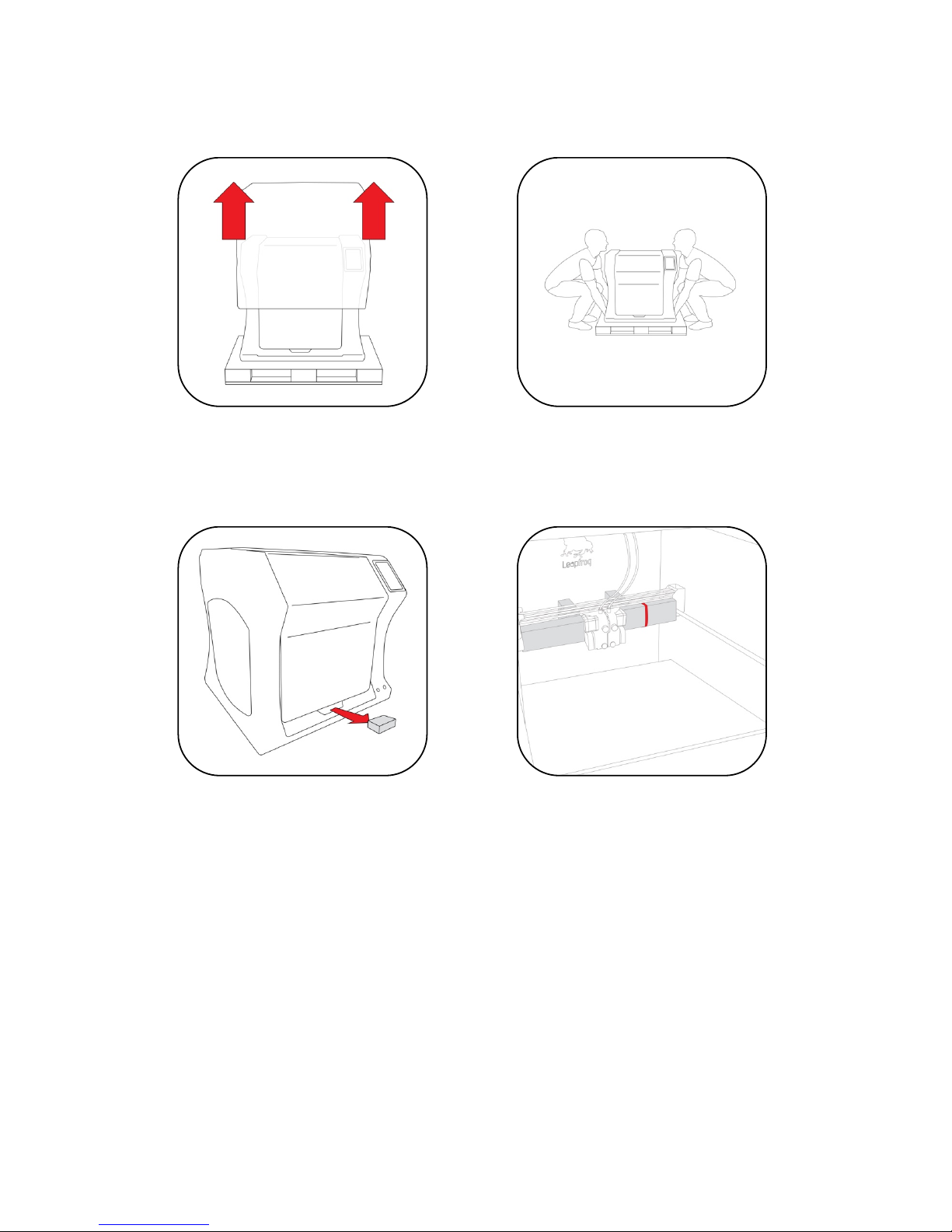

1.4!UNBOXING'THE'PRINTER' 8!

1.5!ELECTRIC'POWER'CORD'COMPATIBILITY'11!

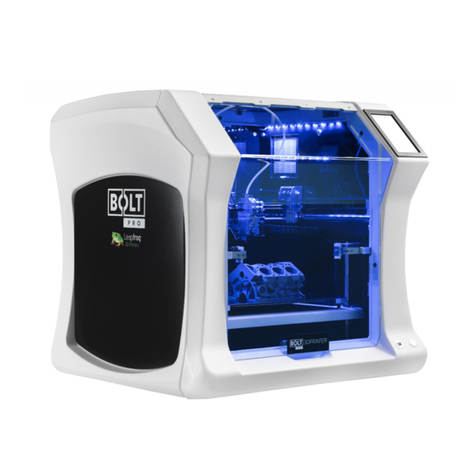

2!ABOUT'THE'BOLT'12!

2.1!BOLT'OVERVIEW'12!

2.2!BOLT'SPECIFICATIONS'13!

2.3!LEAPFROG'USER'INTERFACE'OVERVIEW'15!

3!PRINTER'SETUP'19!

3.1!SETTING'UP'ADMIN'AND'USER'ACCOUNTS'20!

3.2!CONNECTING'THE'BOLT'21!

3.3!AUTOMATIC'UPDATE'FUNCTION'22!

3.4!CALIBRATE'PRINT'BED'22!

3.5!LOADING/UNLOADING'FILAMENT'23!

3.6!ADD'MATERIAL'28!

3.7!ADHESIVE'MATERIAL'28!

4!PRINTING'29!

4.1!STARTING'PRINT'JOBS'29!

4.2!FINISHING'PRINT'JOBS'31!

4.3!USING'DIFFERENT'PRINTING'MODES'32!

4.4!INFORMATION'AVAILABLE'ON'PRINT'JOBS'33!

4.5!ACCESSING'AND'UPLOADING'PRINT'JOBS'34!

5!CREATING'A'PRINTFILE'35!

5.1!CREATR'POWERED'BY'MATERIALISE'36!

5.2!PRINTER'SELECTION'36!

5.3!IMPORT'36!

5.4!TRANSFORM'37!

5.5!SELECT'NOZZLE'37!

5.7!PREVIEW'AND'GENERATE'G-CODE'39!

6!LEAPFROG'USER'INTERFACE'40!

6.1!LEAPFROG'USER'INTERFACE'FEATURES'40!

6.2!REMOTE'ACCESS'40!

6.3!CONNECTION'THE'BOLT'USING'YOUR'NETWORK'41!

6.4!USING'THE'WEBCAM'42!

6.5!PURGE'NOZZLES'42!

6.6!MATERIALS'42!

7!PRINT'SETTINGS'44!