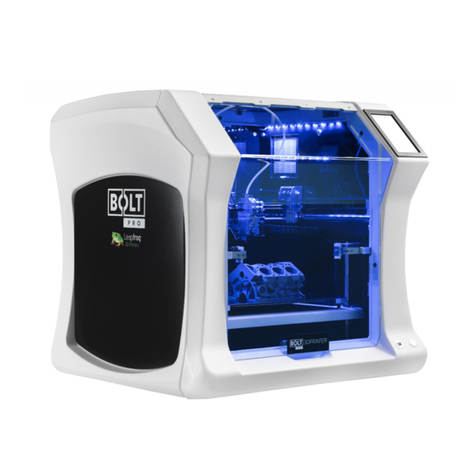

LeapFrog Bolt PRO User manual

Other LeapFrog 3D Printer manuals

LeapFrog

LeapFrog BOLT User manual

LeapFrog

LeapFrog BOLT User manual

LeapFrog

LeapFrog Creatr HS User manual

LeapFrog

LeapFrog Xeed User manual

LeapFrog

LeapFrog BOLT User manual

LeapFrog

LeapFrog Creatr HS User manual

LeapFrog

LeapFrog Xeed User manual

LeapFrog

LeapFrog Creatr HS User manual

LeapFrog

LeapFrog Bolt PRO User manual

LeapFrog

LeapFrog 3d printer User manual