1 CMVCAN01B

Contents

1 Safety Information .............................................................................................................2

1.1 Warnings, Cautions and Notes ......................................................................................... 2

1.1.1 General ...............................................................................................................................2

1.1.2 Application ..........................................................................................................................2

1.1.3 Installation ..........................................................................................................................2

1.1.4 Electrical Connection ..........................................................................................................2

1.1.5 Operation ............................................................................................................................3

1.2 Reference Documentation ................................................................................................ 3

2 Introduction .......................................................................................................................4

2.1 Overview ........................................................................................................................... 4

2.2 SMVector CANopen Implementation Specifications ......................................................... 4

2.3 Module Identification Label ............................................................................................... 4

3 Installation .........................................................................................................................5

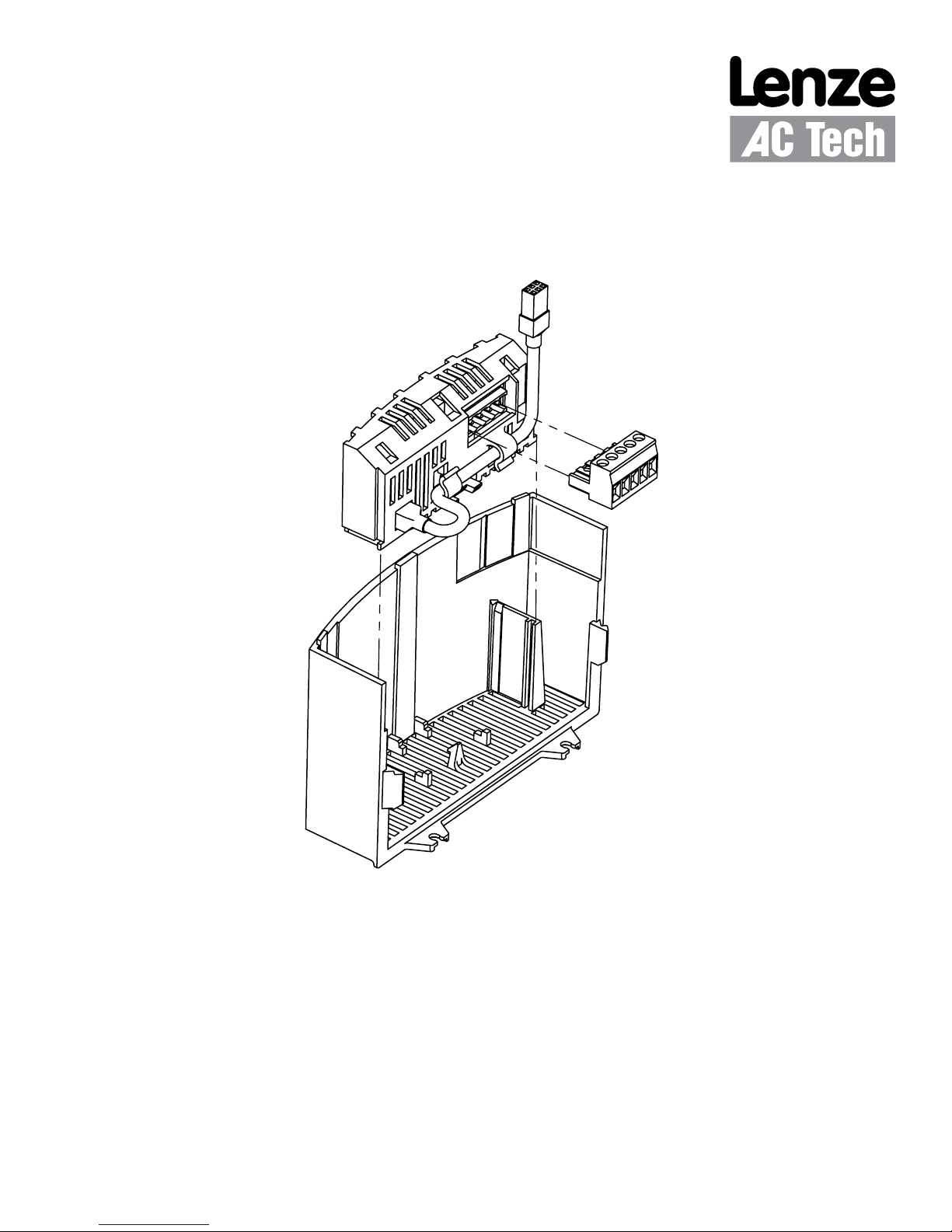

3.1 Mechanical Installation ...................................................................................................... 5

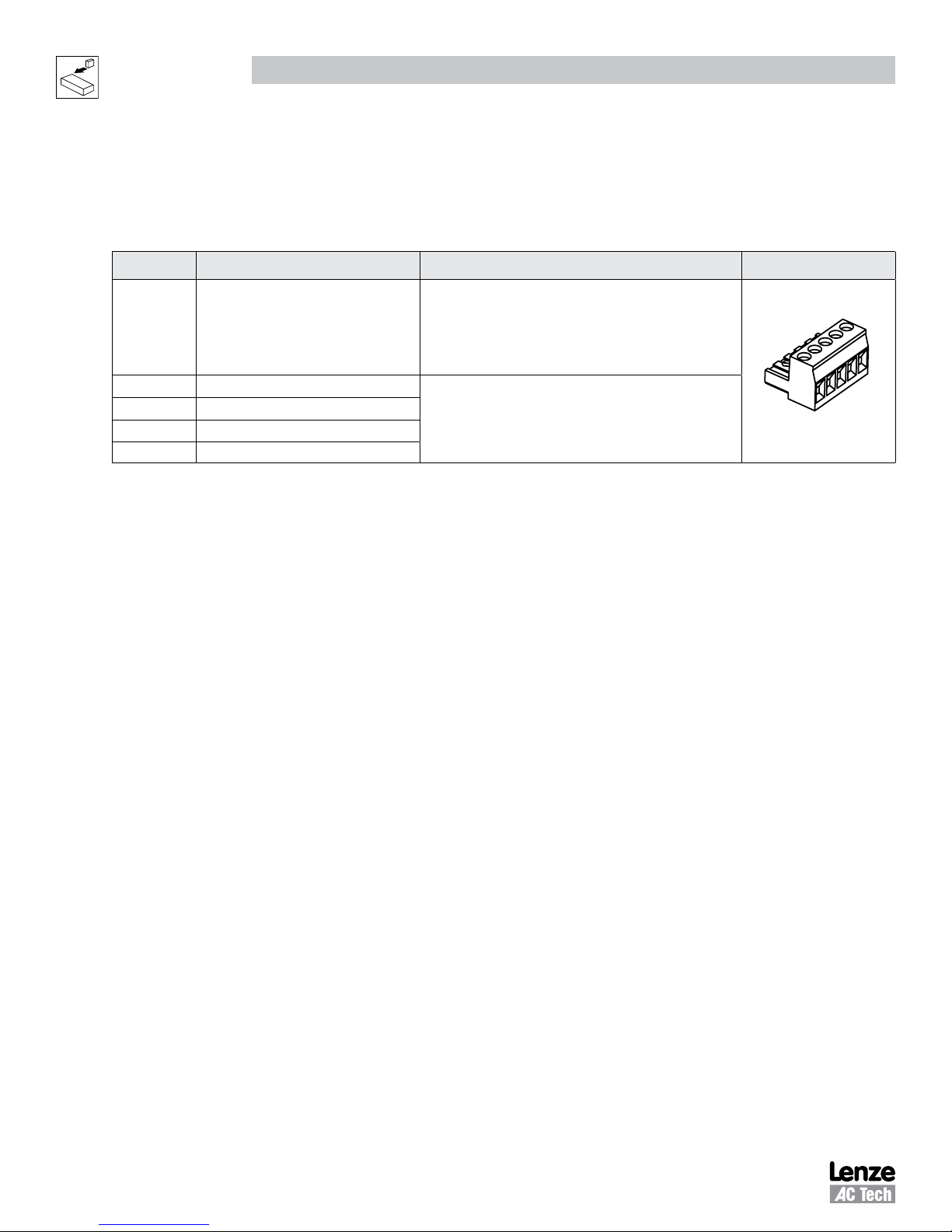

3.2 CANopen Terminal Block .................................................................................................. 6

3.3 Electrical Installation ......................................................................................................... 6

3.3.1 Cable Types .......................................................................................................................6

3.3.2 Network Limitations ............................................................................................................6

3.3.3 Connections and Shielding .................................................................................................7

3.3.4 Network Termination...........................................................................................................8

3.3.5 Network Schematic .............................................................................................................8

4 Commissioning CANopen Communications .....................................................................9

4.1 Quick Set-up ..................................................................................................................... 9

5 Extended Parameters for CANopen ...............................................................................10

5.1 Parameter Menu ............................................................................................................. 10

5.2 CANopen Mapping Details .............................................................................................. 17

5.2.1 RPDO Mapping (P446/P456) ...........................................................................................17

5.2.2 TPDO Mapping (P466/P476) ............................................................................................20

6 Troubleshooting and Fault Elimination ...........................................................................23

6.1 Faults .............................................................................................................................. 23

6.2 Troubleshooting .............................................................................................................. 23

A1 Appendix A - Configuration Example ..............................................................................24

A1.1 Master / Follower Drive System ...................................................................................... 24