Contentsi

l8 BA 12.0023−EN 6.0

1 Preface and general information 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 About these Operating Instructions 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Terminology used 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Scope of supply 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Lenze drive systems 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 Labelling 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Legal regulations 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Personnel responsible for safety 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 General safety information 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Notes used 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Technical data 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

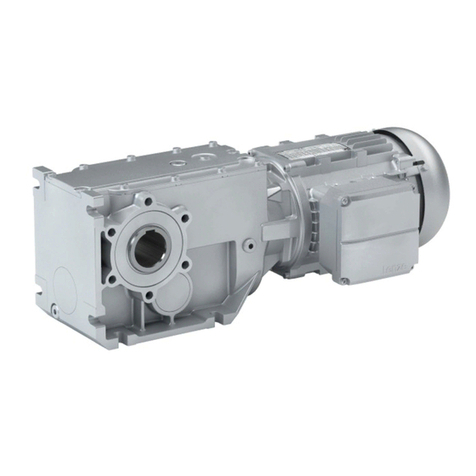

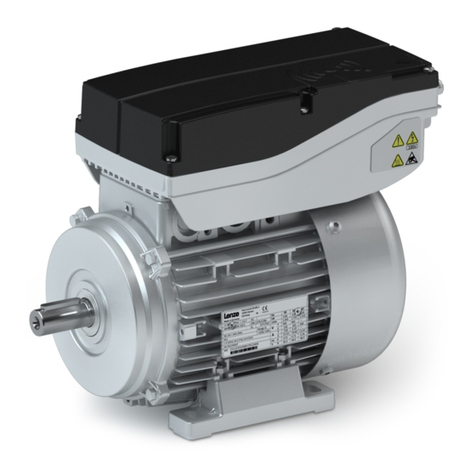

3.1 Product features 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Transport weights 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 General data and operating conditions 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Temperatures 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Ambient conditions 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Paint 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Mechanical installation 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Transport equipment for gearbox 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Storage 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Backstop 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Mounting 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Preparation 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 General information about the assembly of drive systems 22. . . . . . . . . . .

4.4.3 Assembly of transmission elements on solid shafts 22. . . . . . . . . . . . . . . .

4.4.4 Attachment of motors to gearboxes with bearing housing

(input design N) 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.5 Coupling hubs 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.6 Attachment of gearboxes with hollow shafts and keyway 27. . . . . . . . . .

4.4.7 Mounting the shrink disc with a rotating cover 29. . . . . . . . . . . . . . . . . . . .

4.4.8 Mounting the fixed cover 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.9 Mounting the hoseproof hollow shaft cover 34. . . . . . . . . . . . . . . . . . . . . .

4.4.10 Gearboxes with breathers 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.11 Breather position, oil filling screw and drain plug 36. . . . . . . . . . . . . . . . . .

4.4.12 Gearbox with compensation container for mounting position C 48. . . . .