Product informaon

Product descripon

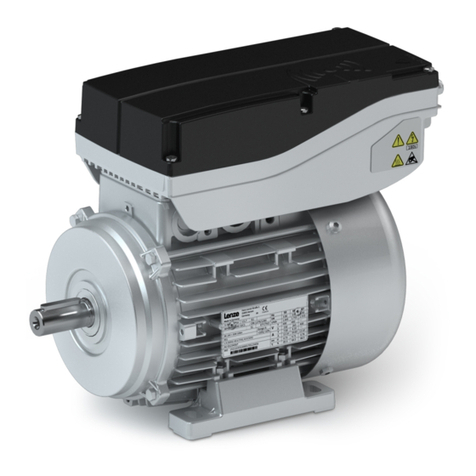

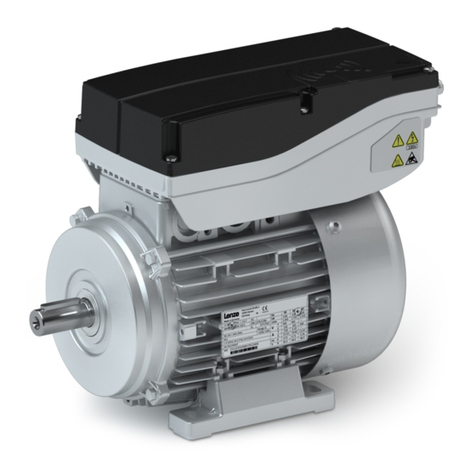

The new freedom in moon for engineers. Lenze Smart Products reduce the number of

dierent drives by up to 70 %. Without contactor and starter, with freely adjustable xed

speeds and many integrated funcons for technical material-handling applicaons. The Lenze

Smart motor also fulls the highest requirements regarding energy eciency and can be

conveniently operated by means of a smart phone.

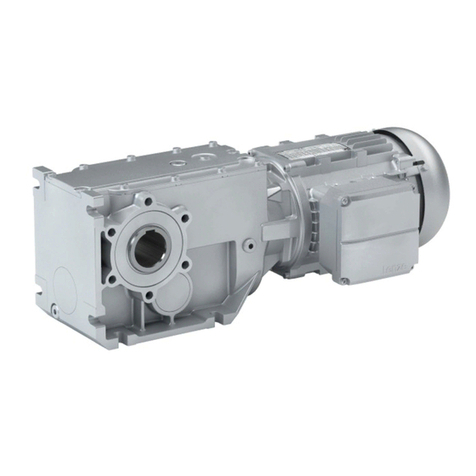

When used in combinaon with three-phase AC motors, our bevel gearboxes form a compact,

powerful drive unit. Numerous opons at the input and output end provide for the drive to be

exactly adapted to your applicaon.

The ecient bevel gearboxes are characterized by high permissible radial forces, closely

stepped raos and a low backlash. They are available in a 2-, 3- and 4-stage design with a

torque of up to 4300 Nm and a rao of up to i= 3167.

Versions

•High-ecient right-angle gearbox in a compact design for space-saving installaon

•Market standard sha dimensions and standardized anges for easy machine integraon

•Low backlash and high torsional rigidity during posioning provide for exact results

Reducon in the number of variants made easy

Before now, dierent output speeds (e. g. for dierent conveying speeds) were enabled by

dierent gearbox raos or, in the case of very large dierences, by means of the number of

pole pairs of the motors. This led to a large number of dierent drive variants..

Things are dierent with the Lenze Smart Products: Due to the possibility of freely adjusng

the motor speed within a vefold adjustment range at a constant torque, very dierent

speeds can be enabled with one single drive variants. The cost and eort involved in design,

selecon, procurement and storage are thus reduced considerably.

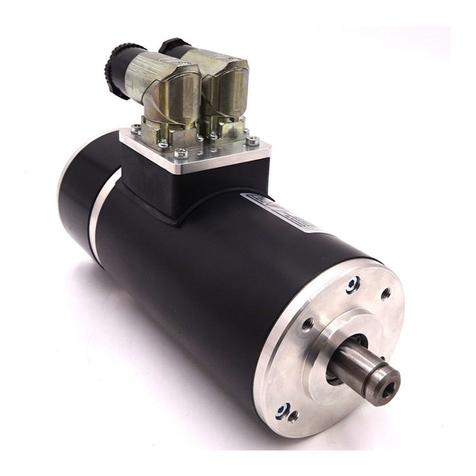

Fig. 1: MSEMAXX080-32 Smart Motor - g500-B450 bevel gearbox

Easy adjustment

NFC technology (NFC = Near Field Communicaon) is used to adapt the Lenze Smart Products

to the applicaon as well as for diagnoscs). The drive can be adjusted very easily without

opening the terminal box. without voltage supply and without me-consuming addressing.

Only an NFC-capable Android smartphone or the Lenze NFC adapter for PCs is needed as a

tool. The data can therefore be read and wrien when the drive is in a de-energised state –

via password protecon, of course.

Product informaon

Product descripon

7