Life Fitness Elliptical X5i User manual

Other Life Fitness Fitness Equipment manuals

Life Fitness

Life Fitness Base X1 User manual

Life Fitness

Life Fitness E5 User manual

Life Fitness

Life Fitness 95SE User manual

Life Fitness

Life Fitness SIGNATURE Series User manual

Life Fitness

Life Fitness Lifecycle 5500HR User manual

Life Fitness

Life Fitness Essential XT4 User manual

Life Fitness

Life Fitness GO CONSOLE User manual

Life Fitness

Life Fitness 91XW-0XXX-01 User manual

Life Fitness

Life Fitness Exercise Bike Lifecycle 8500 User manual

Life Fitness

Life Fitness Muti Jungle Handle Accessory Rack MJHAR User manual

Life Fitness

Life Fitness 90S User manual

Life Fitness

Life Fitness 95XE-0XXX-01 User manual

Life Fitness

Life Fitness 8500 Rower User manual

Life Fitness

Life Fitness X9 User manual

Life Fitness

Life Fitness CLUB SERIES SHROUD KIT 64 Inch User manual

Life Fitness

Life Fitness 95XW-0XXX-02 User manual

Life Fitness

Life Fitness 8110 User manual

Life Fitness

Life Fitness M051-00K62-B095 User manual

Life Fitness

Life Fitness LCD Entertainment Ready User manual

Life Fitness

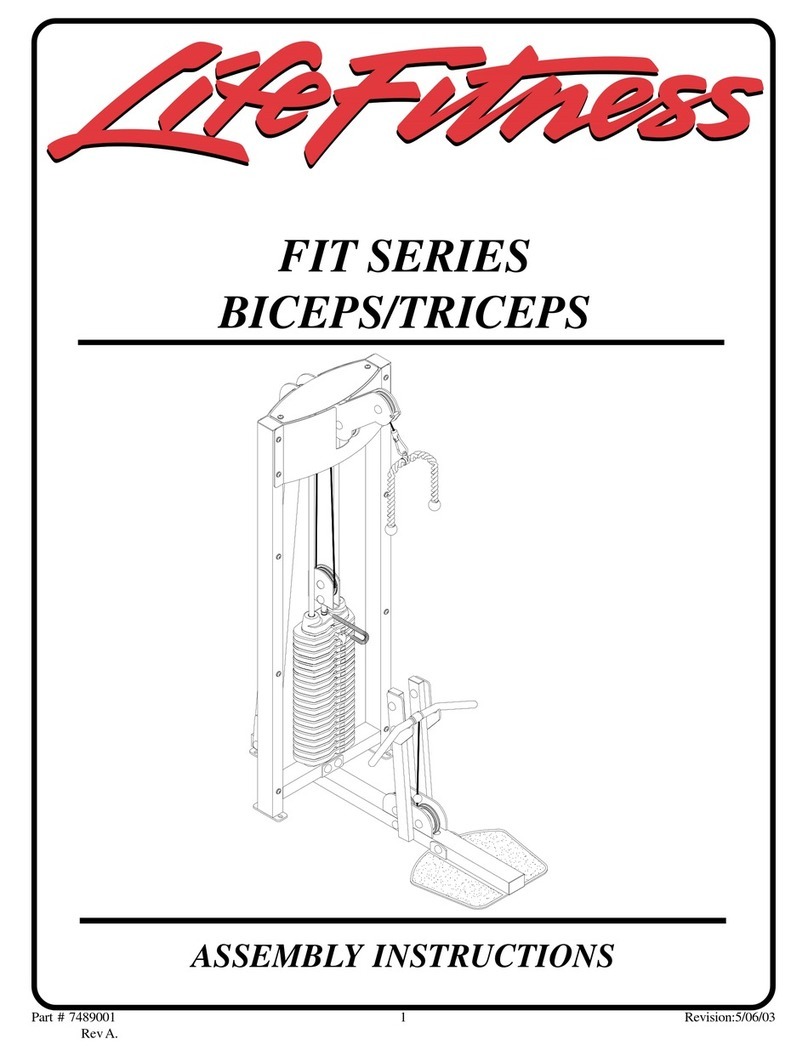

Life Fitness FIT SERIES User manual