Lighthouse REMOTE 3014P, 5104P Operating Manual

t-ii 248083336-1 Rev 3

Power Switch ................................................................................................... 3-11

Optional Analog Input Ports ............................................................................ 3-11

Remote Display Connector .............................................................................. 3-11

Peripheral Interface Connector .................................................................................... 3-12

Data .............................................................................................................................. 3-12

Chapter 4 Programming

General Information ....................................................................................................... 4-1

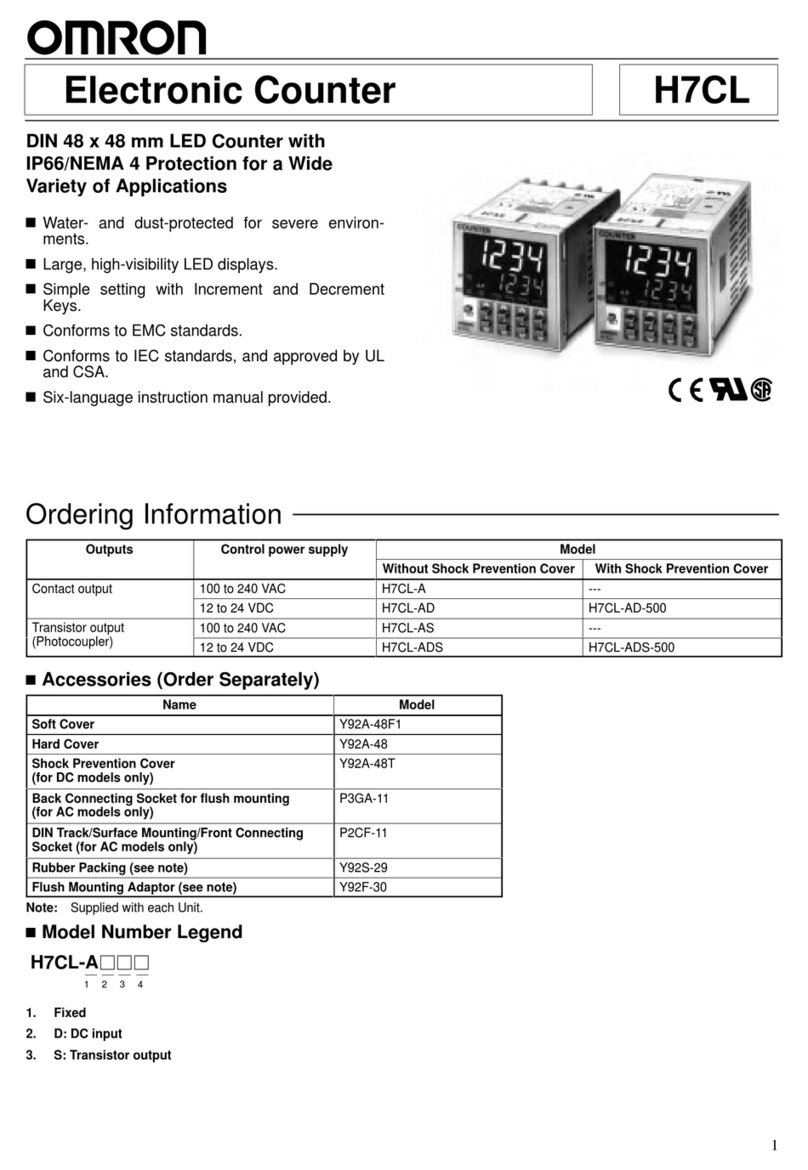

DIP Switches .................................................................................................................. 4-1

DIP Switch Settings ....................................................................................................... 4-2

GENERAL DEFINITIONS ............................................................................... 4-2

Communications Mode (DIP #8) ........................................................... 4-2

REMOTE Display Mode (DIP#7) ......................................................... 4-2

Addressing (DIP 1-6) ............................................................................. 4-3

Communicating with the Instrument ............................................................................. 4-4

RS-232 via USB Communications .................................................................... 4-5

RS-485 Port ........................................................................................................ 4-5

RS-485 Communications ................................................................................... 4-5

Configuring with REMOTE Display ............................................................................. 4-5

Configuring with the MODBUS Protocol ..................................................................... 4-5

Setting the Real Time Clock .............................................................................. 4-6

Changing the Default Instrument Parameters .................................................... 4-6

Running the Instrument ................................................................................................. 4-8

MANUAL Counting Mode ................................................................................ 4-9

AUTOMATIC Counting Mode ......................................................................... 4-9

Chapter 5 Maintenance Procedures

Safety ............................................................................................................................. 5-1

Calibration ..................................................................................................................... 5-1

Cleaning ......................................................................................................................... 5-1

Purge Test ...................................................................................................................... 5-1

Chapter 6 Ethernet Installation

Overview ........................................................................................................................ 6-1

Definitions of Terms Used ............................................................................................. 6-2

Preparing for Network Installation ................................................................................ 6-3

Equipment Required: ......................................................................................... 6-3

Software Required: ............................................................................................ 6-3

Additional Requirements: .................................................................................. 6-3

Configure Device ........................................................................................................... 6-4

Ethernet Port Configuration ............................................................................... 6-4

Straight-through Cat5 Setup: ................................................................. 6-4