5

Table of contents

Masthead........................................................................................................................................................................................ 4

Table of contents ............................................................................................................................................................................ 5

Safety alerts, visual presentation, and layout ................................................................................................................................. 7

1. Safety instructions ...................................................................................................................................................................... 8

General safety instructions ....................................................................................................................................................8

General electrical safety instructions ..................................................................................................................................... 8

General behaviour when handling the product ...................................................................................................................... 8

Intended use.......................................................................................................................................................................... 8

Persons authorized to use the product .................................................................................................................................. 9

Foreseeable misuse .............................................................................................................................................................. 9

Referenced documents ......................................................................................................................................................... 9

Prohibition of certain activities ...............................................................................................................................................9

Painting plastic components and seals.................................................................................................................................. 9

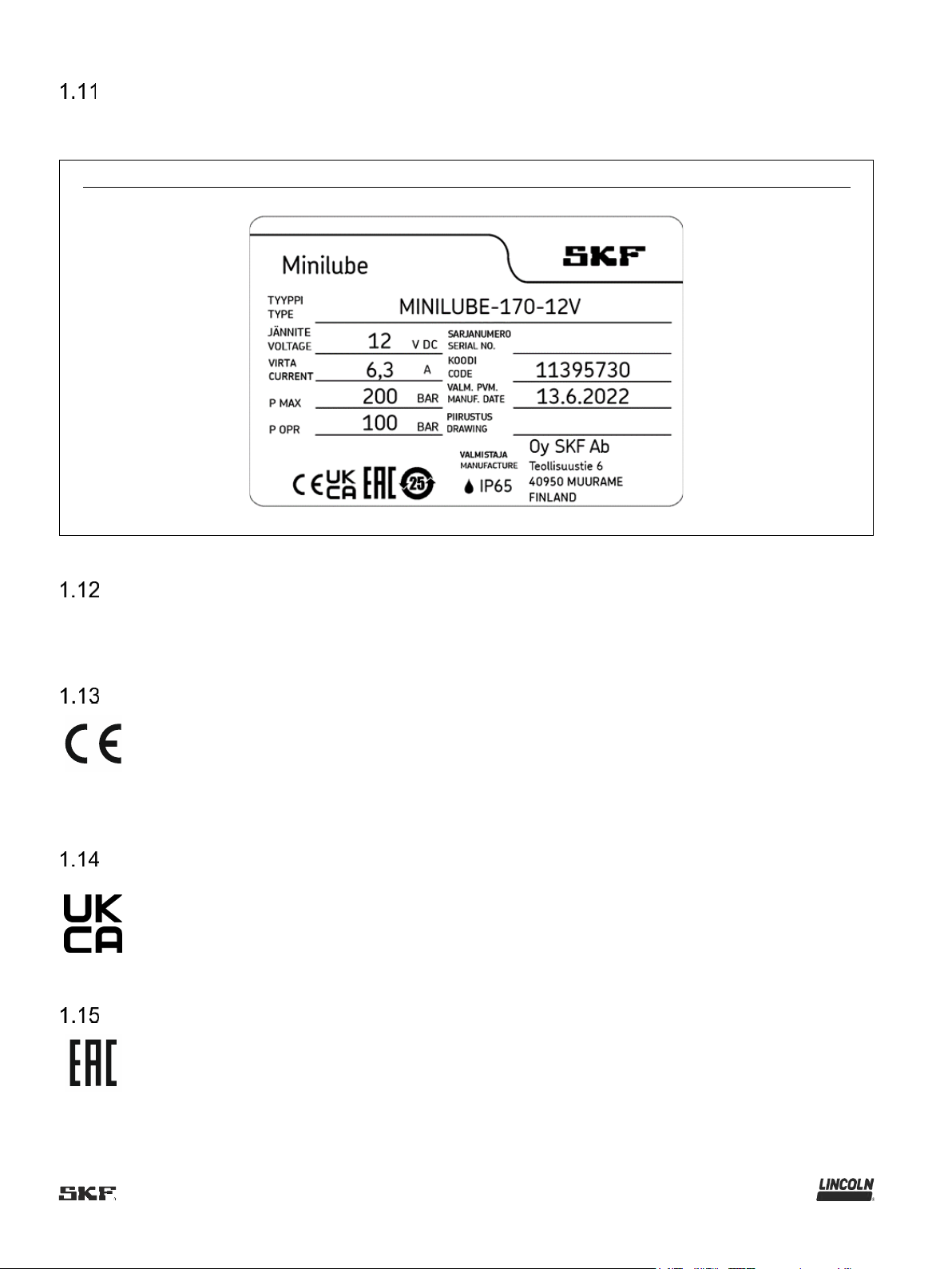

Safety markings on the product ...........................................................................................................................................9

Notes on the type plate...................................................................................................................................................... 10

Note on Low Voltage Directive ............................................................................................ Error! Bookmark not defined.

Note on Pressure Equipment Directive.............................................................................................................................. 10

Notes on CE marking ........................................................................................................................................................ 10

Notes related to the UKCA marking................................................................................................................................... 10

Notes on EAC mark........................................................................................................................................................... 10

Note on China RoHS mark ................................................................................................................................................ 11

Emergency shutdown ........................................................................................................................................................ 11

Assembly, maintenance, fault, repair................................................................................................................................. 11

First start-up, daily start-up................................................................................................................................................ 11

Residual risks .................................................................................................................................................................... 12

2. Lubricants ................................................................................................................................................................................. 13

General information ............................................................................................................................................................. 13

Material compatibility ........................................................................................................................................................... 13

Temperature properties ....................................................................................................................................................... 13

Aging of lubricants ............................................................................................................................................................... 13

Avoidance of faults and hazards.......................................................................................................................................... 13

Solid lubricants .................................................................................................................................................................... 13

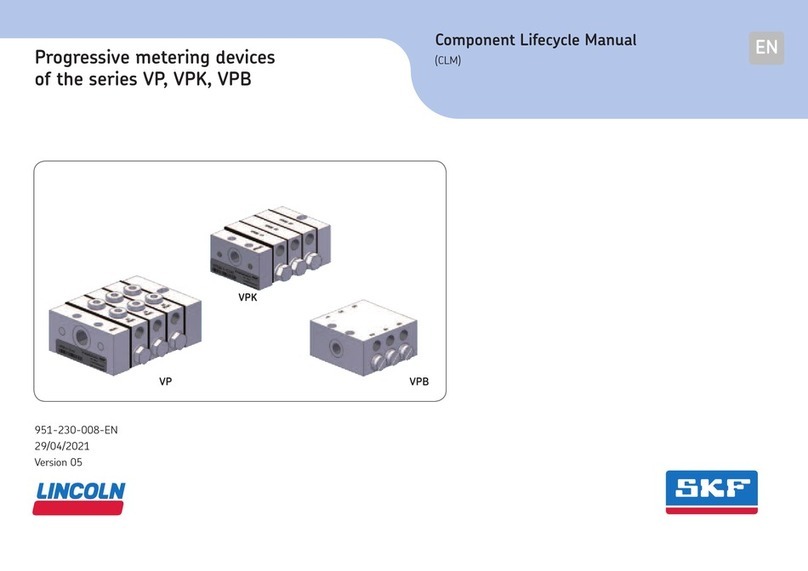

3. Overview, design & operation................................................................................................................................................... 14

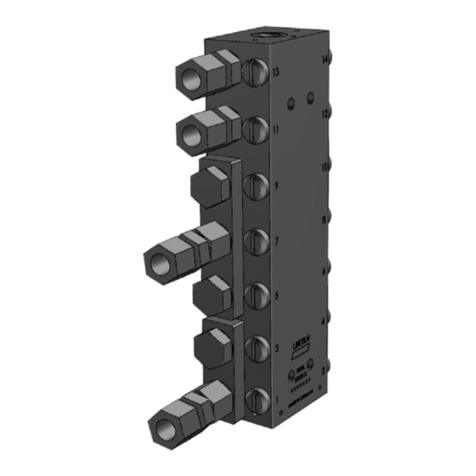

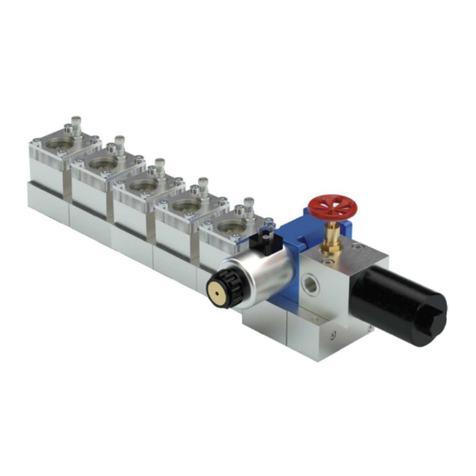

Main components ................................................................................................................................................................ 14

System diagram, SKF Minilube with internal ST104 control ................................................................................................ 15

System diagram, SKF Minilube with external ST102 control ............................................................................................... 16

4. MINILUBE WITH INTERNAL ST104 CONTROL...................................................................................................................... 17

LEDs.................................................................................................................................................................................... 17

Jumpers............................................................................................................................................................................... 18

Lubrication cycle settings, rotary switch T ........................................................................................................................... 19

Lubrication Cycle Schedule 1, Jumper A Open ......................................................................................................................... 19

Lubrication Cycle Schedule 2, Jumper A Closed....................................................................................................................... 19

Test button S ....................................................................................................................................................................... 20

Power failure........................................................................................................................................................................ 20

Electrical connections 3pump models with internal ST104 control ..................................................................................... 20

4.6.1 Supply voltage connection......................................................................................................................................... 20

4.6.2 Alarm output .............................................................................................................................................................. 21

4.6.3 Interlock input ............................................................................................................................................................ 21

4.6.4 Wiring diagram .......................................................................................................................................................... 21

5. Technical data .......................................................................................................................................................................... 22

Technical specification ........................................................................................................................................................ 22

Designation and order codes............................................................................................................................................... 22

6. Delivery, returns, storage.......................................................................................................................................................... 23

Delivery ............................................................................................................................................................................... 23

Return shipment .................................................................................................................................................................. 23

Storage................................................................................................................................................................................ 23

Storage temperature range ................................................................................................................................................. 23

Storage conditions for products filled with lubricant............................................................................................................. 23

6.5.1 Storage period up to 6 months .................................................................................................................................. 23