6

Table of contents

Imprint ................................................................................................5

Manufacturer......................................................................................5

Service ................................................................................................5

Training courses.................................................................................5

Warranty .............................................................................................5

Disclaimer............................................................................................5

Table of contents................................................................................6

Safety alerts, visual presentation, and layout................................7

1. Safety instructions.........................................................................8

1.1 General safety instructions ................................................... 8

1.2 General electrical safety instructions................................... 8

1.3 General behaviour when handling the product.................. 8

1.4 Intended use............................................................................ 8

1.5 Persons authorized to use the product............................... 8

1.6 Foreseeable misuse................................................................ 9

1.7 Referenced documents.......................................................... 9

1.8 Prohibition of certain activities ............................................. 9

1.9 Painting plastic components and seals ............................... 9

1.10 Safety markings on the product ........................................ 9

1.11 Note on the type plate......................................................... 9

1.12 Notes on CE marking........................................................... 9

1.13 Note on UKCA marking ....................................................... 9

1.14 Assembly, maintenance, fault, repair................................ 9

1.15 First start-up, daily start-up ............................................10

2. Lubricants.................................................................................... 11

2.1 General information............................................................. 11

2.2 Material compatibility...........................................................11

2.3 Temperature characteristics...............................................11

2.4 Ageing of lubricants..............................................................11

2.5 Avoidance of malfunctions and hazards............................11

3. Overview, functional description............................................... 12

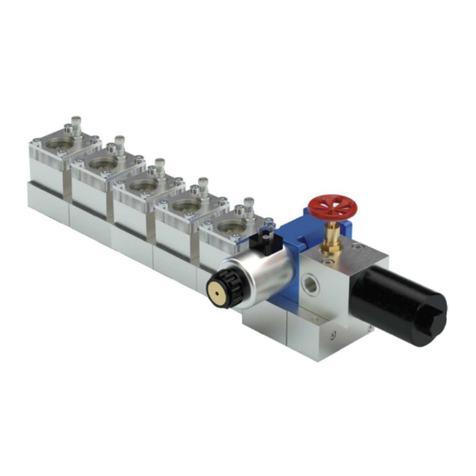

3.1 Description............................................................................. 12

3.1.1 General....................................................................... 12

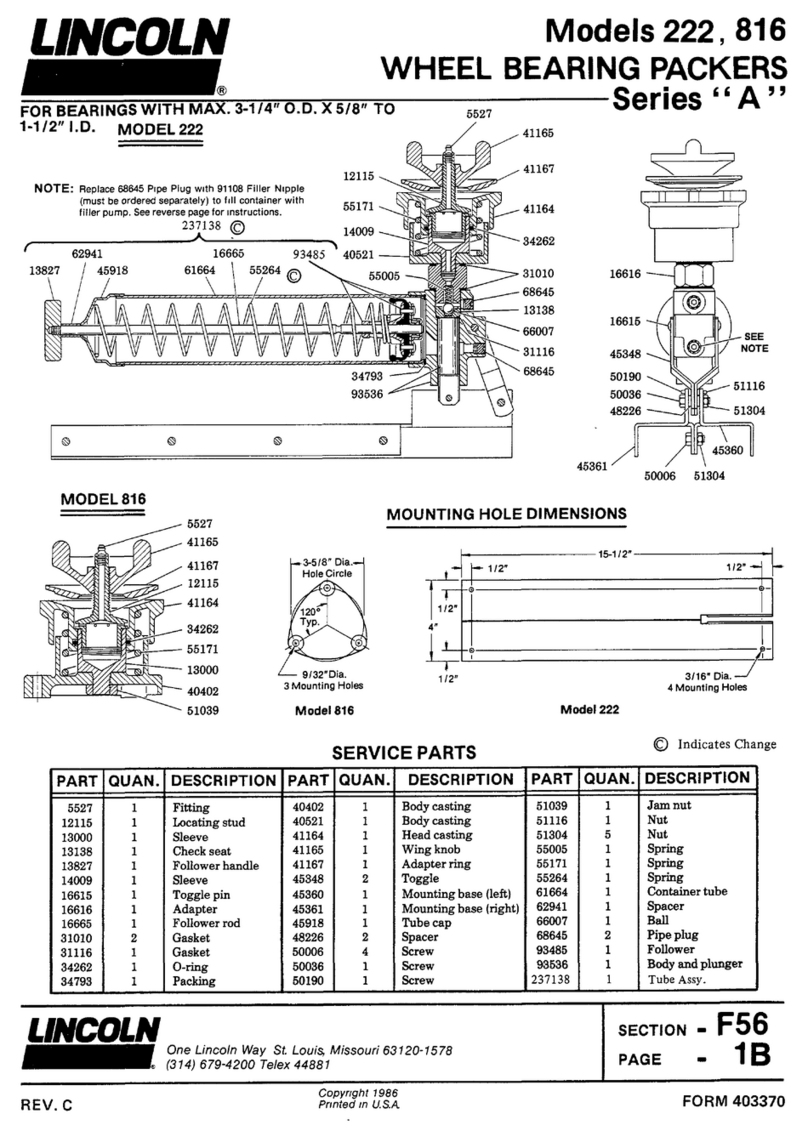

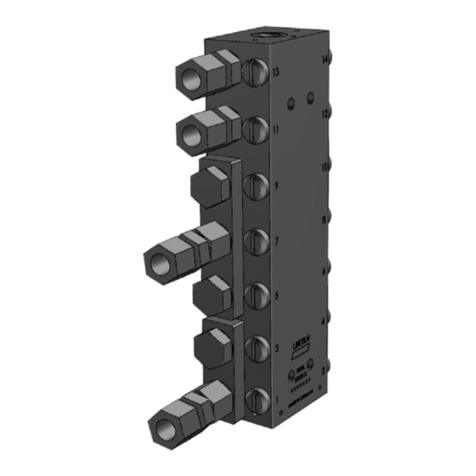

3.1.2 Construction.............................................................. 12

3.2 Function................................................................................. 14

4. Technical data ............................................................................. 15

5. Delivery, returns, storage.......................................................... 17

5.1 Delivery..................................................................................17

5.2 Return shipment................................................................... 17

5.3 Storage .................................................................................. 17

5.4 Storage temperature range................................................17

6. Assembly...................................................................................... 18

6.1 General................................................................................... 18

6.2 Positioning and installation.................................................18

6.2.1 Setup..........................................................................18

6.2.2 Assembly....................................................................18

6.3 Inlet connection .................................................................... 18

6.3.1 Oil inlet connection...................................................18

6.3.2 Pneumatic connection .............................................19

6.4 Outlet connection ................................................................. 20

6.4.1 Connection coaxial line / outlet port ......................20

6.4.2 Connection of the coaxial line to the projection

block...................................................................................... 20

6.5 Electrical connection ............................................................ 22

6.5.1 Solenoid valve ........................................................... 22

7. First start-up............................................................................... 23

7.1 Inspections prior to commissioning ................................... 23

7.2 Bleeding and commissioning.............................................. 23

7.2.1 Commissioning.......................................................... 23

7.2.2 Bleeding the micropump......................................... 24

7.2.3 Switching out a nozzle............................................. 24

7.3 Micropump flow rate adjustment....................................... 24

7.3.1 Adjustment with thumb wheel ............................... 24

7.3.2 Adjustment with metering ring .............................. 24

7.3.3 Neutralizing the micropump delivery .................... 24

7.4 pneumatic impulse generator ............................................ 26

7.5 Carrier air pressure regulator ............................................ 26

8. Operation..................................................................................... 27

8.1 Reservoir filling..................................................................... 27

9. Maintenance and repair............................................................. 28

10. Cleaning..................................................................................... 28

10.1 Basics................................................................................... 28

10.2 Interior cleaning................................................................. 28

10.3 Exterior cleaning ................................................................ 28

11. Faults, causes, and remedies ................................................. 29

12. Shutdown, disposal.................................................................. 31

12.1 Temporary shutdown........................................................ 31

12.2 Permanent shutdown, disassembly ................................ 31

12.3 Disposal ............................................................................... 31

13. Spare parts ............................................................................... 32