5

Table of contents

Masthead ...............................................................................................4

Table of contents..................................................................................5

Safety alerts, visual presentation, and layout.................................7

1. Safety instructions...........................................................................8

1.1 General safety instructions......................................................8

1.2 General electrical safety instructions.....................................8

1.3 General behaviour when handling the product ...................8

1.4 Intended use...............................................................................8

1.5 Persons authorized to use the product.................................8

1.6 Foreseeable misuse ..................................................................9

1.7 Referenced documents ............................................................9

1.8 Prohibition of certain activities ...............................................9

1.9 Painting plastic components and seals .................................9

1.10 Safety markings on the product ..........................................9

1.11 Note on the type plate ...........................................................9

1.12 Notes on CE marking .............................................................9

1.13 Note on Low Voltage Directive.......................................... 10

1.14 Note on Pressure Equipment Directive........................... 10

1.15 Note on UKCA marking.......................................................10

1.16 Note on EAC marking.......................................................... 10

1.17 Note on China RoHS mark................................................. 10

1.18 Emergency shutdown ......................................................... 10

1.19 Assembly, maintenance, fault, repair............................... 10

1.20 First start-up, daily start-up.............................................. 10

1.21 Residual risks........................................................................ 11

2. Lubricants ...................................................................................... 12

2.1 General information............................................................... 12

2.2 Material compatibility ............................................................12

2.3 Temperature characteristics................................................ 12

2.4 Ageing of lubricants ............................................................... 12

2.5 Avoidance of malfunctions and hazards ............................ 12

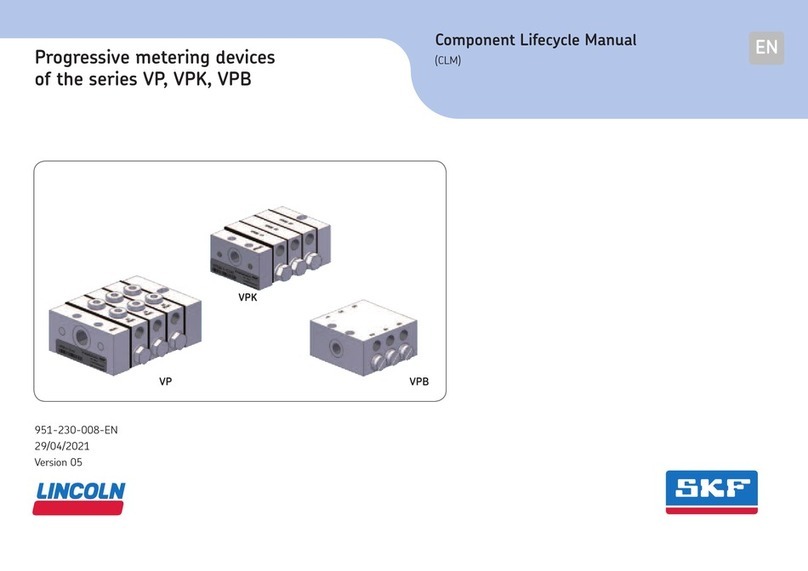

3. Overview, functional description................................................ 13

3.1 Principle of minimal quantity lubrication........................... 13

3.2 Principle of aerosol action .................................................... 13

3.3 General functioning and structure...................................... 13

3.3.1 Minimal quantity lubrication .................................... 14

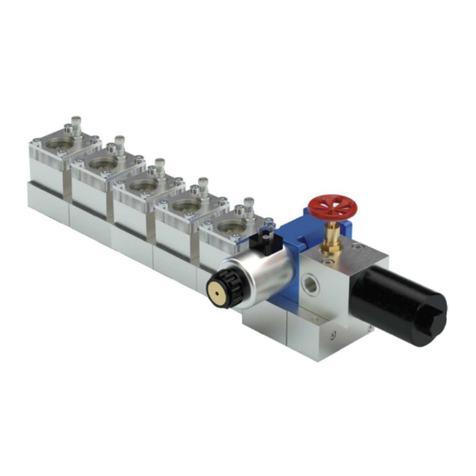

3.4 Main components of a UFD minimal quantity lubrication

system .............................................................................................14

3.4.1 Aerosol generator ...................................................... 14

3.4.2 Control unit ................................................................. 14

3.4.3 Communication interface ......................................... 15

3.4.4 Flow sensor.................................................................15

3.4.5 Lubricant level gauge and fill level monitoring..... 15

3.4.6 Main air valve (compressed air connection).......... 15

3.4.7 Pressure gauge .......................................................... 15

3.4.8 Fine filter for compressed air................................... 15

3.4.9 Lubricant drain valve................................................. 15

3.4.10 Pressure limiting valve ........................................... 15

3.5 Version-specific components............................................... 16

3.5.1 PROFIBUS communication interface...................... 16

3.5.2 PROFINET communication interface...................... 18

3.5.3 Automatic filling pump.............................................. 19

3.5.4 Automatically controlled bypass valve – bypass

control.....................................................................................19

3.6 System versions and type identification code................... 21

3.6.1 Minimal quantity lubrication systems with one or

two aerosol generators........................................................22

4. Technical data ............................................................................... 42

4.1 Type identification code.........................................................43

4.1.1 UFD10..........................................................................43

4.1.2 UFD20..........................................................................43

5. Delivery, returns, storage............................................................ 44

5.1 Delivery.....................................................................................44

5.2 Return shipment.....................................................................44

5.3 Storage.....................................................................................44

5.4 Storage temperature range .................................................44

5.5 Storage conditions for products filled with lubricant....... 44

5.5.1 Storage period up to 6 months...............................44

5.5.2 Storage period between 6 and 18 months........... 44

5.5.3 Storage period more than 18 months...................44

5.6 Declaration of decontamination ..........................................44

6. Assembly ........................................................................................ 45

6.1 General.....................................................................................45

6.2 Installation location................................................................45

6.3 Mechanical connection ..........................................................45

6.3.1 Minimum mounting dimensions .............................45

6.4 Tightening torques................................................................. 45

6.5 Assembly holes .......................................................................45

6.5.1 Attachment of the MQL systems.............................46

6.6 Installation dimensions and minimum mounting

dimensions......................................................................................46

6.6.1 MMS UFD10-1-100000 und UFD10-1-101000

.................................................................................................46

6.6.2 MMS UFD10-1-200000 und UFD10-1-201000

.................................................................................................47

6.6.3 MMS UFD10-1-110000 und UFD10-1-111000

.................................................................................................48

6.6.4 MMS UFD10-1-210000 und UFD10-1-211000

.................................................................................................49

6.6.5 MMS UFD20-1-100000 und UFD20-1-101000

.................................................................................................50

6.7 Connection of aerosol lines................................................... 51

6.7.1 General instructions for the connection of the

aerosol lines...........................................................................51

6.7.2 Connecting the aerosol lines to an MQL system

with bypass control...............................................................52

6.7.3 Connection of the aerosol lines to an optional SKF

aerosol monitor (AM1000) .................................................52

6.8 Electrical connection .............................................................. 54

6.8.1 Connector pin assignment for standard

configurations........................................................................54

6.8.2 Possible connections by the customer with UFD10-

1-1XX000 with PROFIBUS................................................. 54

6.8.3 Possible connections by the customer with UFD10-

1-2XX000 with PROFINET ................................................. 55

6.8.4 Possible connections by the customer with UFD10-

1-20000 / UFD10-1-201000........................................... 56

6.8.5 Possible connections by the customer with UFD10-

1-110000 / UFD10-1-111000 ........................................57

6.8.6 Possible connections by the customer with UFD10-

1-210000 / UFD10-1-211000 ........................................58

6.8.7 Possible connections by the customer to an

optional SKF aerosol monitor (AM1000) .........................59

6.9 Pneumatic connection...........................................................60