Page 3 of 20

Subject to modifications

User Manual

OperationInstructions

2.2EN-20004-C11

LINCOLNGmbH •Postfach 1263• D-69183Walldorf •Tel+49 (6227)33-0 •Fax +49(6227) 33-259

Table of Contents

Page

Introduction

Explanation of Symbols Used ............................................ 4

User’s Responsibility ......................................................... 4

Environmental Protection .................................................. 4

Service .............................................................................. 4

Safety Instructions

Appropriate Use ................................................................ 5

Suitable Lubricants ...................................................... 5

General Safety Instructions ............................................... 5

Accident Prevention Regulations ....................................... 5

Operation, Maintenance, Repair ........................................ 5

Installation ......................................................................... 5

Installation

Connection Fittings, Screw-Type ....................................... 6

Inlet tube fittings ........................................................... 6

Outlet tube fittings ........................................................ 6

Hose fittings ................................................................. 6

High-pressure Hoses ................................................... 6

Control piston – Closure plugs ..................................... 6

Description

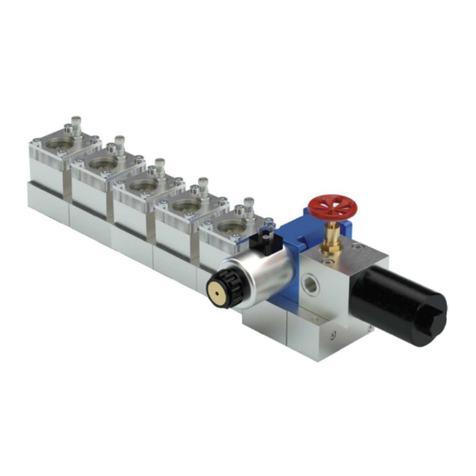

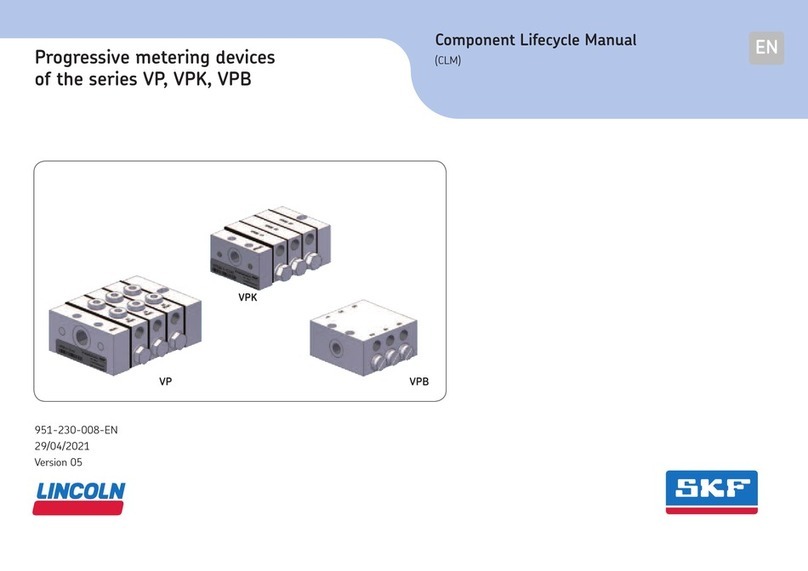

Progressive Metering Device Model SSVL ........................ 7

General ........................................................................ 7

Features of a Progressive Metering Device ................. 7

Rating .......................................................................... 7

Page

Operation

Applications ........................................................................ 8

Lubricant Distribution within the Metering Device ............ 10

Phase 1 + 2 ................................................................ 10

Phase 3 - 5 ................................................................. 11

Monitoring of the Operation ............................................. 12

System-dependent monitoring .................................... 12

Visual monitoring ........................................................ 12

Electrical monitoring ................................................... 13

Pressure relief valve ................................................... 13

Determining the Lubricant Output

byCombining Outlets ....................................................... 14

Outputs ....................................................................... 14

Outlet fittings .............................................................. 14

Troubleshooting ............................................................. 15

Technical Data

Rating .............................................................................. 17

Dimensions ...................................................................... 17

Tightening torques ........................................................... 17

Lines ................................................................................ 17

Spare Parts and Kits ...................................................... 18

EC Declaration of incorporation ................................... 19

Lincoln worldwide .......................................................... 20

Further Information can be found in the following manuals:

Technical Description Quicklub - Pump 203

Technical Description for “Electronic Control Units” of pump 203:

Printed-Circuit Board 236-13857-1 - Model H 1)

Printed-Circuit Board 236-13862-1 - Model V10 - V13 1)

Printed-Circuit Board 236-13870-3 - Model M 08 - M 23 1)

Installation Instructions

Parts Catalogue

List of Lubricants

Planning and Layout of Quicklub Progressive Systems

1) The model designation of the printed-circuit board is part of the pump model designation indicated on the pump nameplate,

e. g. : P 203 - 2XN - 1K6 - 24 - 1A1.10 - V10