LINCOLN GmbH Postfach 1263 D-69183 Walldorf Tel +49 (6227) 33-0 Fax +49 (6227) 33-259

Page 4 from 15

Owner Manual

Technical Description

2.6A-20004-B96

Subject to change without notice

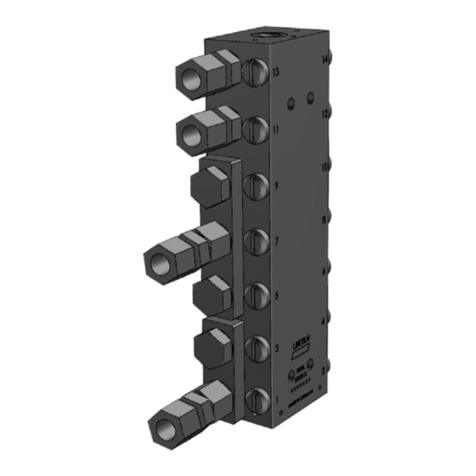

Printed Circuit Board , M 16 - M 23*

Applications

1193b95

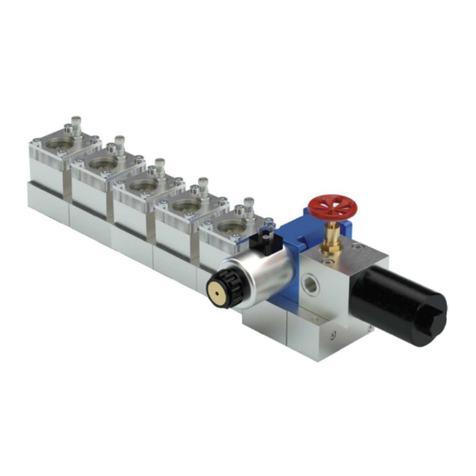

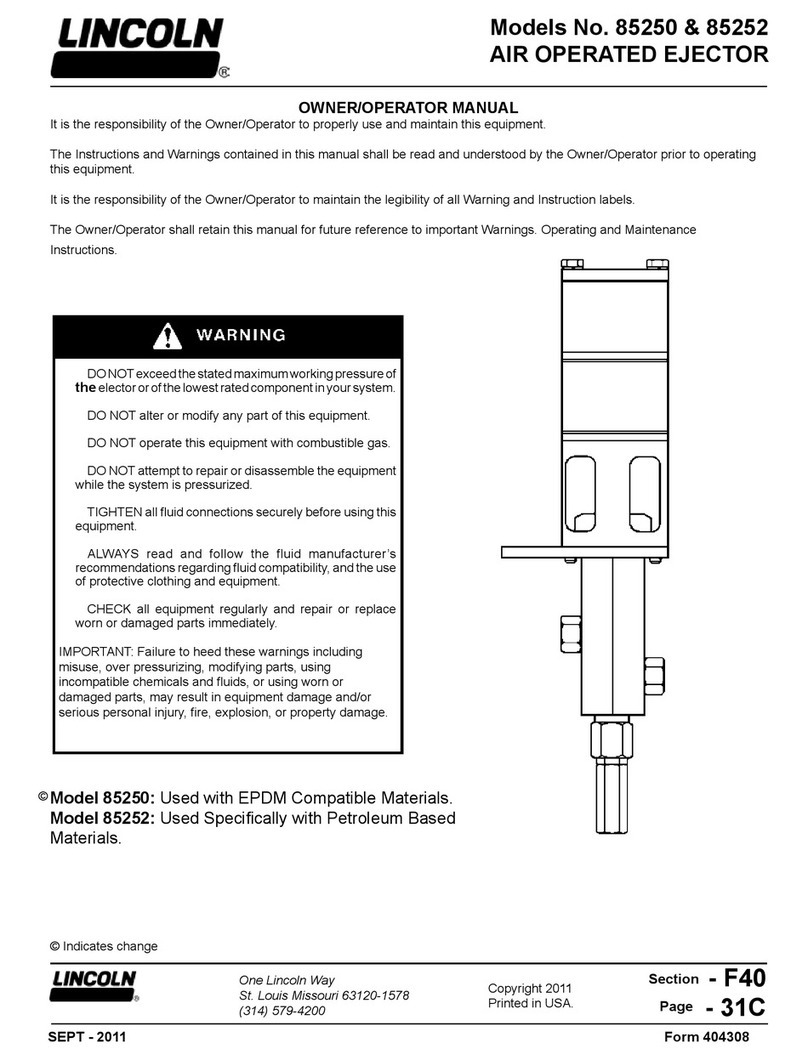

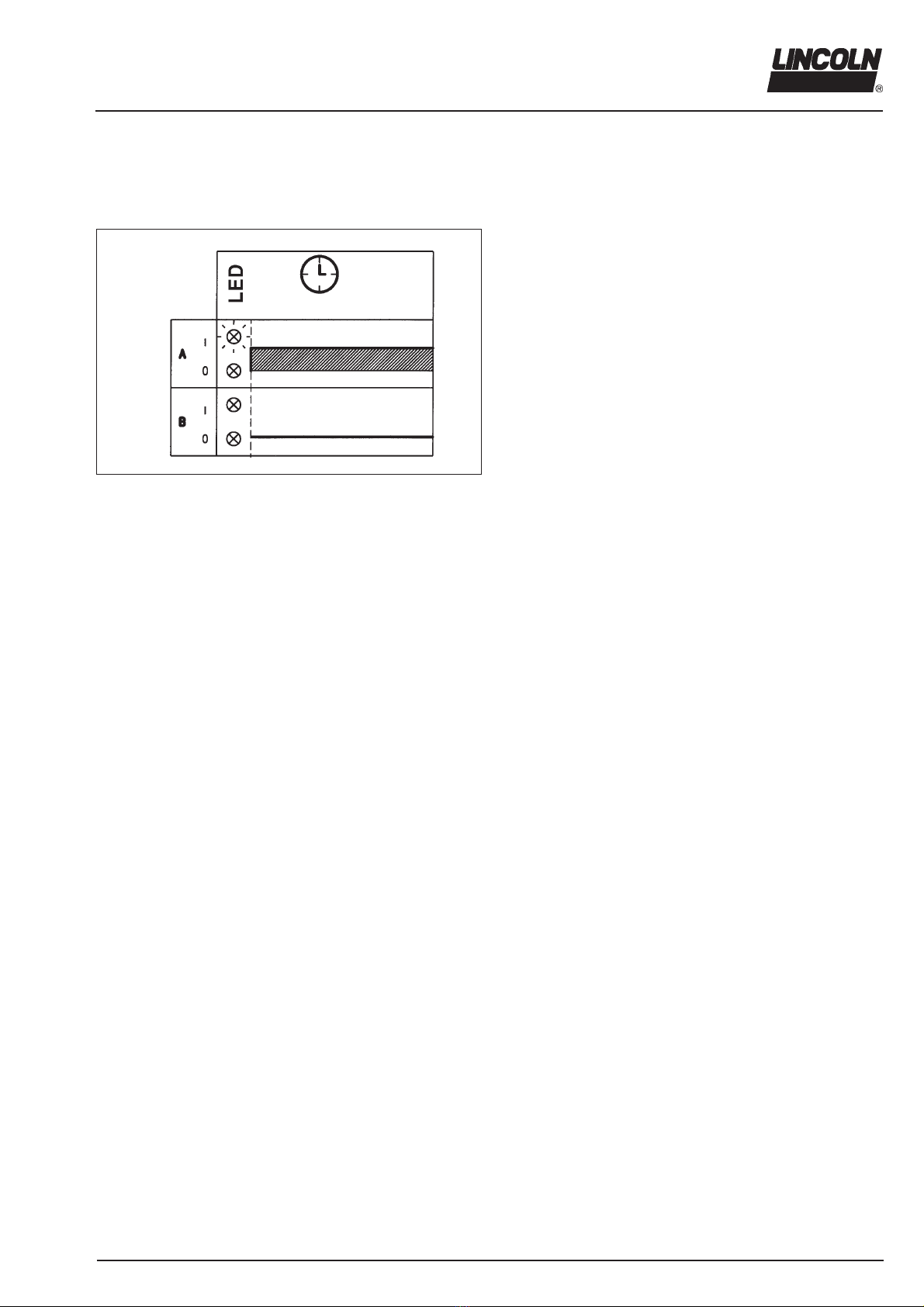

Fig. 1 - Supply voltage and machine contact

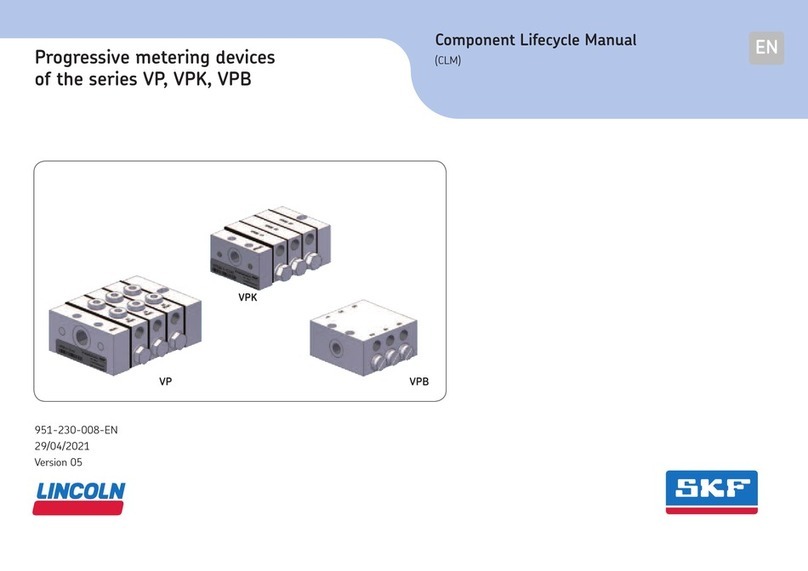

Possibilities of use

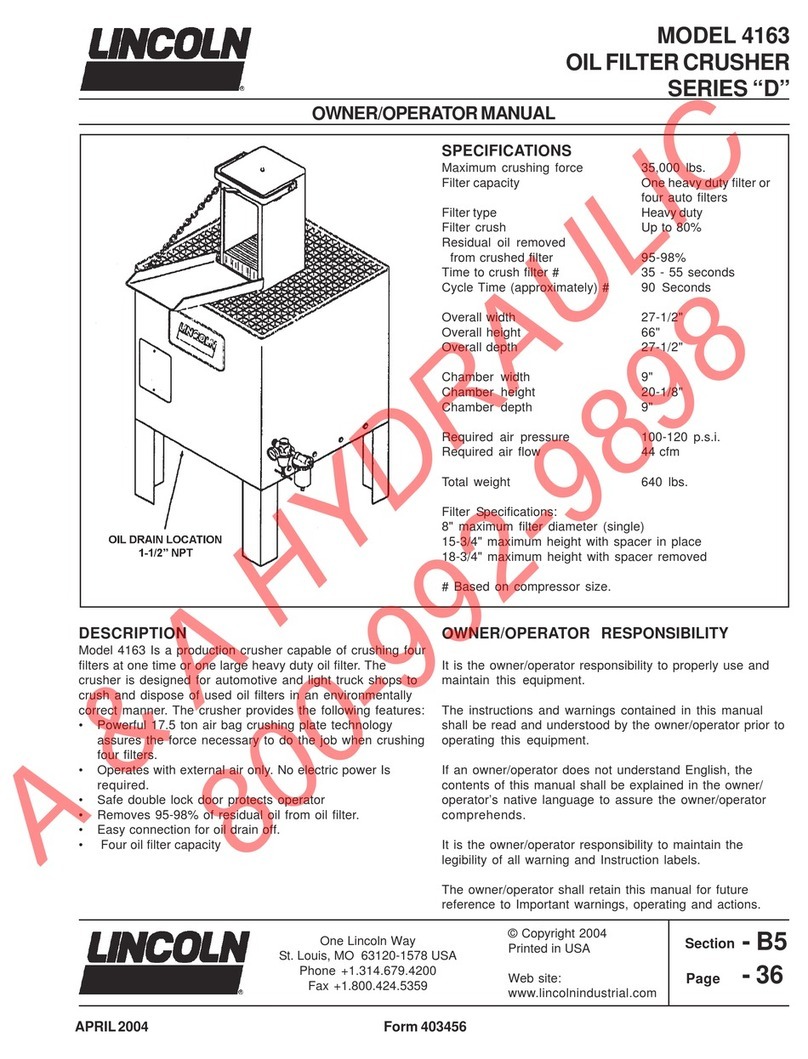

Lubrication cycles

- as a function of the machine operating hours and

-in addition, as a function of add-on units, auxiliairy units, etc.

which temporarily run during the machine operating hours and

must be lubricated only within their running time.

The power supply (+ and - ) is applied (jumper 15/30, Fig. 3, has

been removed). When the machine contact (external contact) is

switched on, the centralized lubrication system is ready for ope-

ration.

Indication of the time of availability: external relay 1 (Fig.1) has

picked up, LED (Fig.11) is lit.

Advantages

The central lubrication system is monitored, i.e. the readiness for service and faults are indicated (industrial applications

: permanent signal, see LED fig.11).

Note: Applications for commercial vehicles and industrial applications with flashing fault signal : refer to Technical Descrip-

tion of printed circuit board 236-13870-1, models M 00 - M 15

The following functions and operations are monitored and indicated as a fault in the case of a malfuncion.

Pump:

Function of the drive motor

Supply voltage failure - no lubrication

Pump element does not suppply - no lubrication

Reservoir empty (if low-level control not available) - no lubrication

Note: The fault is only indicated when the reservoir is complete-

ly empty and as soon as the pump element stops dispensing

the lubricant.

Reservoir empty (when low-level control available) - The lubricati-

on cycle occurs until the end of the operating time.

Note:The fault is indicated when the reservoir is empty, but if the

pump element is still surrounded with lubricant.

*M 16 - M 23 is the designation of the respective version of the printed circuit board (see Combinations of the jumper

positions, page 15). It is part of the pump type designation code mentioned on the nameplate of each pump.

System:

Lubrication point or metering device blocked

Main line leaking (from pump to the monitored metering device)

Air bubbles in the grease

Lubrication circuit 1 and/or - if any- lubrication circuit 2 mal-

functioning

1 - external relay

2 - machine contact

3 - Push for additional lubrication