5

Table of contents

Classification as simple electrical equipment in accordance with

EN 60079-14, No. 16.4......................................................2

Explosion protection marking in accordance with Directive

2014/34/EU ..........................................................................3

Combination of the SMBM flow limiters with electrical

attachments ..........................................................................3

Masthead.............................................................................................4

Table of contents ...............................................................................5

Safety alerts, visual presentation, and layout................................7

1. Safety instructions ........................................................................8

1.1 General safety instructions ....................................................8

1.2 General behaviour when handling the product...................8

1.3 Intended use ............................................................................8

1.4 Persons authorized to use the product................................8

1.5 Foreseeable misuse ................................................................9

1.6 Referenced documents...........................................................9

1.7 Prohibition of certain activities..............................................9

1.8 Painting plastic components and seals ................................9

1.9 Safety markings on the product............................................9

1.10 Notes on the type plate........................................................9

1.11 Notes on CE marking ........................................................ 10

1.12 Note on Low Voltage Directive ........................................ 10

1.13 Note on Pressure Equipment Directive .......................... 10

1.14 Emergency shutdown........................................................ 10

1.15 Assembly, maintenance, fault, repair.............................. 10

1.16 First start-up, daily start-up ............................................ 10

1.17 Special safety instructions regarding explosion

protection ..................................................................................... 10

1.18 Expiry of the ATEX approval............................................. 11

1.19 Operation in explosion-protected areas......................... 11

1.20 Explosion protection marking .......................................... 11

1.21 Inspections prior to delivery ............................................. 11

1.22 Briefing of external technicians ....................................... 11

1.23 Provision of personal protective equipment .................. 11

1.24 Operator obligations.......................................................... 11

1.24.1 Determination of hazards..................................... 11

1.24.2 Explosion protection measures............................ 12

1.24.3 Provision of necessary information..................... 12

1.24.4 Instruction and qualification obligations............. 12

1.25 Explosion protection marking according to Directive

2014/34/EU................................................................................. 12

1.26 Residual risks...................................................................... 13

1.27 Residual ATEX risks........................................................... 13

2. Lubricants.....................................................................................14

2.1 General information............................................................. 14

2.2 Selection of lubricants ......................................................... 14

2.3 Material compatibility .......................................................... 14

2.4 Temperature properties...................................................... 14

2.5 Aging of lubricants ............................................................... 15

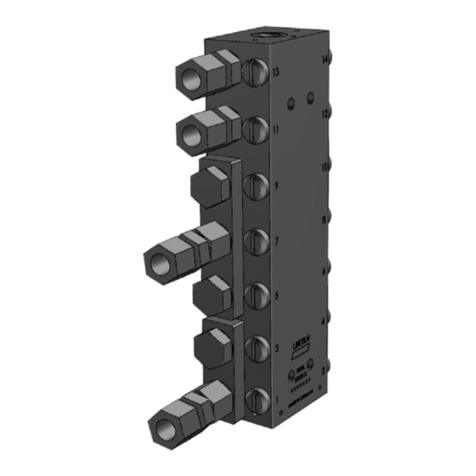

3. Overview, functional description ...............................................16

3.1 Type identification code of flow limiters of series SMBM16

3.1.1 Definition of the type and design ........................... 16

3.1.2 Definition of the electrical port and the plug-in

nozzles.................................................................................. 17

3.2 Plug-in nozzle table SMBM-X D

1

....................................... 19

3.3 Plug-in nozzle table SMBM-V with D

1

and D

2

................. 20

3.4 Ordering a complete flow limiter assembly...................... 21

3.5 Application............................................................................. 22

3.6 Functional description ......................................................... 22

3.7 Example of a circulating-oil- lubrication system with flow

limiter of series SMBM-X .......................................................... 25

3.8 Example of a circulating-oil- lubrication system with flow

limiter of series SMBM-V .......................................................... 26

4. Technical data..............................................................................27

4.1 General technical data SMBM............................................ 27

4.2 Signal transmitter 24-1072-2125 for flow indicator .... 28

4.3 Pulse generator 2340-00000091 for gear-type flow

indicator........................................................................................ 28

4.4 Electrical changeover valve 24-1254-3437 for switching

from start-up operation to normal operation ........................ 29

4.5 Oil filter .................................................................................. 29

4.6 Plug-in nozzle table SMBM-X D

1

...................................... 29

4.7 Plug-in nozzle table SMBM-V with D

1

and D

2

................. 30

4.8 Calculation of the resulting oil volumetric flow................ 31

4.8.1 Diagram for determination of the nozzle index ... 31

4.8.2 Diagram for determination of the correction factor

for the volumetric flow of the oil ...................................... 32

4.8.3 Determination example........................................... 33

5. Delivery, returns, storage ..........................................................34

5.1 Delivery.................................................................................. 34

5.2 Return shipment .................................................................. 34

5.3 Storage.................................................................................. 34

5.4 Storage temperature range ............................................... 34

5.5 Declaration of decontamination......................................... 34

6. Assembly ......................................................................................35

6.1 General information............................................................. 35

6.2 Minimum mounting dimensions ........................................ 35

6.3 Assembly drawings SMBM-X............................................. 36

6.3.1 SMBM-X00 without gear-type flow indicator,

without signal transmitter................................................. 36

6.3.2 SMBM-X22 with signal transmitter ...................... 36

6.3.3 SMBM-X01/X02/X03 with gear-type flow indicator

.............................................................................................. 37

6.3.4 SMBM-X11/X12/X13 with gear-type flow indicator

and pulse generator........................................................... 37

6.3.5 SMBM-X51/X52/X53 with gear-type flow indicator

and signal transmitter ....................................................... 38

6.3.6 Filter unit for SMBM-X............................................ 38

6.3.7 Base plates for SMBM-X ........................................ 39

6.4 Assembly drawings SMBM-V............................................. 41

6.4.1 SMBM-V00 without gear-type flow indicator,

without signal transmitter................................................. 41

6.4.2 SMBM-V22 with signal transmitter ...................... 41

6.4.3 SMBM-V01/V02/V03 with gear-type flow

indicator, without pulse generator................................... 42

6.4.4 SMBM-V11/V12/V13 with gear-type flow indicator

and pulse generator........................................................... 42

6.4.5 SMBM-V51/V52/V53 with gear-type flow indicator

and signal transmitter ....................................................... 43

6.4.6 Filter unit for SMBM-V............................................ 43

6.4.7 Changeover valve for SMBM-V.............................. 44

6.4.8 Base plates for SMBM-V ........................................ 45

6.5 Assembling the flow limiters SMBM.................................. 47

6.6 Mechanical connection options SMBM ............................. 48